Method for producing light-weight heat-insulating decorative ceramic plate by using solid waste in production and processing course of expanded pearlite

A technology for expanding perlite and solid waste, which is applied in the production and application of ceramic products and ceramic materials, and can solve the problems of extremely poor surface wear resistance and erosion resistance, high water absorption, and low flexural strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

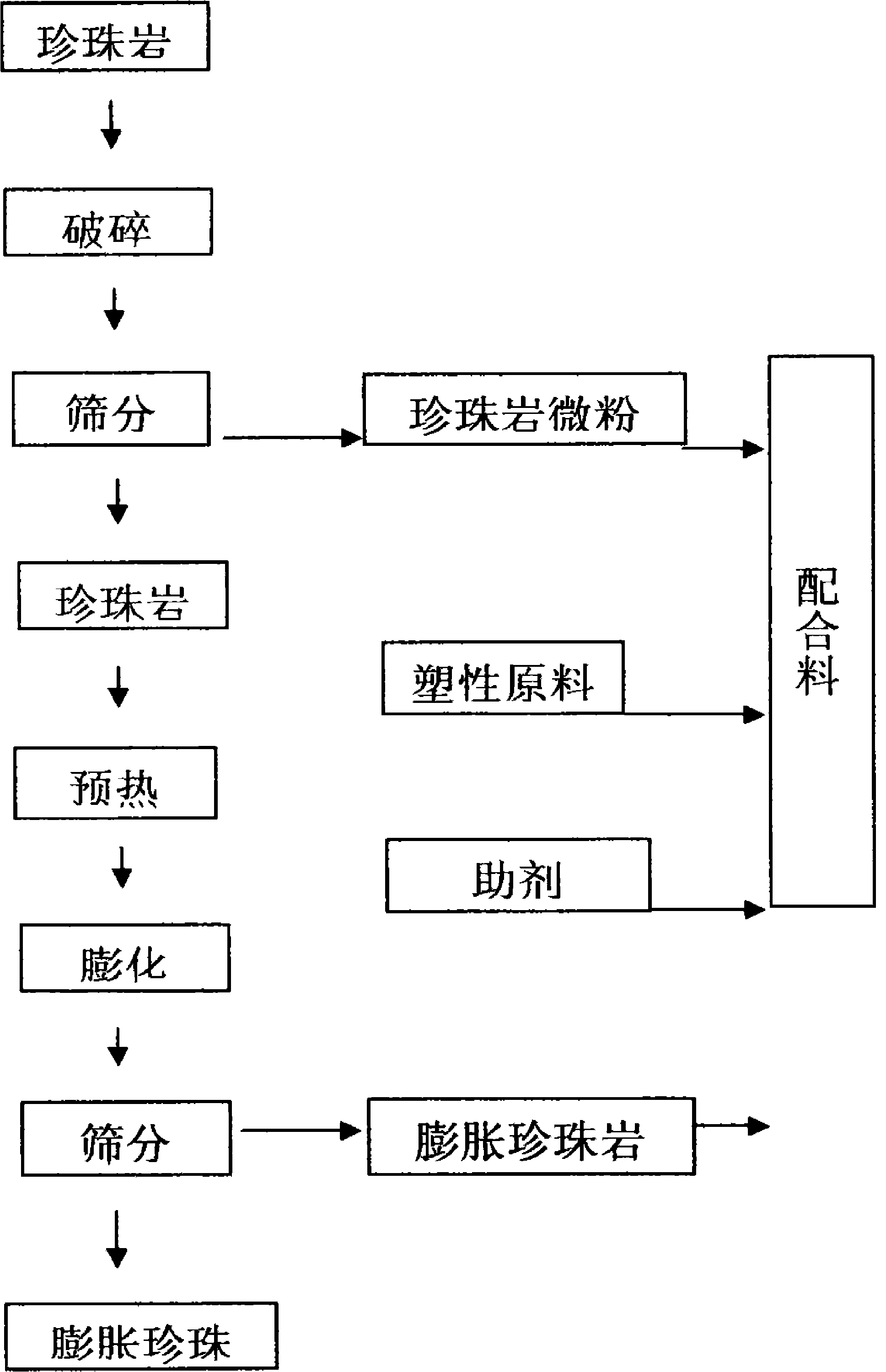

Method used

Image

Examples

Embodiment 1

[0040] Mix by weight 66% of perlite micropowder, 20% by weight of expanded perlite micropowder, 10% by weight of bentonite, 2% by weight of limestone, 2% by weight of fluorite powder, 0.8% by weight of nonahydrate silica, 0.8% by weight Black silicon carbide, 0.2% by weight of sodium humate, 101.8% by weight of mineral raw materials are put into the aluminum-lined ball mill, and 55% by weight of water is added for wet ball milling. Among them, the fineness of the mud is controlled between 0.6-1% of the sieve of the million-hole sieve, the flow rate of the mud is controlled between 25-45 seconds of the coating four viscosity; More than 65% on the 60-mesh sieve, less than 30% on the 80-mesh sieve under the 60-mesh sieve, and less than 5% under the 80-mesh sieve; the moisture content of the powder is controlled between 6.5-7.5%; the dry strength of the green body is controlled at 0.95-1.2MPA. According to the above process system, after ball milling of raw materials, sieving of m...

Embodiment 2

[0042]Mix by weight 88% perlite micropowder, weight 8% bentonite, weight 2% limestone, weight 2% fluorite powder, weight 0.8% black silicon carbide, weight 1% sodium metasilicate, weight 0.6% Fluorite, 0.1% by weight of green body reinforcing agent, 0.2% by weight of sodium humate, and 0.1% by weight of sodium tripolyphosphate composed of 102.8% of the mineral raw materials are put into the aluminum-lined ball mill and 55% by weight of Water wet ball milling. Among them, the fineness of the mud is controlled between 0.6-1% of the sieve of the million-hole sieve, the flow rate of the mud is controlled between 25-45 seconds of the coating four viscosity; More than 65% on the 60-mesh sieve, less than 30% on the 80-mesh sieve under the 60-mesh sieve, and less than 5% under the 80-mesh sieve; the moisture content of the powder is controlled between 6.5-7.5%; the dry strength of the green body is controlled at 0.95-1.2MPA. According to the above process system, the water absorption...

Embodiment 3

[0044] Mix by weight 55% perlite fine powder, weight 24% expanded perlite fine powder, weight 12% black mud, weight 3% bentonite, weight 2% calcium carbonate, weight 4% fluorite, weight 0.2% Sodium humate, 0.1% by weight of sodium tripolyphosphate, 0.8% by weight of sodium metasilicate, and 0.12% by weight of reinforcing agent are composed of 101.1% of mineral raw materials by weight, which are put into a high-white and high-alumina liner inlaid ball mill for wet grinding , the ball stone is also high white high alumina ball stone. The water absorption rate is 0.25% and the bulk density is 442kg / m 3、 The modulus of rupture is 10.8MPa, the thermal conductivity is 0.076W / (m.k), and the combustion level is A1, which is an integrated ceramic plate for thermal insulation and decoration.

[0045] application notes

[0046] The invention relates to the technical field of heat preservation and decoration materials, especially the thermal conductivity produced by using the solid wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com