Surface-mount-type microwave ferrite circulator

A circulator and ferrite technology, applied in the field of surface mount microwave ferrite circulators, can solve the problems of increased production cost, impact on production efficiency, position drift of SMD circulators, etc., and achieves improved welding accuracy and convenient positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

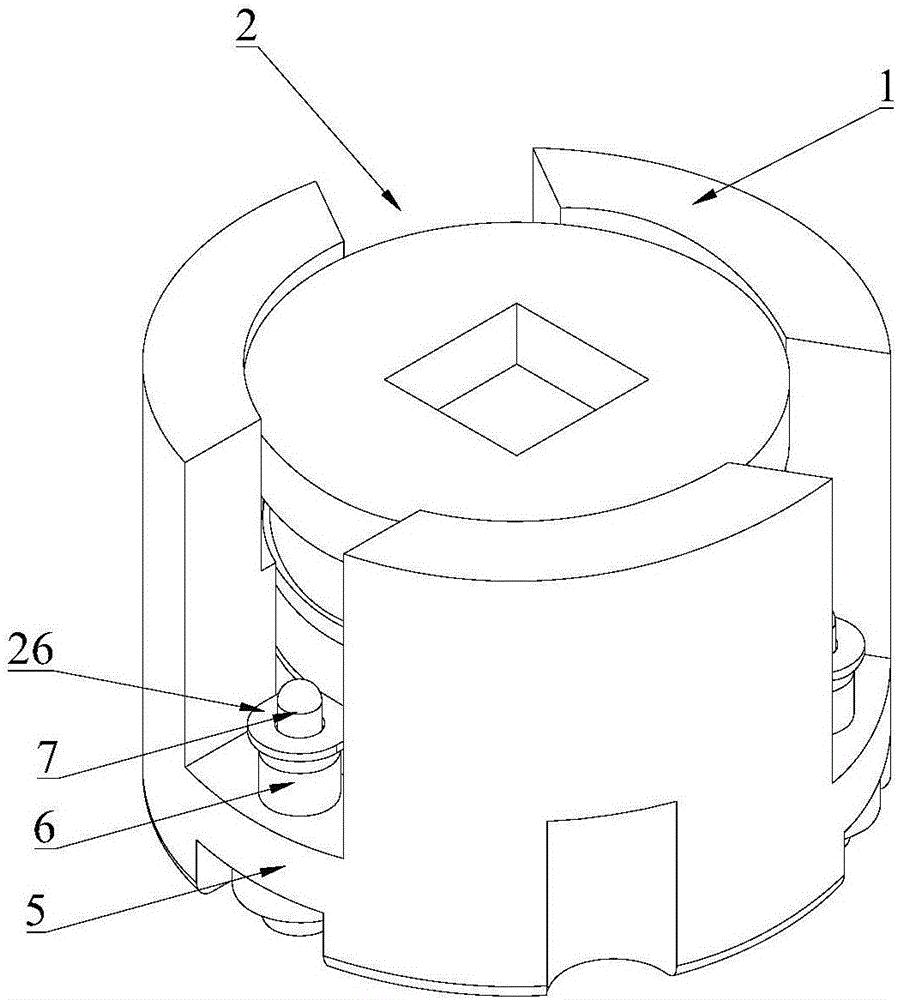

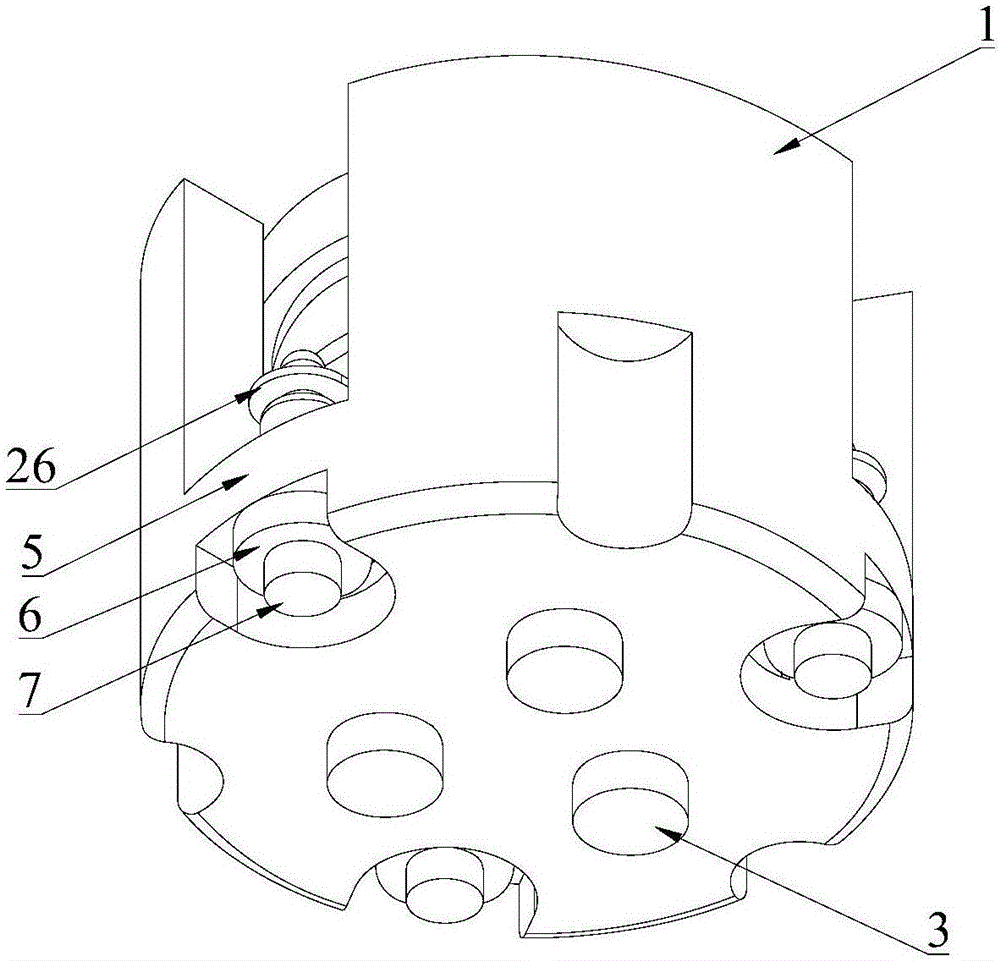

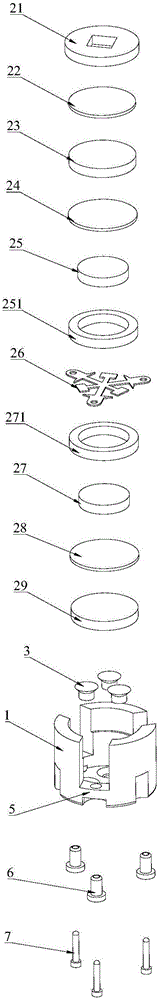

[0031] Please refer to Figure 1 to Figure 3 , Embodiment 1 of the present invention is as follows: figure 1 , figure 2 As shown, a surface-mounted microwave ferrite circulator includes a semi-open cylindrical cavity 1 with three through grooves on the side wall and a stacking part 2 arranged in the cavity. The bottom of the cavity 1 is provided with There is at least one positioning piece 3, the bottom of the cavity 1 is provided with at least one through hole, the positioning piece 3 is arranged in the through hole, the positioning piece 3 protrudes from the bottom surface of the cavity 1, and In this embodiment, three positioning members 3 are provided at the bottom of the cavity 1 , and the three positioning members 3 are uniformly distributed around the central axis of the cavity 1 . Optionally, the positioning member 3 can also be fixed directly on the bottom of the cavity, as long as it can play a positioning role. During welding, the circulator is fixed on the PCB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com