Ropeless electric connector

An electrical connector, male connector technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve problems such as electric shock accidents, defects in safety performance, unsafety, etc., and achieve the effect of improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

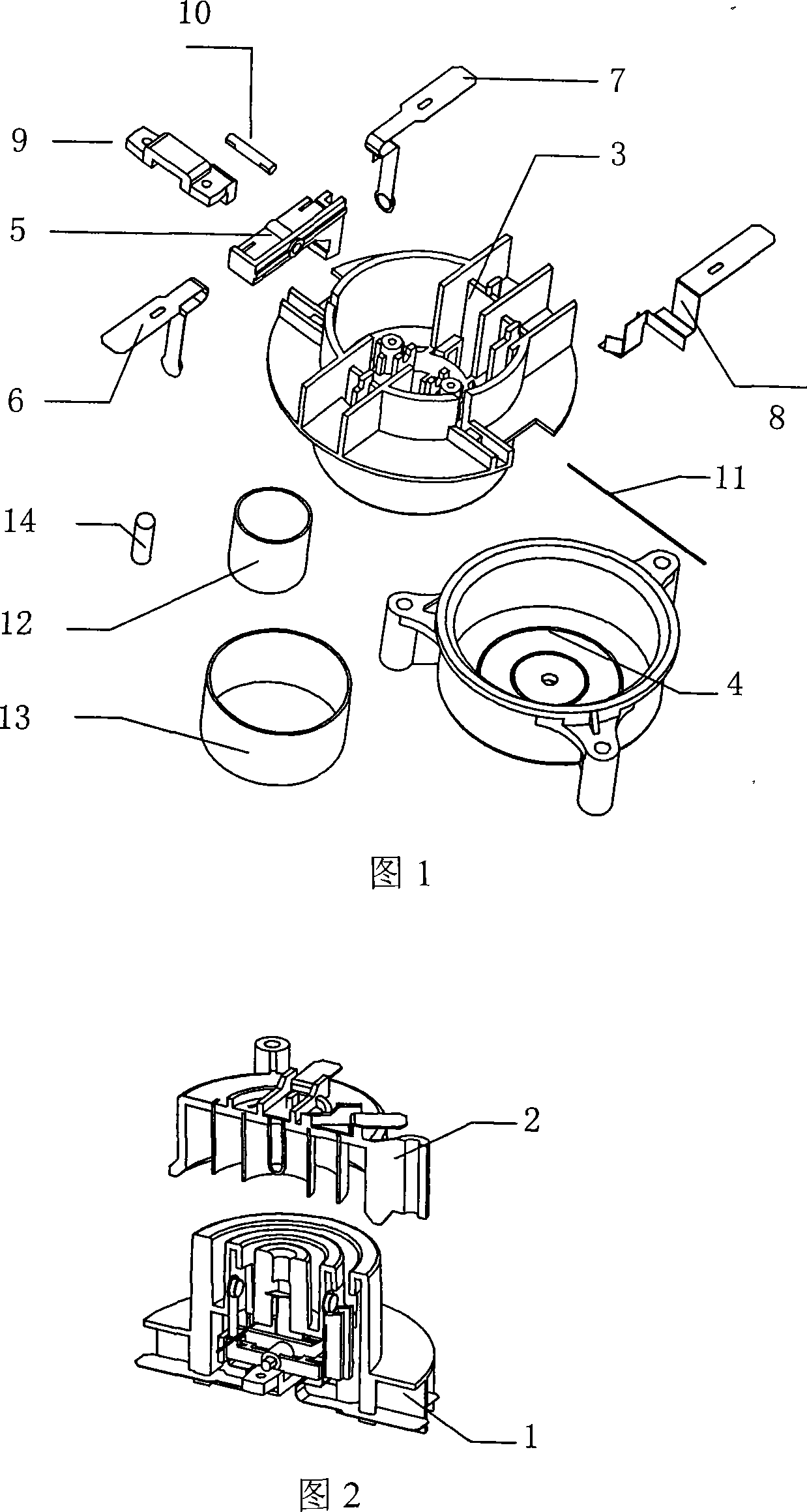

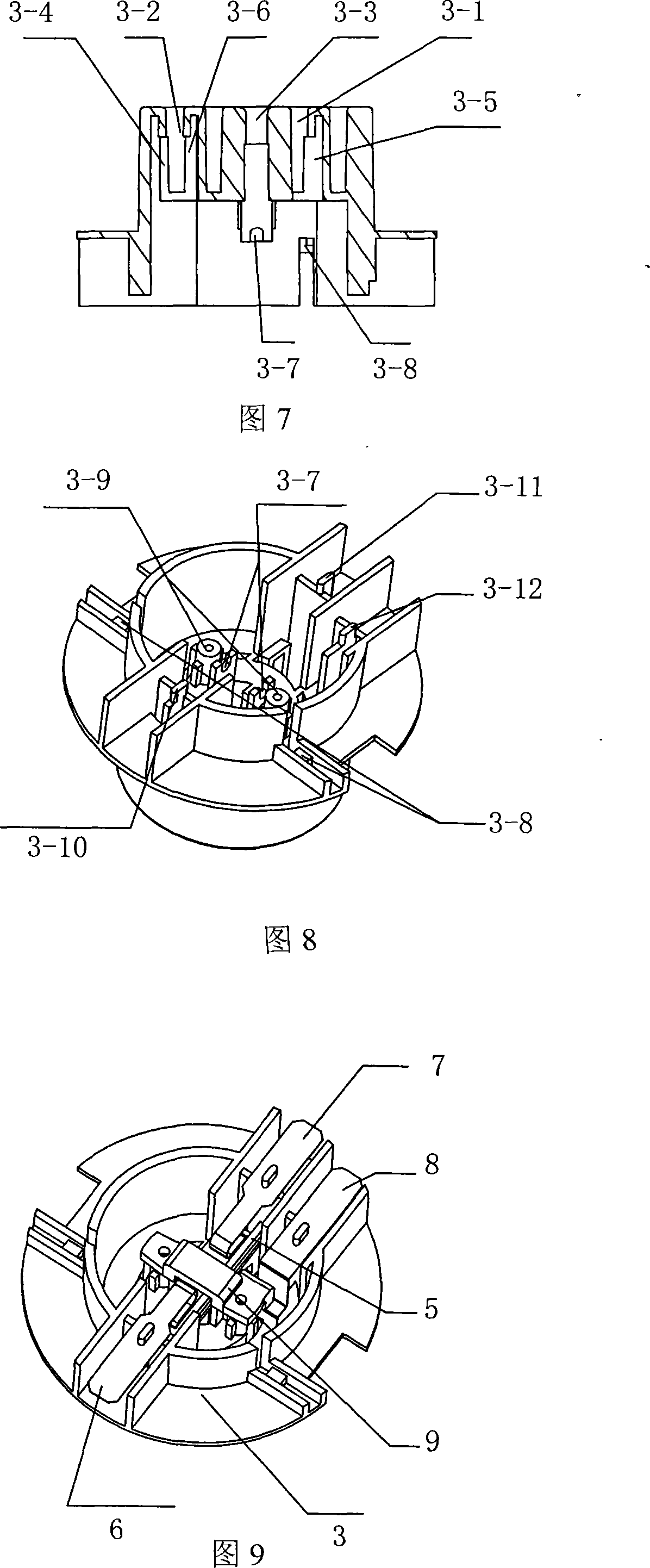

[0036] Fig. 1 is an overall exploded view of the electrical connector, which mainly includes a plastic shell and a conductive circuit. The plastic parts include base 3, cover 4, push pin 5, pin shaft 10, and fixed seat 9. The base 3 and cover 4 form the shell and provide installation positions for other parts. The push pin 5 and pin shaft 10 are transmission parts. , Fixed seat 9 is used for fixing push pin 5. Conductive components include live wire electrical contact piece 6, neutral wire electrical contact piece 7, grounding piece 8, live wire ring 12, neutral wire ring 13, grounding post 14, live wire electrical contact piece 6, neutral line electrical contact piece 7, grounding piece 8 Installed on the base 3 , the live wire ring 12 , the neutral wire ring 13 , and the grounding post 14 are installed on the cover 4 . In addition, a needle spring 1...

