Preparation method for porous carbon material with high specific surface area

A high specific surface area, porous carbon technology, applied in the field of preparation methods, can solve the problems of unsafe ecological environment, residues, poor digestion and absorption of tetracycline, etc., and achieve the simple and easy preparation method, easy control of operation, and fast adsorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

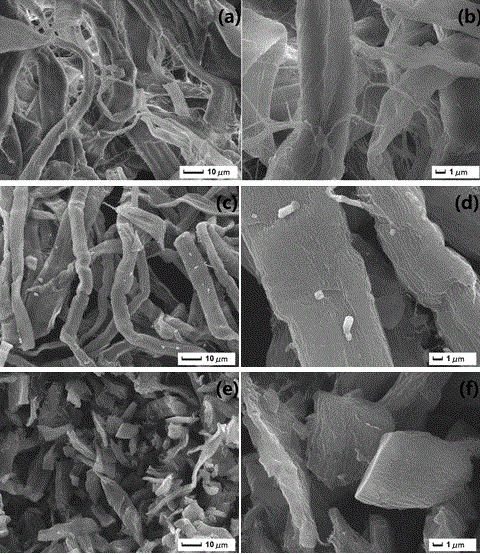

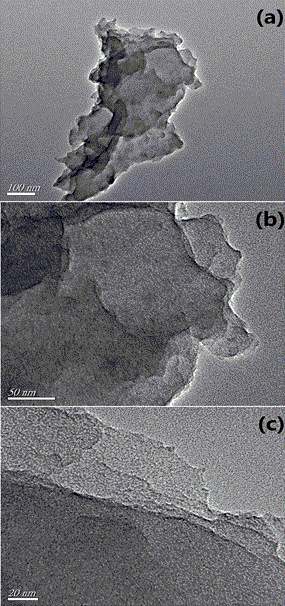

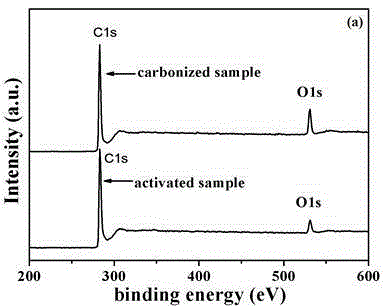

[0028] Add 10g of waste paper towels into the porcelain boat and carbonize in a tube furnace at a carbonization temperature of 500°C and a heating rate of 5°C / min for 2 hours; mix and grind the carbide and potassium hydroxide at a mass ratio of 1:4 to make a uniform, Put it into a nickel pot and activate it in a tube furnace, the activation temperature is 850°C, the heating rate is 5°C / min, and it is maintained for 1h. Soak the activated product with hydrochloric acid to remove impurities, vacuum filter, wash with water until neutral, and dry the existing porous carbon material.

Embodiment 2

[0030] Add 10g of waste paper towels into the porcelain boat and carbonize in a tube furnace at a carbonization temperature of 500°C and a heating rate of 5°C / min for 2 hours; mix and grind an appropriate amount of carbide and potassium hydroxide at a mass ratio of 1:4 , placed in a nickel pot and activated in a tube furnace, the activation temperature was 800°C, the heating rate was 5°C / min, and maintained for 1h. Soak the activated product with hydrochloric acid to remove impurities, vacuum filter, wash with water until neutral, and dry the existing porous carbon material.

Embodiment 3

[0032] Put 10g of waste paper towels into the porcelain boat and carbonize in a tube furnace at a carbonization temperature of 500°C and a heating rate of 5°C / min for 2 hours; add an appropriate amount of carbide and potassium hydroxide at a mass ratio of 1:x(x= 0, 1, 2, 3) Mix and grind evenly, put into a nickel pot and activate in a tube furnace, the activation temperature is 850°C, the heating rate is 5°C / min, and maintain for 1h. Soak the activated product with hydrochloric acid to remove impurities, vacuum filter, wash with water until neutral, and dry the existing porous carbon material.

[0033] The adsorption capacity and specific surface area of tetracycline prepared by the porous carbon prepared under different parameters are listed in Table 1 in detail.

[0034] 2, the present invention will be further described below in conjunction with specific implementation examples:

[0035] In the specific embodiment of the present invention, the adsorption performance eval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com