A pin roller type pinion device

A technology of gear devices and rollers, which is applied to transmission devices, friction transmission devices, transmission device parts, etc., can solve the problems of gear loss of rotational motion, ability to reduce load, and degradation of transmission accuracy between gears and racks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

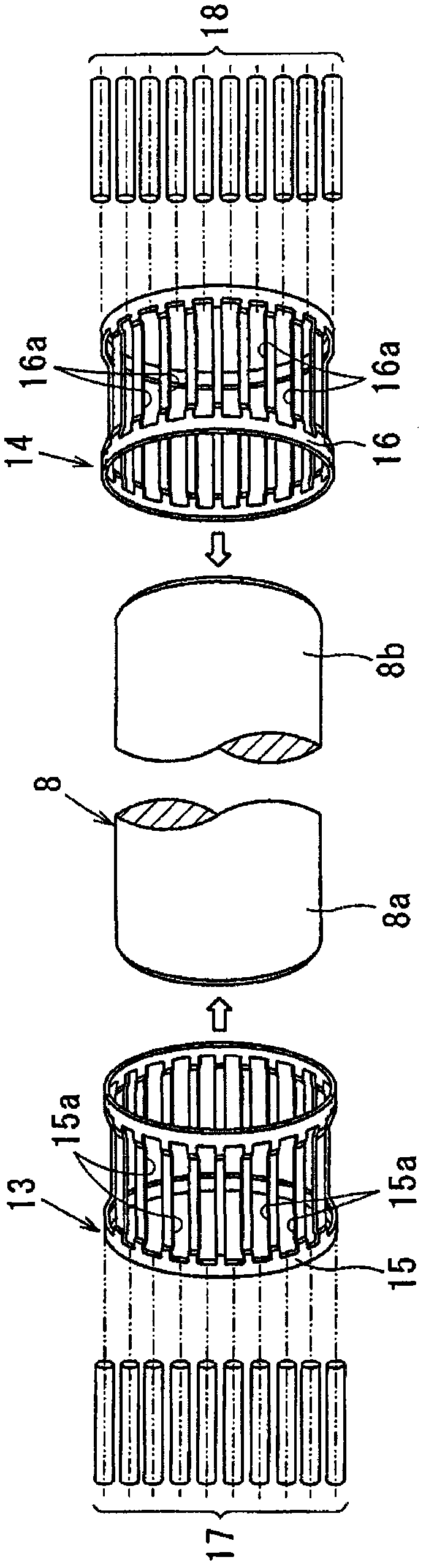

[0039] In the embodiments described in detail below, the same reference numerals are used to represent the same types of technical features, and the positions and directions of different elements are used corresponding to the left, right and upper and lower sides in the drawings of each embodiment of the present invention.

