Adjusting-calibrating-positioning method for PC board boring needle ringer

A positioning method, PC board technology, applied in the measurement of positioning in the boring machine/drilling machine, components of the boring machine/drilling machine, drilling/drilling equipment, etc., can solve problems such as acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

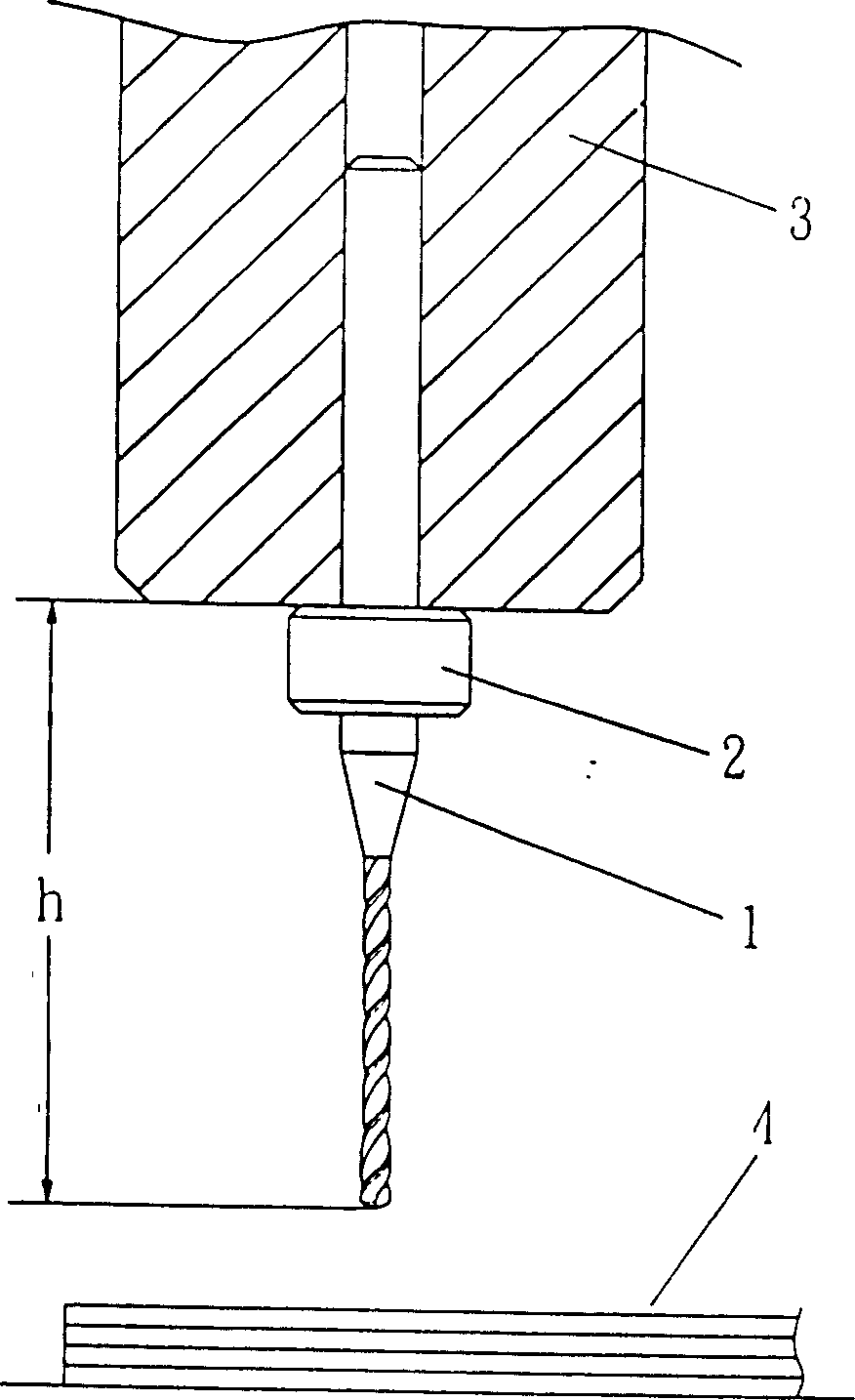

[0026] The adjustment, calibration and positioning method of the PC board drill pin collar of the present invention, such as figure 1 As shown, the main purpose is to ensure that the collar 2 on the drill 1 can be positioned at the standard upper ring height h. The standard upper ring height h refers to the preset distance between the bottom of the collar 2 and the tip of the drill 1 Set an absolute distance.

