Low cost low expansion ceramic zirconium-free white glaze and preparation method thereof

A low-expansion, low-cost technology, applied in the field of ceramic glaze, can solve the problems of large temperature fluctuation, narrow melting temperature range of white glaze, easy to break, etc., to solve the problem of controllable and adjustable expansion coefficient and whiteness, expansion coefficient , The effect of improving the production qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

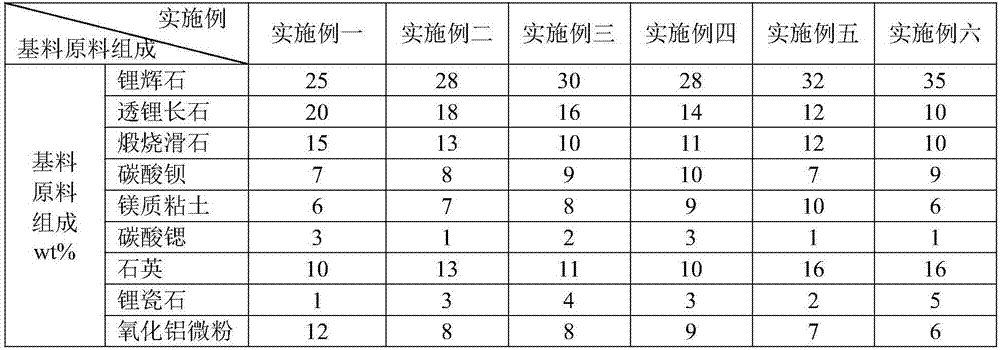

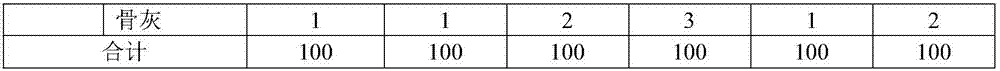

[0016] An example of a low-cost low-expansion ceramic zirconium-free white glaze of the present invention includes a base material and an additive, wherein the raw material composition of the base material is shown in Table 1.

[0017] Table 1 The composition of the base material of the low-cost and low-expansion ceramic zirconium-free white glaze of the embodiment of the present invention

[0018]

[0019]

[0020] The additives are carboxypropyl methyl cellulose (HPMC) (molecular weight 400-800) and sodium tripolyphosphate (STTP), and the amounts thereof are respectively 0.1 wt % and 0.30 wt % of the base material.

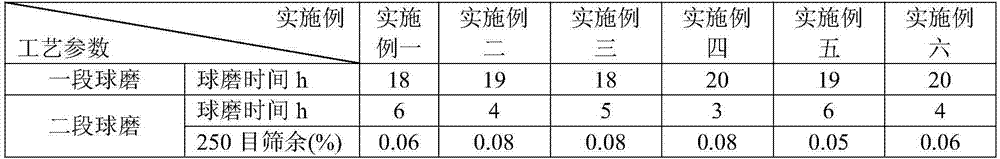

[0021] The preparation method of the low-cost low-expansion ceramic zirconium-free white glaze of the embodiment of the present invention is as follows:

[0022] First, the other raw materials except the alumina micropowder in the above-mentioned base material are subjected to one-stage ball milling together with the additives, and then the alumina micropo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com