Building ceramic plate/brick and preparation method thereof

A technology of architectural ceramics and base materials, applied in the field of architectural ceramic materials, can solve the problems of not meeting the performance requirements of ceramic rock slabs, low flexural strength and fracture toughness, etc., and achieve ideal high-temperature deformation resistance, ensure strength, and avoid melting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

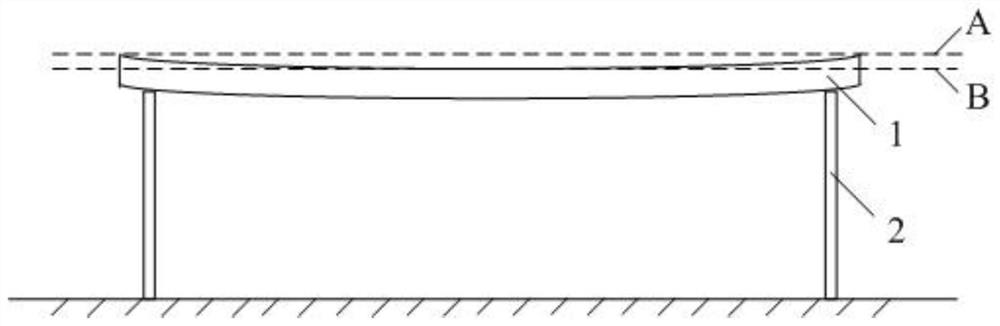

Image

Examples

preparation example Construction

[0062] Correspondingly, the present invention also discloses a method for preparing a building ceramic plate / brick, comprising:

[0063] (1) add the base material and additive of described building ceramic board / brick by proportioning, carry out ball milling mixing with water as medium to obtain mud;

[0064] (2) spray drying the mud into powder with a water content of 4-9 wt%;

[0065] (3) pressing and molding the powder with a press, and obtaining a green body after drying;

[0066] Under normal circumstances, dry powder pressing has lower requirements on the plasticity of the blank, so that it can be matched with the formula of the present invention and less alumina is introduced to reduce the sintering temperature. On the contrary, plastic molding has high plasticity to the blank, and a large amount of kaolin, mud and other plastic raw materials with high alumina content must be added to the blank, resulting in a high sintering temperature.

[0067] (4) After glazing is ...

Embodiment 1

[0073] (1) Formula: composed of base material and additives;

[0074] The raw material composition of the base material is bentonite 5wt%, borosilicate cullet 35wt%, ordinary cullet 7wt%, wollastonite 35wt%, fluorite 4wt%, calcined calcium phosphate 4wt%, kaolin 10wt%; relative to the base material, The additives are modified starch 0.5wt%, water glass 0.5wt%.

[0075] Among them, the chemical composition mass percentage of bentonite is: SiO 2 72.10%, Na 2 O+K 2 O 1.51%, Al 2 O 3 15.84%, Fe 2 O 3 1.12%, CaO+MgO 6.5%, TiO 2 0.15%, 2.78% loss on ignition.

[0076] The chemical composition mass percentage of high borosilicate cullet is: SiO 2 81.12%, Na 2 O+K 2 O 2.29%, Al 2 O 3 2.84%, Fe 2 O 3 0.11%, CaO+MgO+ZnO+BaO+SrO 0.43%, TiO 2 0.15%, B 2 O 3 13.06%.

[0077] The chemical composition mass percentage of ordinary cullet is: SiO 2 71.33%, Na 2 O+K 2 O 15.26%, Al 2 O 3 2.84%, Fe 2 O 3 0.21%, CaO+MgO+ZnO+BaO+SrO 10.21%, TiO 2 0.15%.

[0078]...

Embodiment 2

[0085] (1) Formula: composed of base material and additives;

[0086] The raw material composition of the base material is bentonite 6wt%, borosilicate cullet 46wt%, wollastonite fiber 30wt%, fluorite 4wt%, calcined calcium phosphate 4wt%, kaolin 10wt%; relative to the base material, the additive is modified starch 0.5wt%, water glass 0.5wt%.

[0087] Among them, the chemical composition mass percentage of bentonite is: SiO 2 72.10%, Na 2 O+K 2 O 1.51%, Al 2 O 3 15.84%, Fe 2 O 3 1.129%, CaO+MgO 6.5%, TiO 2 0.15%, 2.78% loss on ignition.

[0088] The chemical composition mass percentage of high borosilicate cullet is: SiO 2 81.12%, Na 2 O+K 2 O 2.29%, Al 2 O 3 2.84%, Fe 2 O 3 0.11%, CaO+MgO+ZnO+BaO+SrO 0.43%, TiO 2 0.15%, B 2 O 3 13.06%.

[0089] The wollastonite fiber has a diameter of 2 to 5 μm, a length of 16 to 60 μm, an aspect ratio of 8 to 12, and its chemical composition mass percentage is SiO 2 53.30%, CaO 42.80%, 3.90% loss on ignition.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com