Rotating torsion conveyer

A transmitter and torque technology, applied in the field of bar-shaped rotary torque transmitter, can solve the problems of poor adaptability and single function, and achieve the effects of simple manufacture, wide application and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

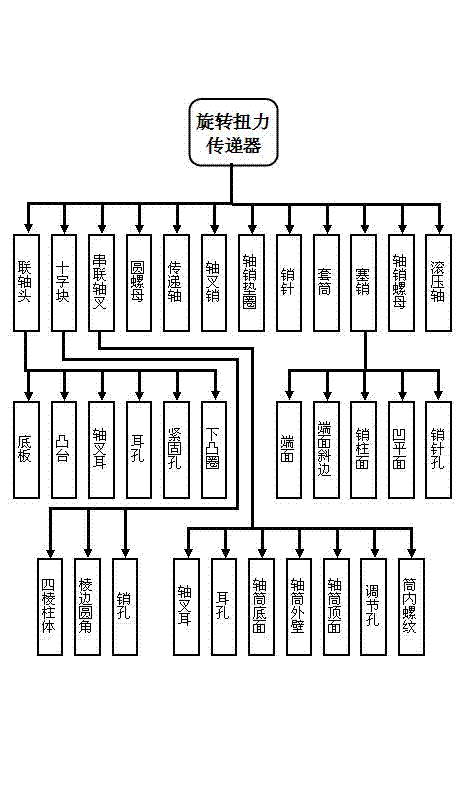

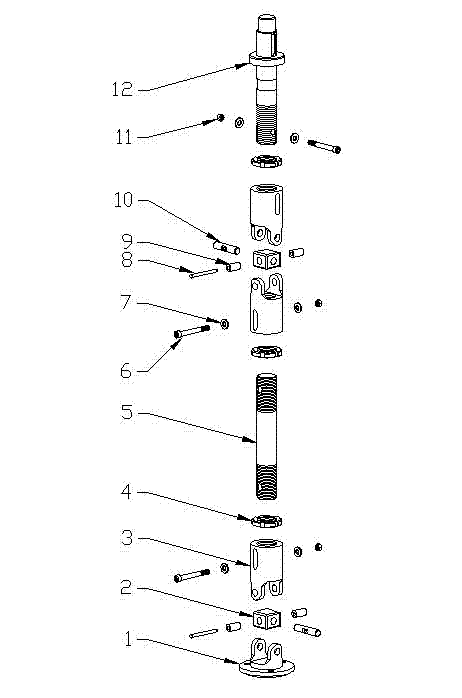

[0031] As a product technical proposal, the present invention can be implemented through the organic combination of related parts. The organizational structure of the product of the present invention is as figure 1 shown.

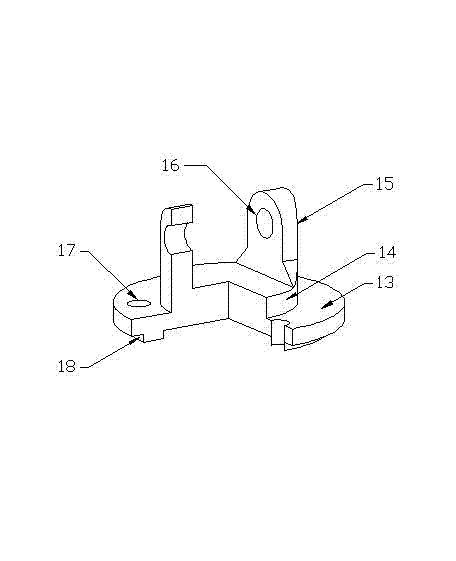

[0032] figure 1 Among them, the product of the present invention consists of eleven parts including coupling head, cross block, series shaft fork, round nut, transmission shaft, shaft fork pin, shaft pin washer, pin, sleeve, plug pin, shaft pin nut, and rolling shaft Composition; Among them, the coupling head parts include six parts: base plate, boss, shaft fork lug, ear hole, fastening hole, and lower convex ring, and the cross block part includes three parts: quadrangular prism, edge fillet, and pin hole Parts, series shaft fork parts include shaft fork lugs, ear holes, bottom surface of the shaft cylinder, outer wall of the shaft cylinder, top surface of the shaft cylinder, adjustment hole, and internal thread of the cylinder. Cylinder, concave plane,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com