Ultralow-temperature low-deformation glazed green brick body and preparation method thereof

A glazed tile, low deformation technology, applied in the field of building ceramic materials, can solve problems such as difficulty in guaranteeing product performance indicators, sustainable development constraints, and shortening the firing temperature range, so as to promote sustainable development and facilitate industrialization Promotion and application, the effect of expanding the sintering temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

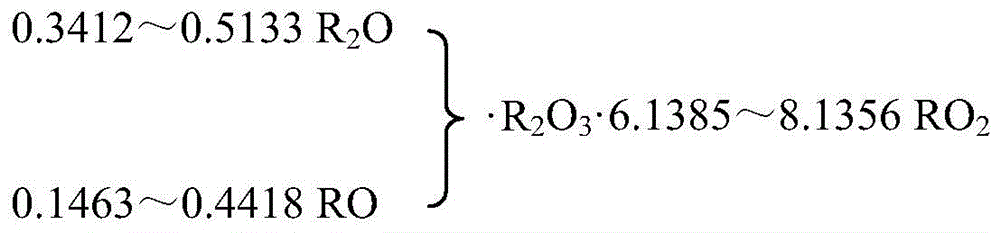

Method used

Image

Examples

Embodiment Construction

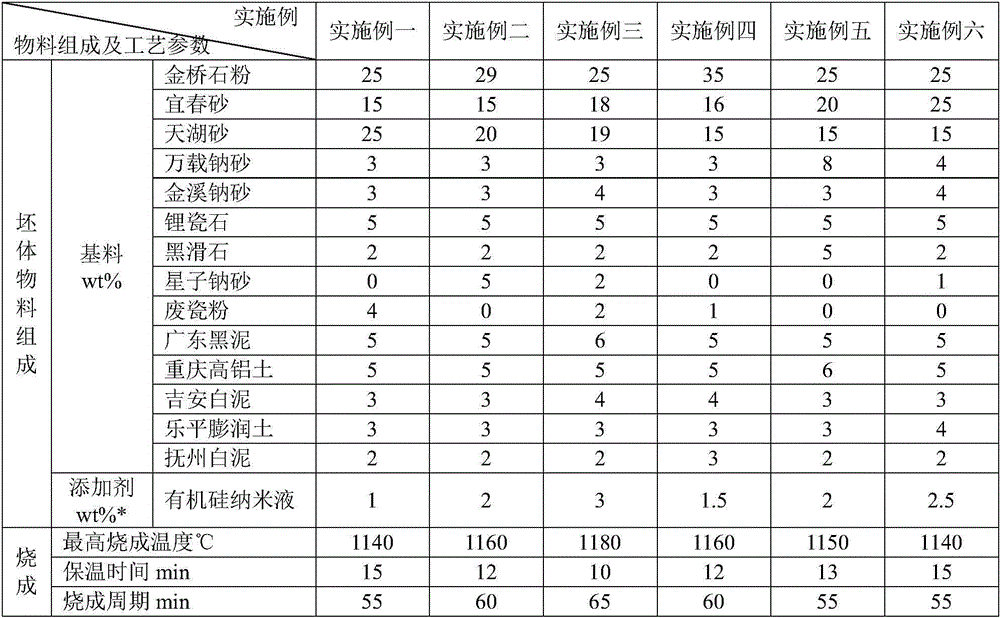

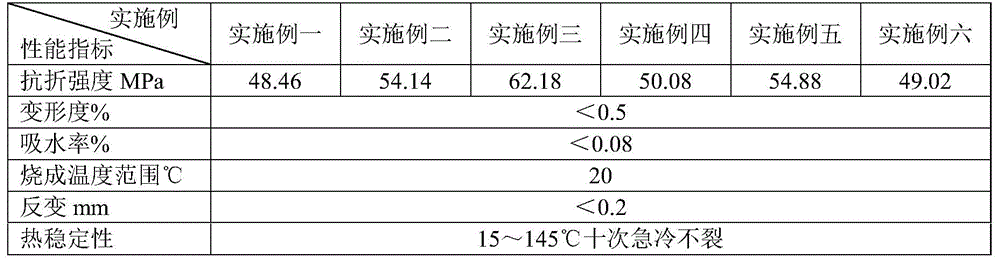

[0022] The material composition of an ultra-low temperature and low deformation polished glazed brick body in the embodiment of the present invention is shown in Table 1.

[0023] An embodiment of the present invention is a method for preparing an ultra-low temperature and low deformation polished glazed brick body. The steps are as follows:

[0024] (1) After the base material is added into the ball mill for mixed ball milling, the additive is added in the stock tank and stirred evenly to obtain the mixed material;

[0025] (2) The mixed material is successively sieved, dried, granulated, pressed and formed to obtain the adobe;

[0026] (3) The adobe is fired at a temperature of 1140-1180° C., the holding time is 10-15 minutes, and the total firing time is 55-65 minutes to obtain a glazed tile adobe product.

[0027] The specific process parameters of the preparation method of the embodiment of the present invention are shown in Table 1.

[0028] Table 1 The material compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com