Embodiment 2

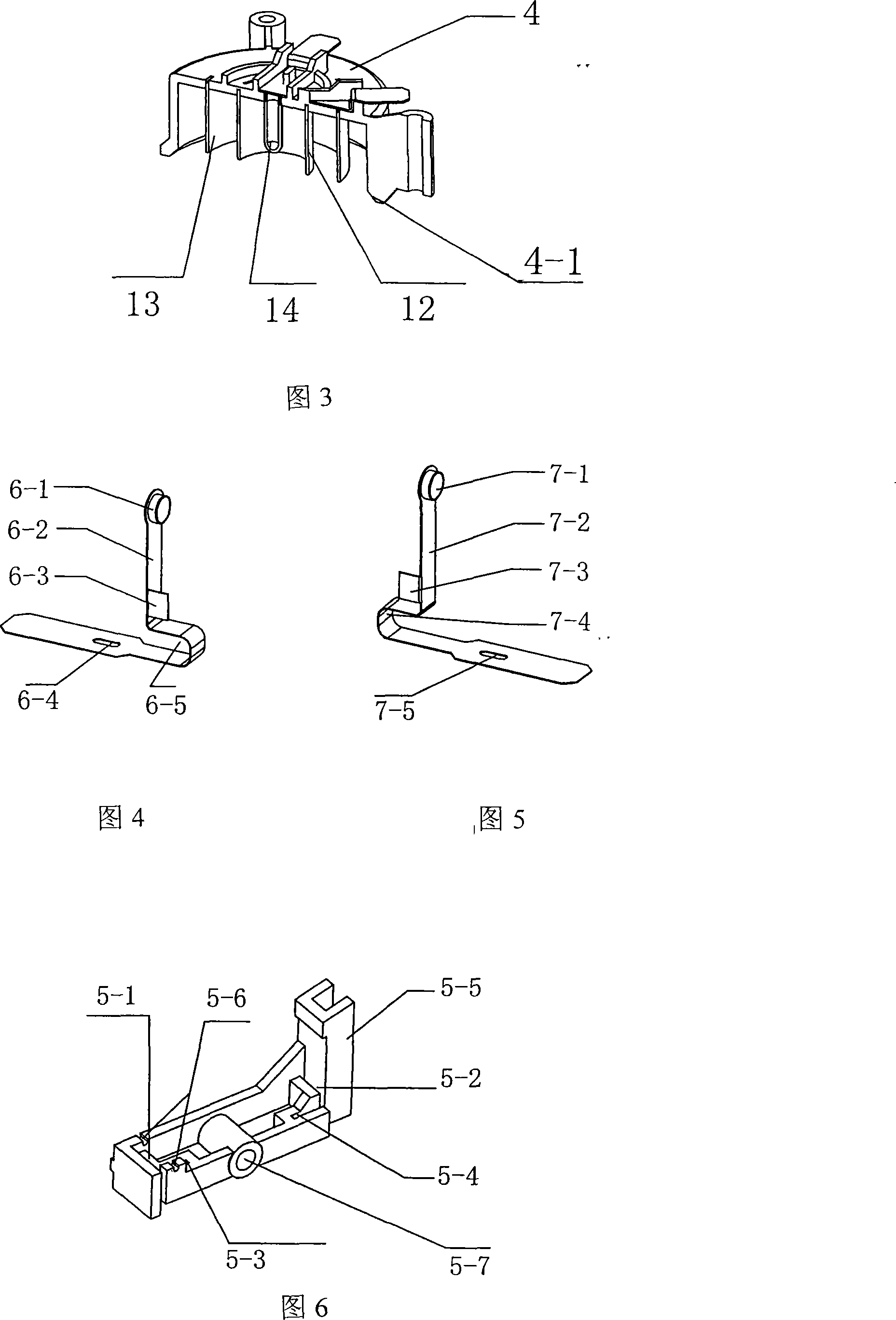

[0046] Embodiment 1 adopts a lever mechanism, and the offset of the electric contact piece 6 of the live line and the electric contact piece 7 of the neutral line is realized through the rotation of the lever. Embodiment 2, which is described in detail next, converts the movement of the cover 4 in the vertical direction into the movement of the push pin 5' in the horizontal direction through the inclined mechanism, and the push pin 5' further drives the electric contact piece 6 of the live line and the electric contact piece of the neutral line. 7 is offset, so that the electrical contacts 6-1, 7-1 on it press the live wire ring 12 and the neutral wire ring 13 respectively, thereby connecting the circuit.

[0047] FIG. 3 is a half-section structure diagram of the male connector 2 in the electrical connector. The lower edge of the cover 4 has a circular downward pressing slope 4-1.

[0048] Fig. 13 is an oblique view of the push pin 5' in the electrical connector. Compared with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com