Bone jade porcelain and method for manufacturing same

A technology for washing mud and lithium feldspar, which can be applied to other household utensils, clay products, household utensils, etc. It can solve the problems of narrow firing range, poor thermal stability, and difficult control, and achieve good light transmission and thermal stability. The effect of raising and lowering the firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

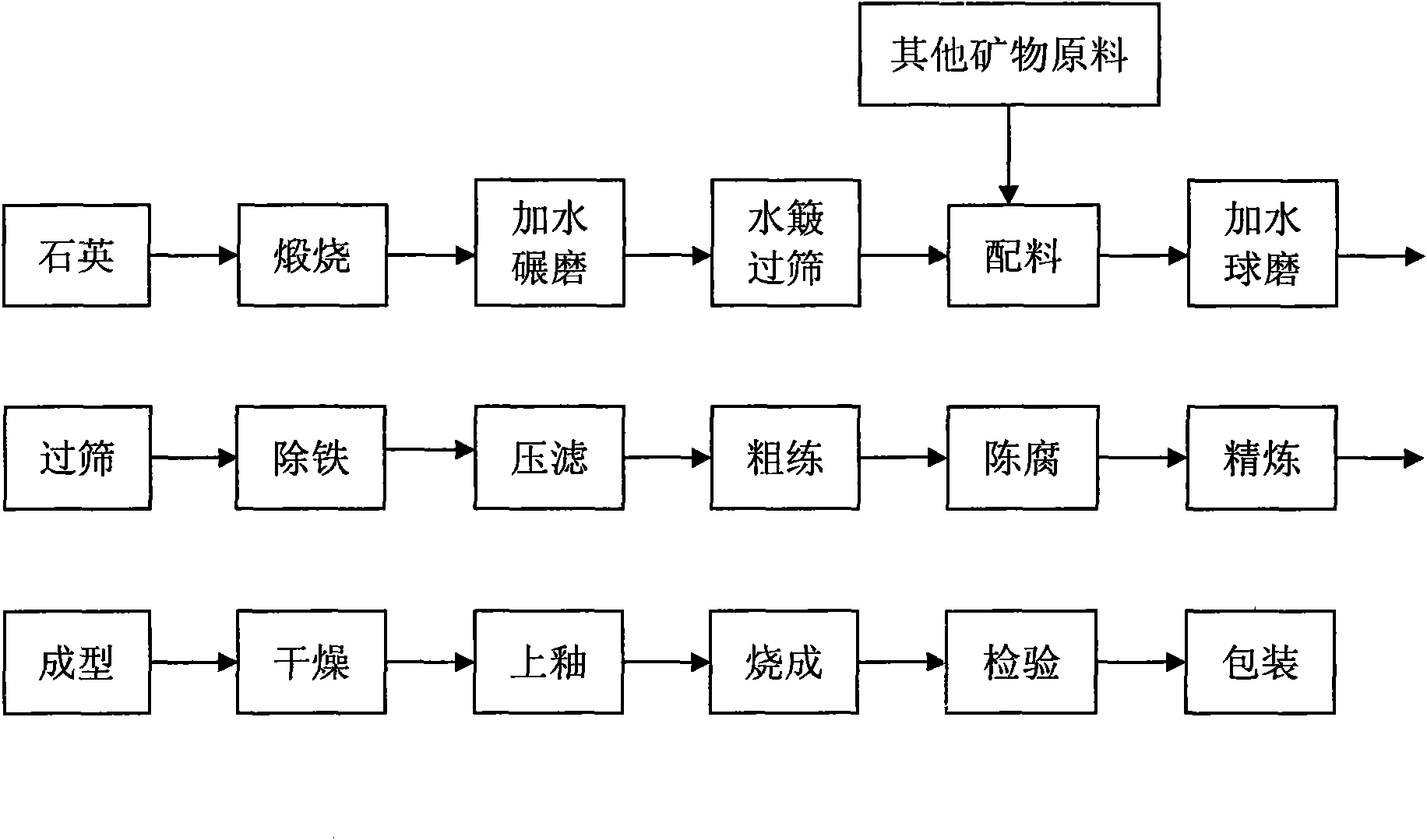

Method used

Image

Examples

Embodiment 1

[0015] The quartz is calcined at a temperature of 1000°C, ground with water, and sieved with water to make quartz particles with a particle size of 10-20 μm.

[0016] A composition with the following components and weight percentages was prepared: 15% of quartz, 20% of lithium feldspar, 8% of Australian alumina, 4% of Guizhou clay, 33% of Longyan kaolin washing mud and 20% of Huidong kaolin washing mud. The lithium feldspar is selected in which Li 2 O content is 1.8% or more.

[0017] Add water to the above composition in a ratio of 1:1.25 by weight, and mill it in a ball mill for 11 hours. The fineness of the ball milled composition is controlled at 0.4% after passing through a 250 mesh sieve, and then iron removal, press filtration dehydration, rough refining, stale, refining , become porcelain clay with a moisture content of 24%.

[0018] The above-mentioned porcelain clay is molded by grouting, dried, glazed, and fired in a kiln at 1320°C for 9 hours to become a bone jad...

Embodiment 2

[0021] The quartz is calcined at a temperature of 980°C, ground with water, and sieved with water to make quartz particles with a particle size of 10-20 μm.

[0022] A composition with the following ingredients and weight percentages is prepared: 10% of cooked quartz, 25% of hectorite, 10% of Australian alumina, 5% of Guizhou clay, 30% of Longyan kaolin washing mud and 20% of Huidong kaolin washing mud. The lithium feldspar is selected in which Li 2 O content is more than 2.0%;

[0023] The above composition is added with water in a ratio of 1:1.5 by weight, and ball milled in a ball mill for 10 hours. The fineness of the ball milled composition is controlled at 0.5% after passing through a 250 mesh sieve, and then iron removal, pressure filtration and dehydration, rough refining, stale, Refined porcelain clay with a moisture content of 26%.

[0024] The above porcelain clay is molded by grouting, dried, glazed, and fired in a kiln at 1340°C for 8 hours to become a bone jade...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com