LED (Light Emitting Diode) display screen module with separated lamp boards and driving boards

A separation technology of LED display and lamp driver, applied in static indicators, instruments, etc., to improve the service life, enhance the heat dissipation effect, and reduce the consumption time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, structure and working process of the present invention will be further described.

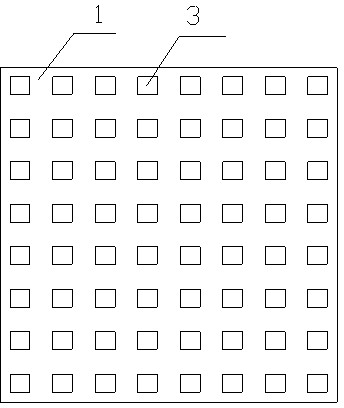

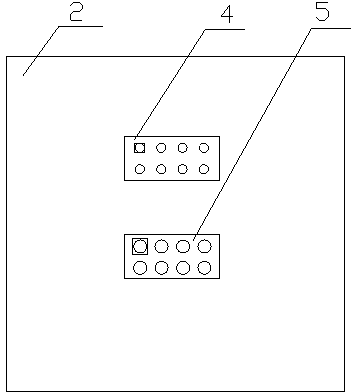

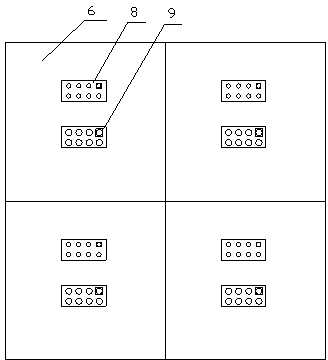

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an LED display module with separate lamp drive includes a circuit board, and the circuit board includes LED lamp boards and drive boards that are mutually matched and connected. The LED lamp boards and drive boards are in multiple groups, and each group A number of LED lamps 3 are evenly arranged on the front side 1 of the middle LED light board, and the first signal interface 4 and the first power supply interface 5 are arranged on the back side 2 of the LED light board, and the second signal interface 8, the second Power supply interface 9, LED light driver IC10, signal input port 11, signal output port 13, power supply input port 12 are arranged on the back side 7 of the driving board, the first signal interface 4 is connected with the second signal interface 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com