Pulled core oblique roof structure and injection mold

A technology of sloping roof and sloping roof group, which is applied in the field of injection molds, can solve the problems of difficult production and installation, damage of ribs and fixed blocks, and complex mold structure, so as to achieve ingenious structural design, reduce mold opening time, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

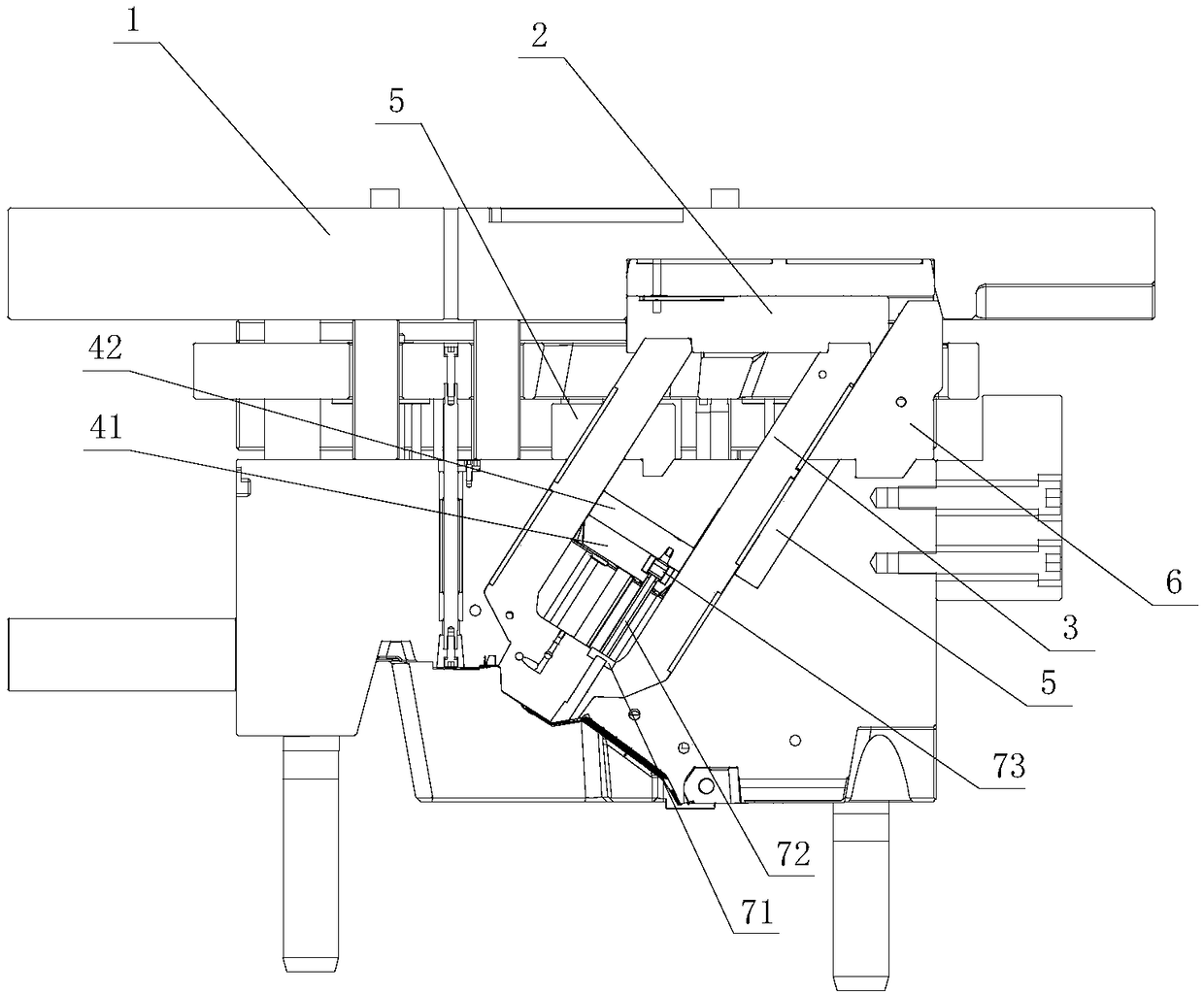

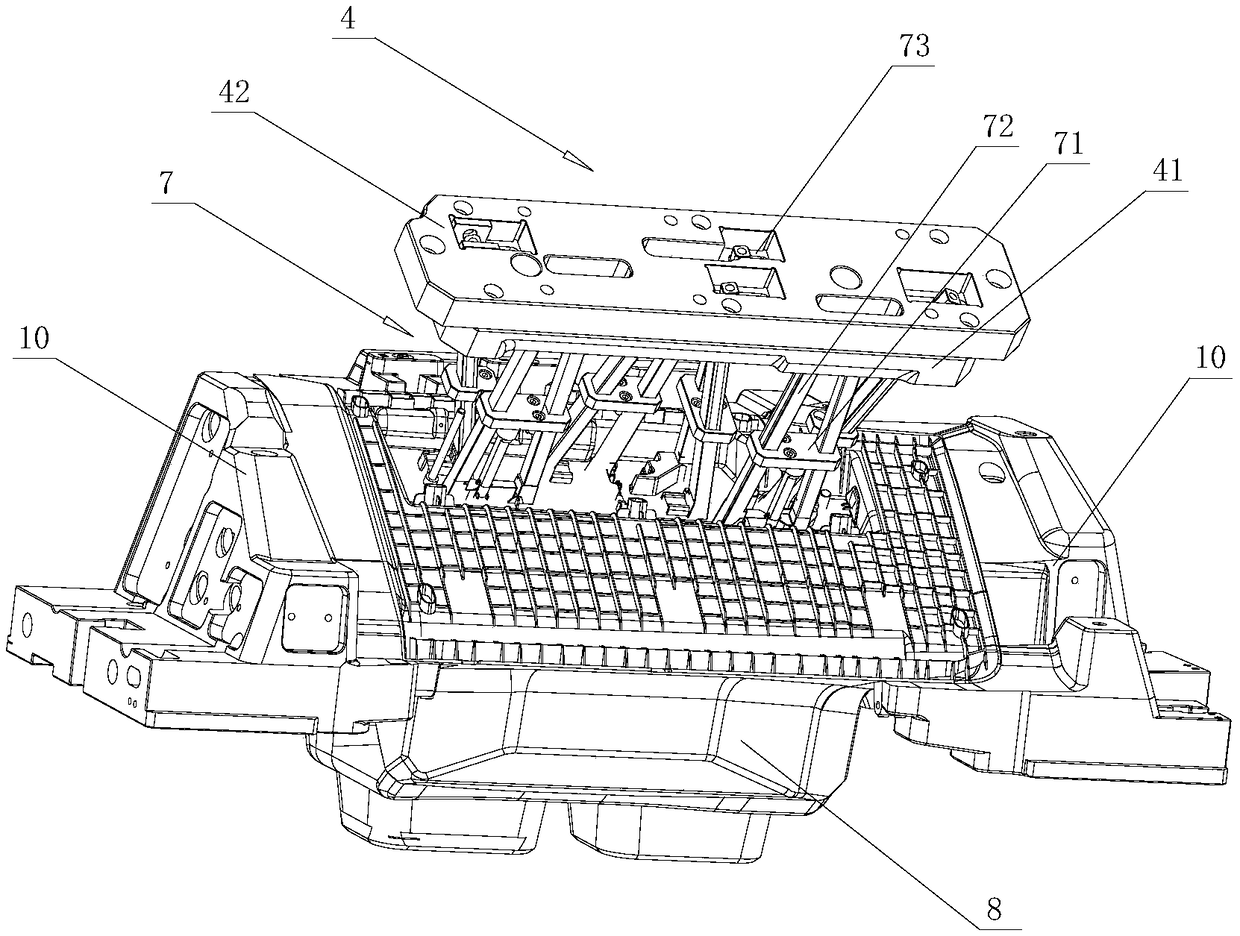

[0022] Embodiment 1, combining figure 1 and figure 2 , a core-pulling inclined roof structure, including a rear mold top plate 1 arranged on the outside of the rear mold, a core-pulling slide seat 2, a core-pulling seat 3 arranged in the rear mold, a core-pulling needle plate 4 and a guide block 5, the core-pulling The sliding seat 2 is fixedly installed on the rear mold top plate 1, and the rear mold top plate 1 is connected with the rear mold through a draw hook, and at the same time, the rear mold is connected with the front mold through the draw hook. The side adjacent to the core-pulling slide 2 and the core-pulling base 3 is provided with a chute, and one end of the core-pulling base 3 extends into the chute of the core-pulling slide 2 to slide and cooperate with it. When the mold moves, the core-pulling seat 3 is driven to move relative to the rear mold, and at the same time, the core-pulling seat 3 and the core-pulling slide seat 2 slide relative to each other. A we...