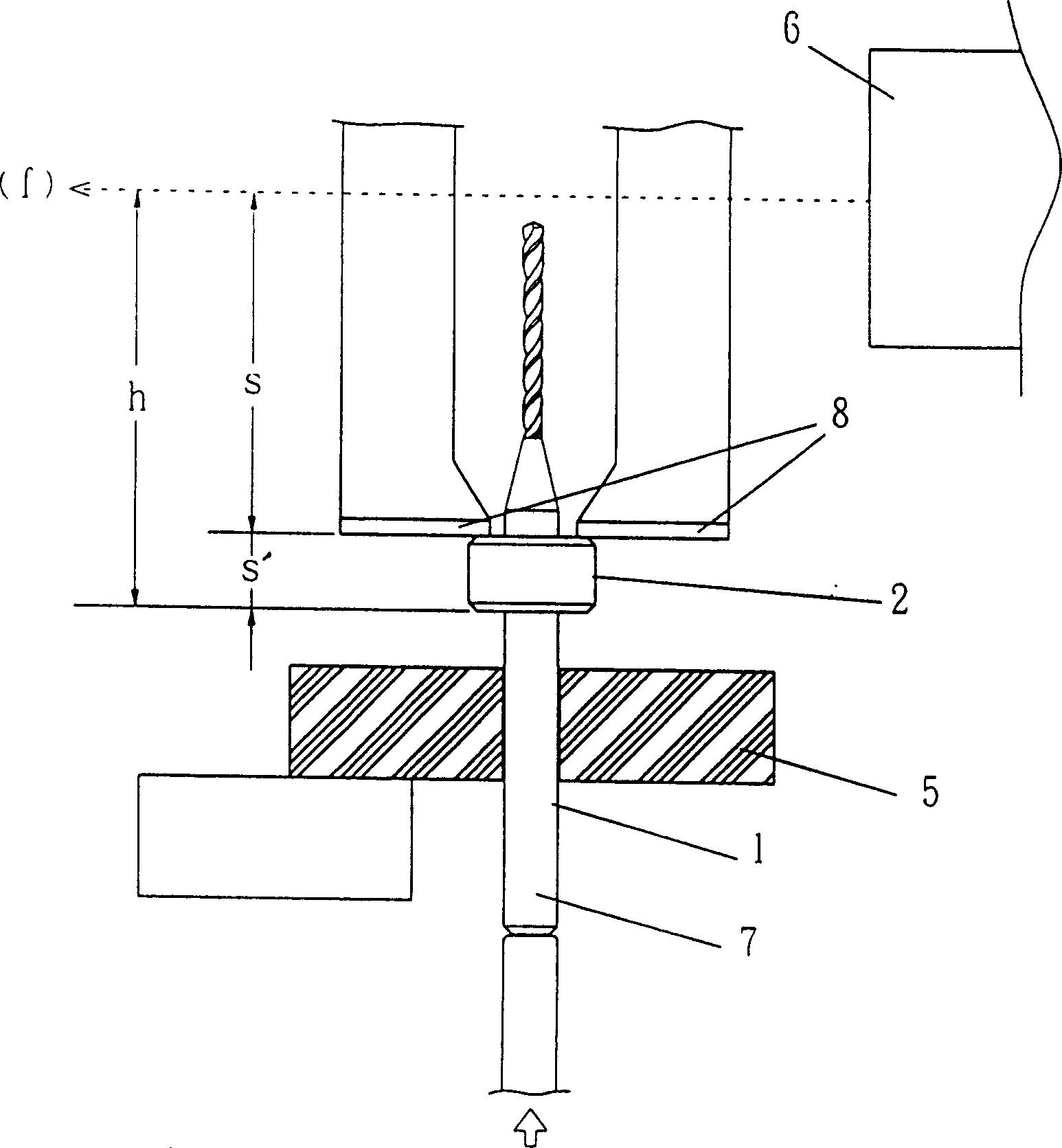

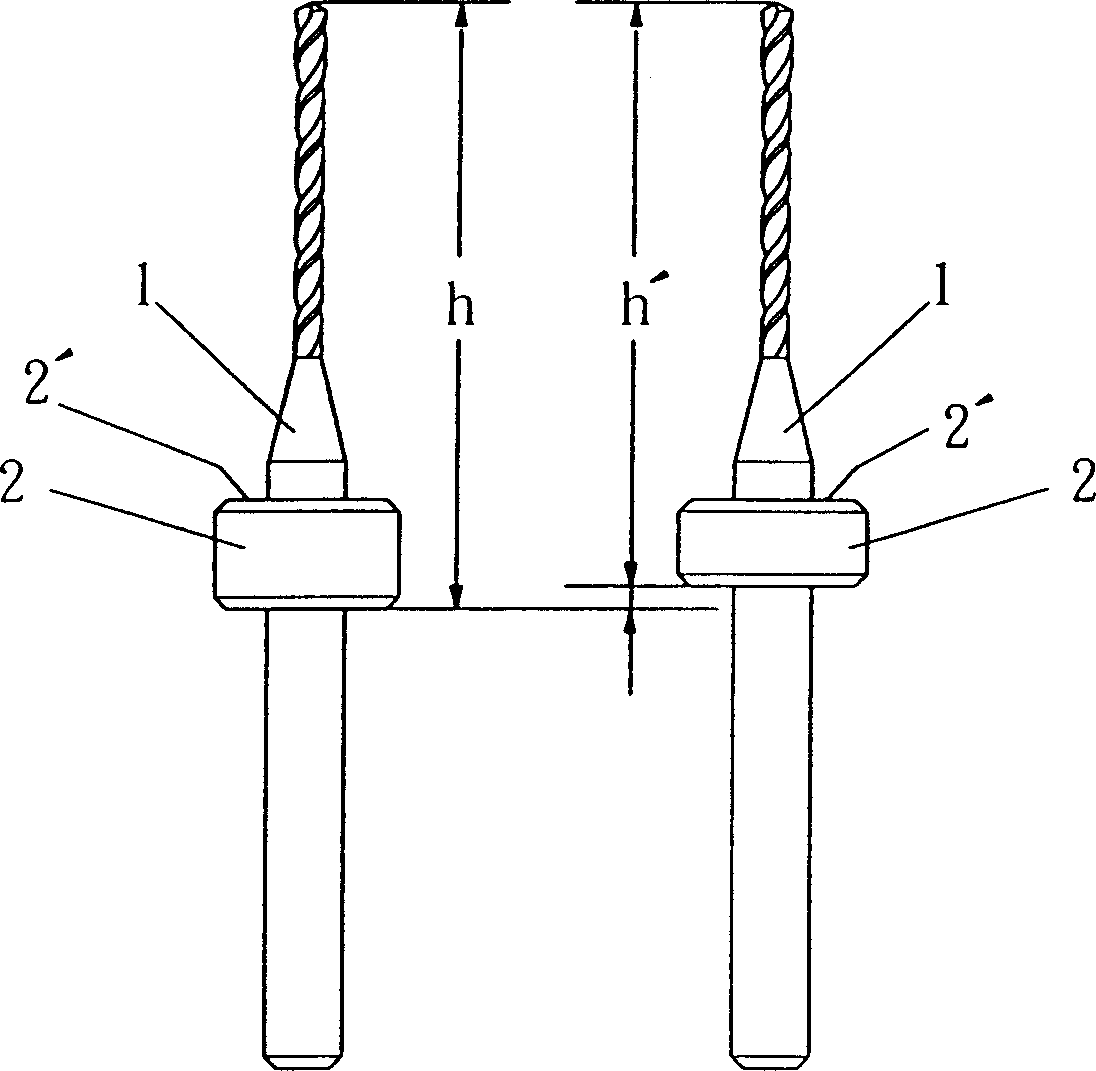

[0027] Referring to Fig. 4, Fig. 5, Fig. 6, and Fig. 7, the first embodiment of the present invention, the method for adjusting, calibrating and positioning the collar of the PC board drill includes the following steps:

[0028] Insert the drill needle 1 sleeved with the collar 2 on the drill stand 10 with the drill edge facing upward; use a side CCD image detector 20 to set a standard height f above the drill stand, and Make the vertical distance from the alignment height f to the top surface 10a of the drill stand equal to the standard upper ring height h of the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com