Method for preparing special fracturing propping agent for shale gas by utilizing low-carbon coal gangue

A fracturing proppant and coal gangue technology, which is applied in the fields of earthwork drilling, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of low-density high-strength fracturing proppant, low thermal efficiency, and high heat loss , to achieve the effect of shortening the sintering cycle, increasing the product yield and reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

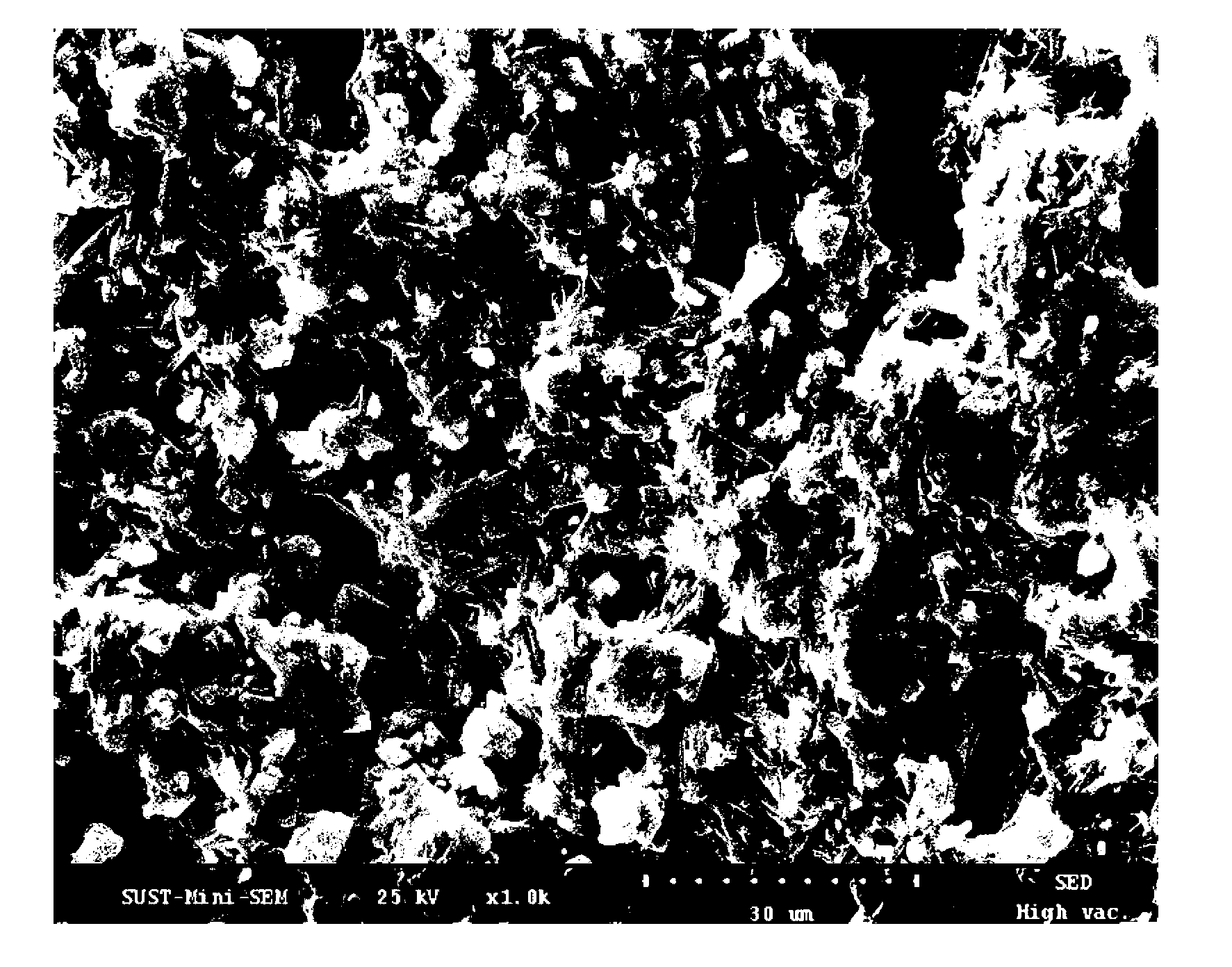

Image

Examples

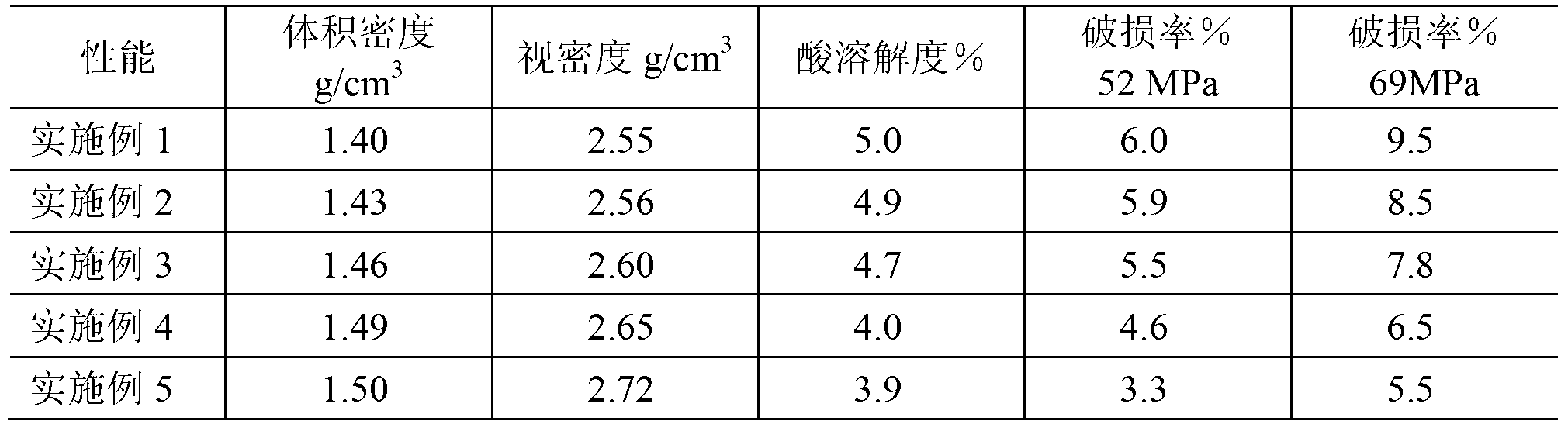

Embodiment 1

[0030] 1) Put the low-carbon coal gangue into a ball mill and use alumina balls as balls for dry grinding for 0.5h, and then pass through a 120-mesh sieve to obtain coal gangue powder. Mesh sieve, collect the sieve residue particles between the two sieves to become coal gangue masterbatch; put industrial coke into a ball mill and use alumina balls as balls for dry grinding for 0.5h, and then pass through a 180 mesh sieve to obtain coke powder; Among them, when dry grinding low-carbon coal gangue, control the mass ratio of alumina ball stone and low-carbon coal gangue to 3:1, and when dry grinding industrial coke, control the mass ratio of alumina ball stone and industrial coke to 3:1;

[0031] 2) According to the mass percentage, mix 68% coal gangue powder, 25% manganese slag, 6.5% silicon micropowder, and 0.5% industrial coke to obtain a mixture; then put the mixture into a ball mill to obtain alumina ball stone Add water to the balls and mix for 0.5 hours to form a mixed slu...

Embodiment 2

