Novel fixing bolt for hole

A new type of technology for holes, applied in the direction of bolts, etc., can solve the problems of easy loss, small clamping parts, inconvenient use, etc., and achieve the effect of simple and compact structure, good limit function, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

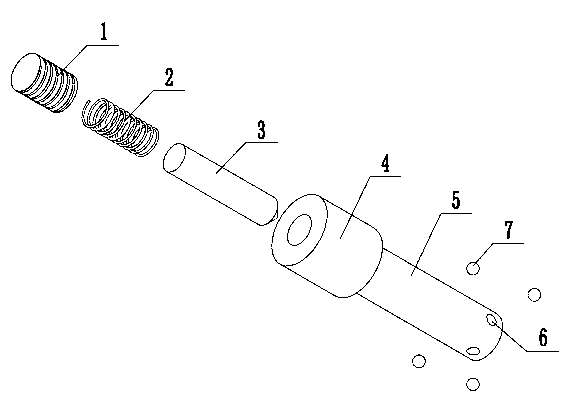

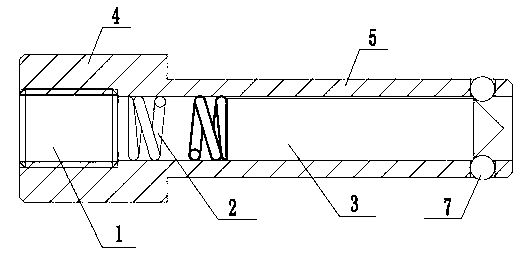

[0014] A new type of fixed pin for holes, including a pin sleeve and a pin 3, the pin sleeve is a T-shaped hollow structure composed of a pin head 4 and a pin rod 5, the pin 3 is a cylinder with a tapered head, and the tapered The structure is conducive to the cooperation with the steel ball. At least one set of symmetrical limit holes 6 are arranged at the end of the pin rod 5. The limit hole and the steel ball are matched to limit the position. The pin 3 is socketed in the pin sleeve, and the length of the pin 3 is Should be less than the length of the pin sleeve, so that the spring can be installed, and the displacement of the pin can be controlled by the spring; the lock nut 1 is screwed in the pin head 4, the spring 2 is set between the lock nut 1 and the pin 3, and the pin 3 is tapped A steel ball 7 is set in cooperation between the shape head and the limiting hole 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com