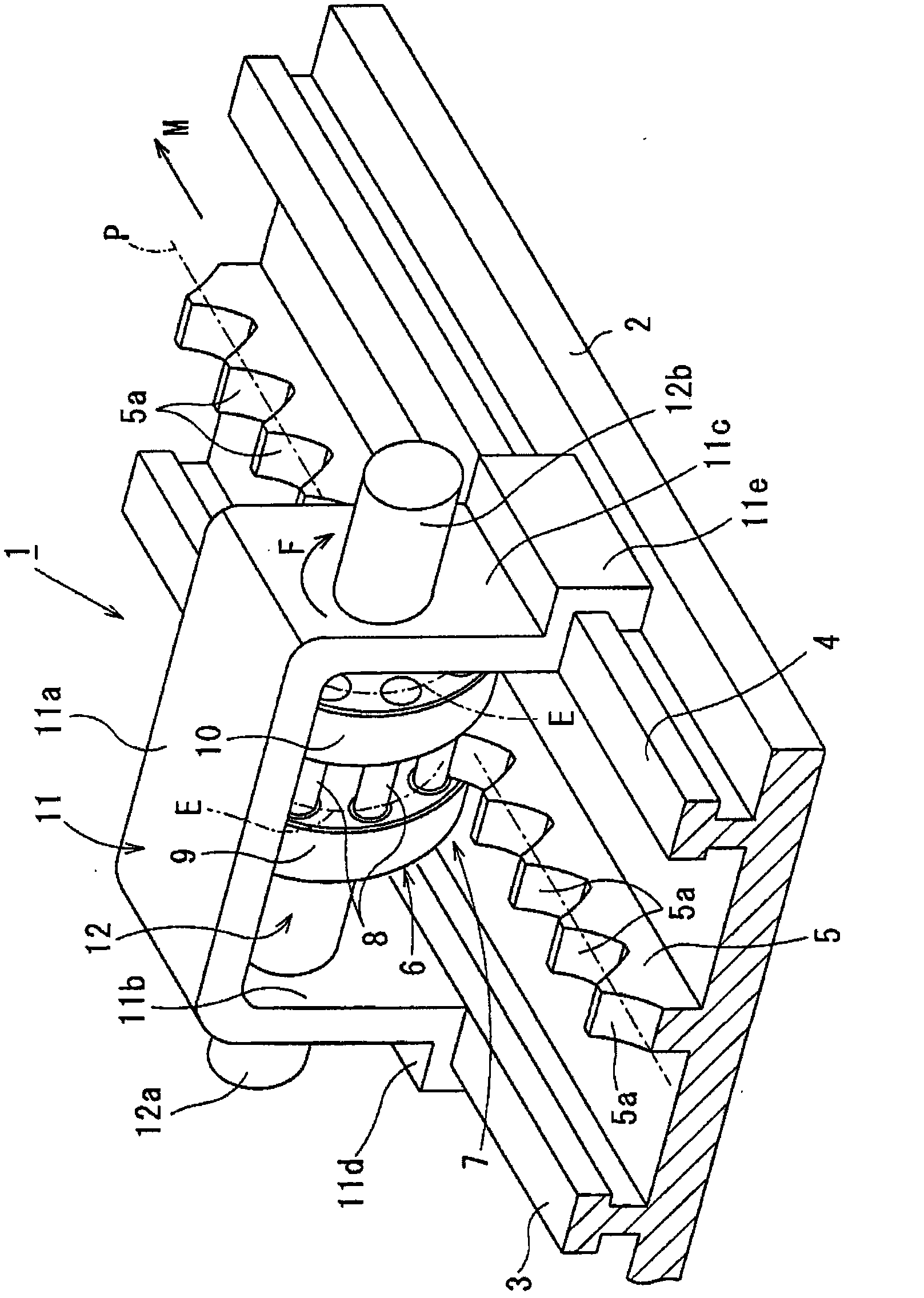

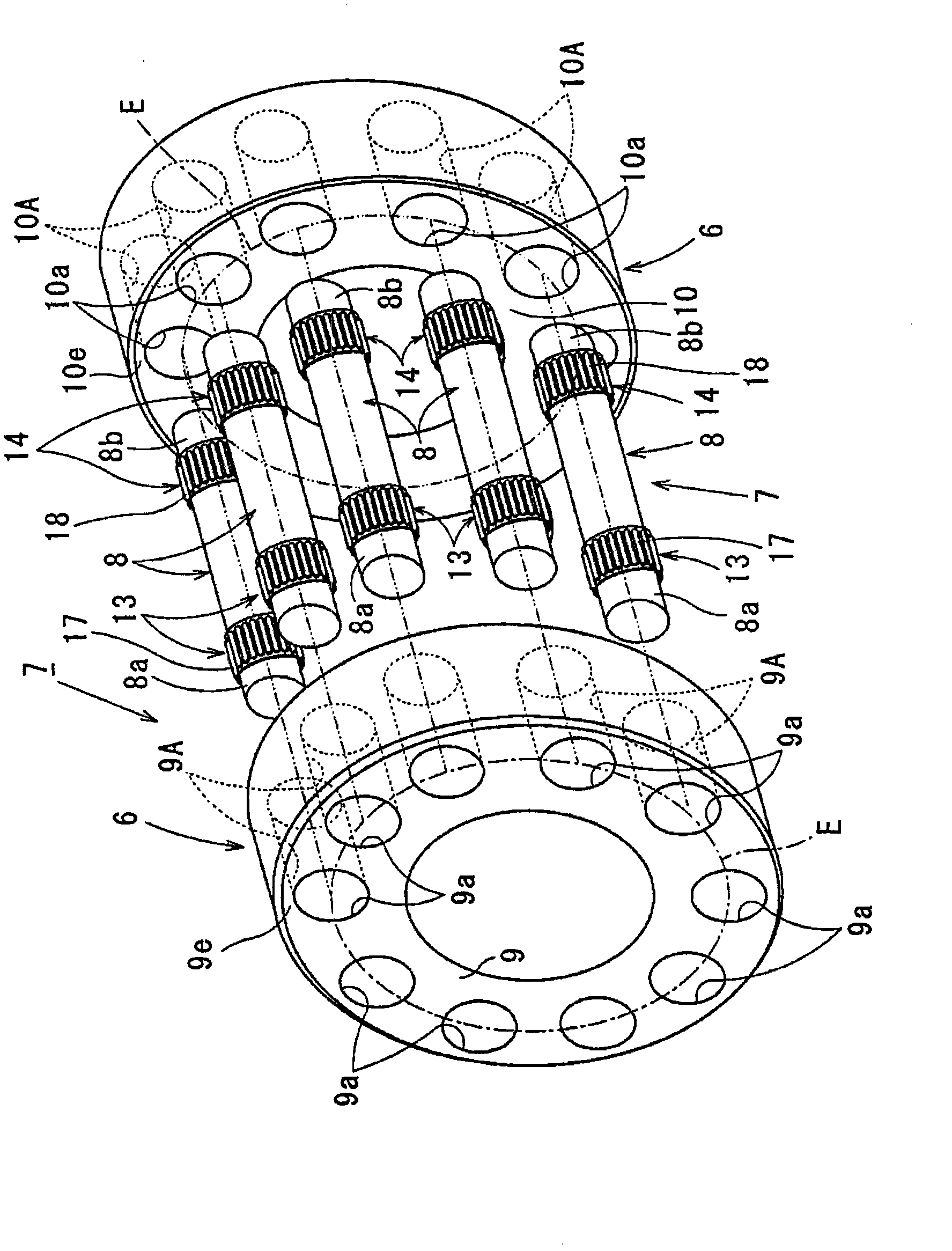

[0040] refer to Figure 1 to Figure 7 , which shows a roller gear device 7 according to a first embodiment of the present invention, as figure 1 Shown, for example, is a rack-and-pinion arrangement 1 with a base plate 2 placed on the floor (not shown) in an assembly plant.

[0041] On the left and right side of the base plate 2 guide rails 3 , 4 are arranged, each guide rail having a T-shaped section. In the middle of the base plate 2 between the guide rails 3, 4, a linear gear 5 is arranged in the longitudinal direction M thereof.

[0042] The length of the rack 5 is determined to satisfy the object used, and the upper surface of the rack 5 has a plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com