Precision spot welder

A spot welding machine and precise technology, applied in welding equipment, soldering irons, tin feeding devices, etc., can solve the problems of broken skeleton, unsmooth solder joints, exposed leads of pins, etc., to achieve compact structure, avoid defects, and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

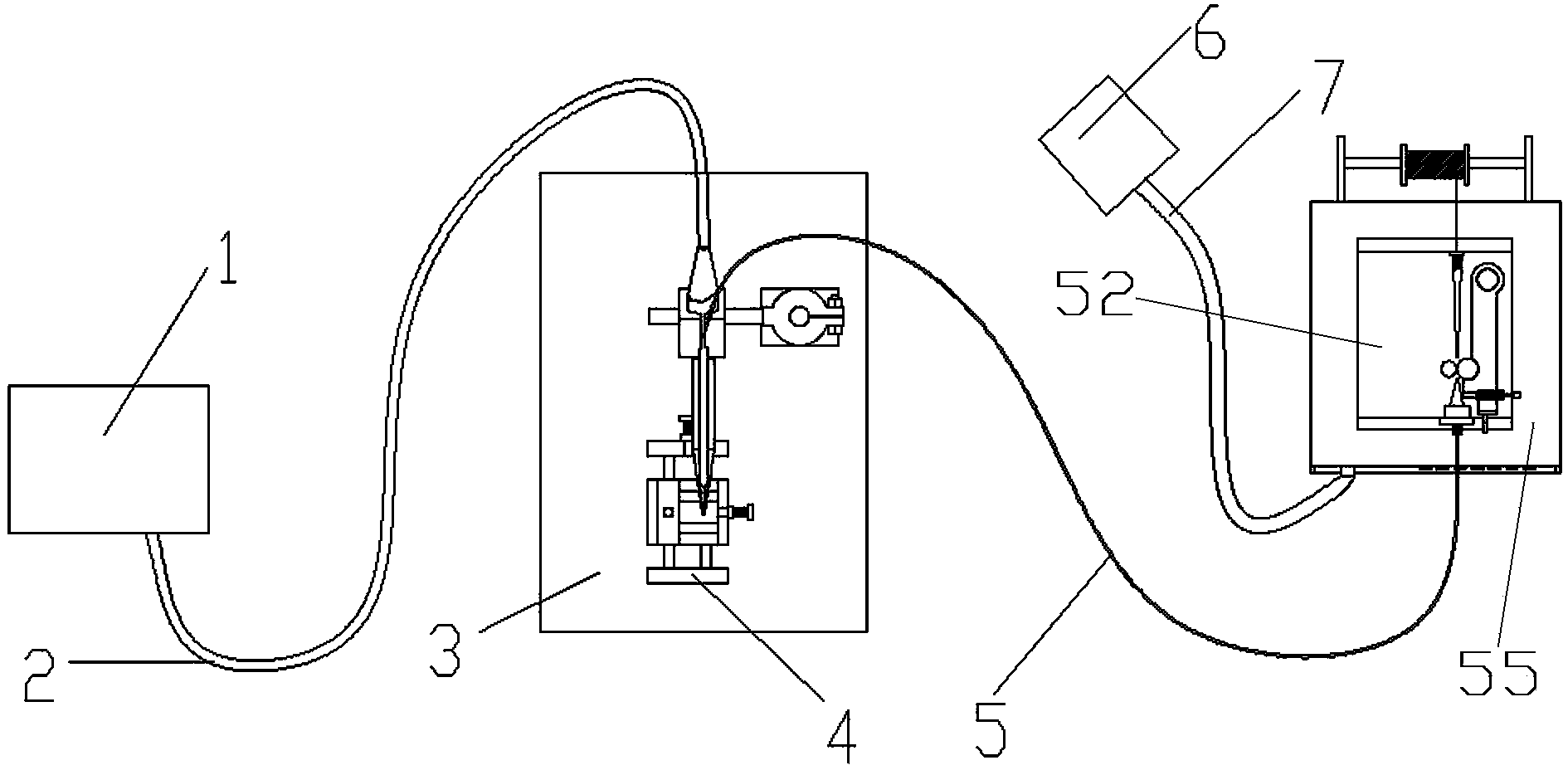

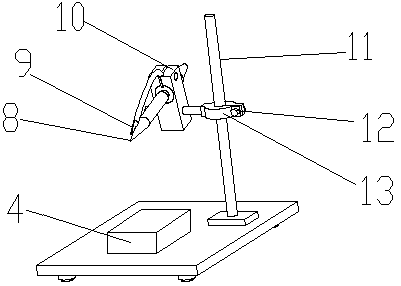

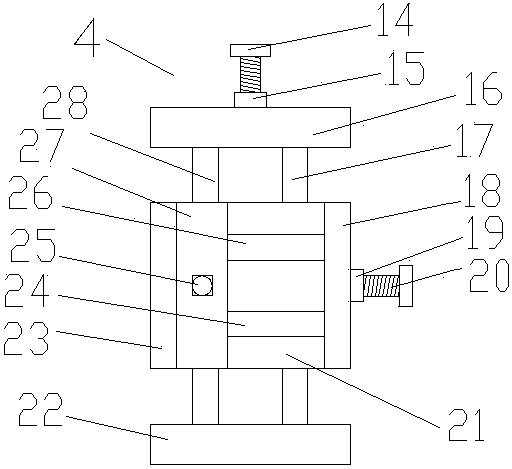

[0021] Refer to attached Figure 1~6 , The precision spot welding machine includes a soldering iron controller, an automatic tin wire device, and a soldering operation device.

[0022] The soldering iron controller has a control box, the control box is equipped with an operation panel, and the operation panel is equipped with a switch 34, a control line interface (soldering iron tip wire interface) 30, a temperature display 29, a temperature setting key 31, a temperature drop key 32, and a temperature increase key 33. A microcomputer controller is installed in the control box. Temperature display 29 adopts commercially available liquid crystal display. Microcomputer controller adopts commercially available microcomputer controller. The soldering iron controller can be purchased, the model is QUICK 203H lead-free intelligent high-frequency welding station.

[0023] The tin wire device that goes out automatically is made of tin wire installation frame 56, tin wire control box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com