Embodiment 2

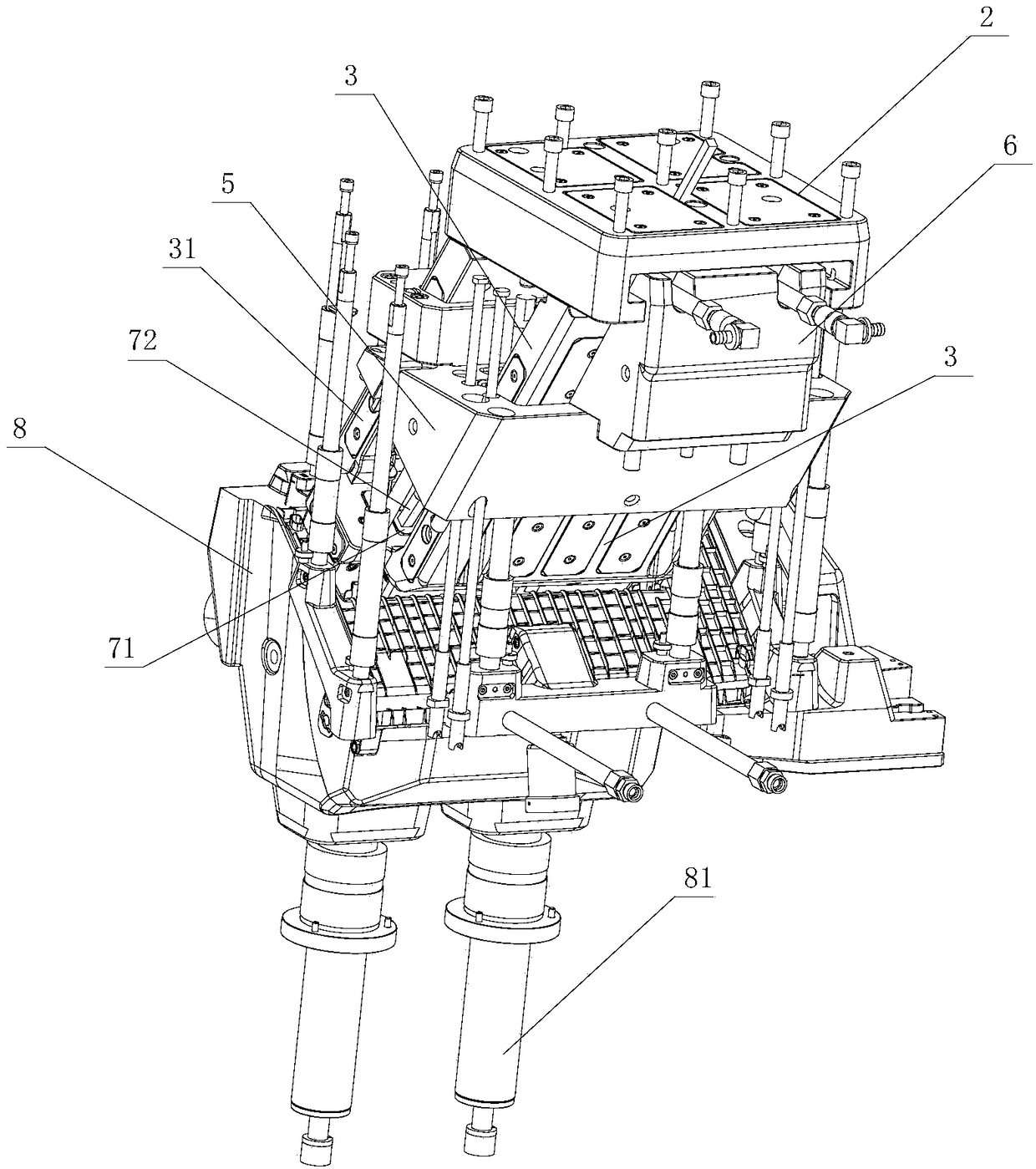

[0026] Example 2, combined with Figure 3 to Figure 5 , an injection mold, comprising a front mold, a back mold and a pull hook, characterized in that the back mold is provided with the above-mentioned core-pulling inclined roof structure, and the front mold is also provided with a front mold top block 8, and the front mold is provided with a The front mold ejector rod 81 that front mold top block 8 ejects from the front mold. Front mold is positioned at the both sides of its mold cavity, and two front mold slide blocks 10 are symmetrically arranged, and described front mold slide block 10 is slidably matched with front mold, and front mold slide block 10 is driven its movement by slide block oil cylinder, and front mold slide block 10 After opening the mold with the rear mold, after the two front mold sliders 10 move to both sides and withdraw from the undercut, the front mold top block 8 can eject the product from the front mold, and the ejected product remains in the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com