Manufacturing method of HDI circuit board

A production method and circuit board technology, which are applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit and other directions, can solve the problems of large knife wear and long working hours, and achieve the effect of reducing production cost and shortening production period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

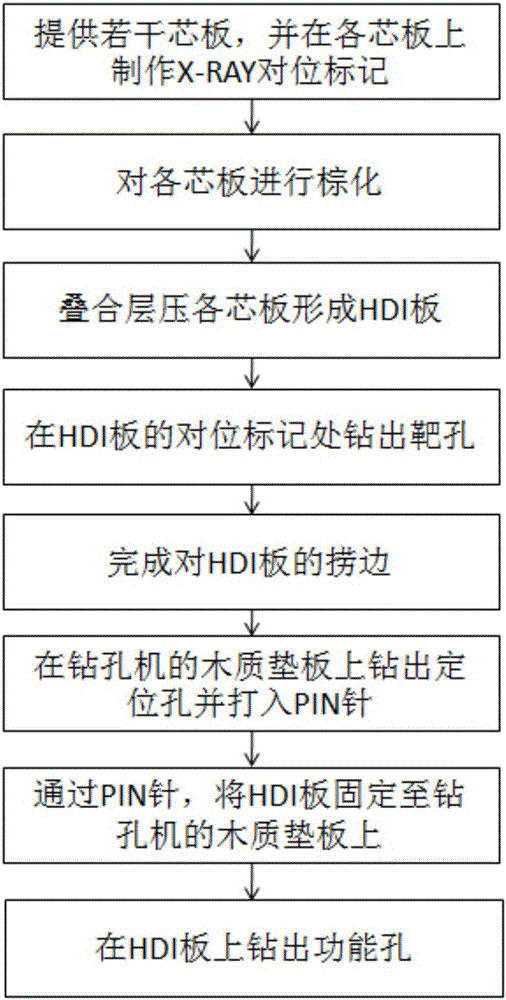

[0025] Such as figure 2 , the manufacture method of a kind of HDI circuit board of the present invention, comprises the steps:

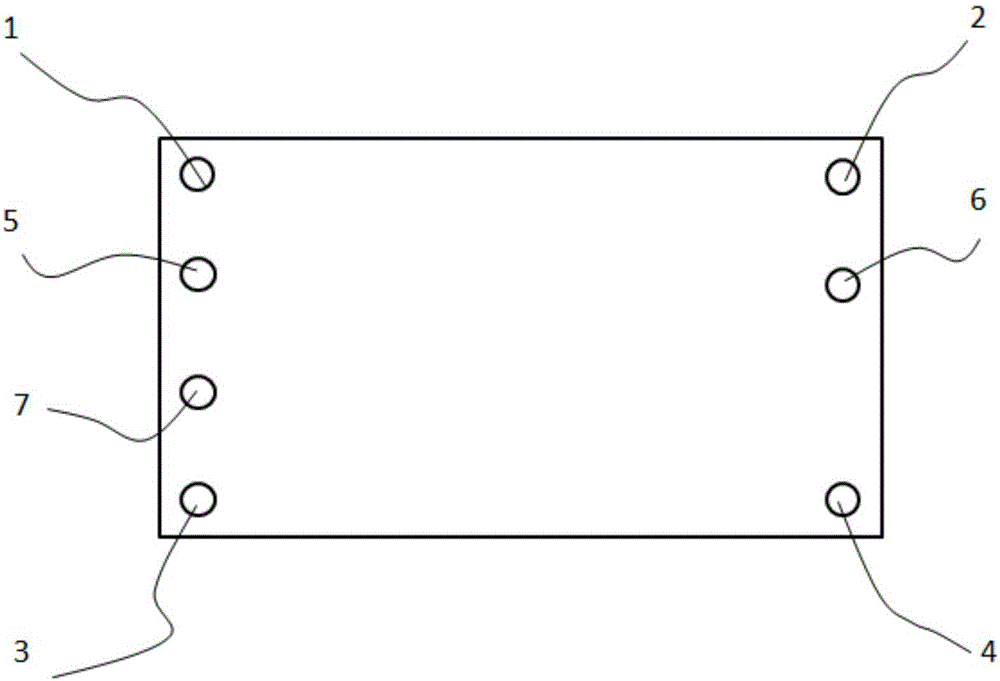

[0026] Step 1: Provide several core boards, and set X-RAY alignment marks on the upper surface of each core board. In this embodiment, each core board is a rectangular core board with copper foil on its surface, and the alignment marks are evenly distributed on the four corners of the core board.

[0027] Step 2: Browning each core board, that is, roughening the smooth copper foil layer on the upper and lower surfaces of the core board, so as to enhance the bonding force of the core board in the subsequent lamination and lamination process.

[0028] Step 3: The core boards are stacked and laminated in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com