[0038] 1) Put the low-carbon coal gangue into a ball mill and use alumina balls as balls for dry grinding for 0.8h, and then pass through a 120-mesh sieve to obtain coal-gangue powder. Mesh sieve, collect the sieve residue particles between the two sieves to become coal gangue masterbatch; put industrial coke into a ball mill and use alumina balls as balls for dry grinding for 0.8h, and then pass through a 180 mesh sieve to obtain coke powder; Among them, when dry grinding low-carbon coal gangue, control the mass ratio of alumina ball stone and low-carbon coal gangue to 2.8:1, and when dry grinding industrial coke, control the mass ratio of alumina ball stone and industrial coke to 2.8:1;

[0039] 2) According to the mass percentage, mix 70% of coal gangue powder, 22% of manganese slag, 7.3% of silicon micropowder, and 0.7% of industrial coke to obtain a mixture; then put the mixture into a ball mill to form alumina balls Add water to the grinding balls and wet grind for 1 hou...

Embodiment 3

[0045] 1) Put the low-carbon coal gangue into a ball mill and use alumina balls as balls for dry grinding for 1 hour, then pass through a 120-mesh sieve to obtain coal gangue powder, and pass the low-carbon coal gangue that has not passed the 120-mesh sieve through 48-70 mesh Sieve, collect the sieve residue particles between the two sieves to become coal gangue masterbatch; put industrial coke into a ball mill and use alumina ball stone as a ball for dry grinding for 1 hour, and then pass through a 180-mesh sieve to obtain coke powder; among them, When dry grinding low-carbon coal gangue, control the mass ratio of alumina ball stone and low-carbon coal gangue to 2.5:1, and when dry grinding industrial coke, control the mass ratio of alumina ball stone and industrial coke to 2.5:1;

[0046] 2) According to the mass percentage, mix 73% of coal gangue powder, 16.1% of manganese slag, 10% of silicon micropowder, and 0.9% of industrial coke to obtain a mixture; then put the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com