Preparation method of reinforced bone china and product prepared therefrom

A technology of bone china and porcelain stone, applied to clay products, other household utensils, household utensils, etc., can solve problems such as tea stains, stains, easy cracking of products, easy scratches on glazed surfaces, etc., and achieve the production method Scientific and reasonable, fine and transparent porcelain, good transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

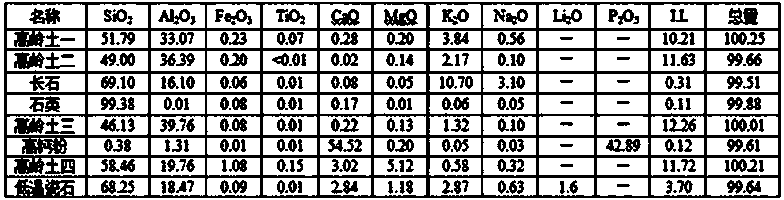

[0023] The formula weight percentage of strengthened bone china body is kaolin 1 15%, kaolin 2 18%, feldspar 10%, quartz 5%, kaolin 3 9%, kaolin 4 2%, high calcium powder 36%, low temperature china stone 5% ;

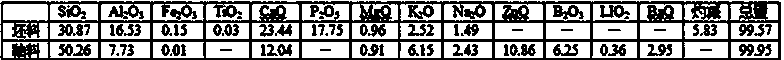

[0024] The weight percentage of strengthened bone china glaze is 10% kaolin, 34% feldspar, 6% quartz, 10% borax, 8% zinc oxide, 14% porcelain stone, 3% dolomite, 10% calcite, and 5% barium carbonate;

[0025] Weigh and mix the raw materials according to the billet formula requirements. After crushing, ball mill, sieve to remove iron, squeeze mud, mud and other processes to make mud. The fineness of the ball mill is 325 mesh sieve, and the sieve residue is less than 0.3%.

[0026] Weigh and mix the raw materials according to the requirements of the glaze formula, and make the glaze by ball milling and sieving to remove iron. The fineness of ball milling is 325 mesh sieve, the sieve residue is less than 0.1%, and the specific gravity is 1.25g / ml.

[0027] After drying an...

Embodiment 2

[0031] The formula weight percentage of strengthened bone china body is kaolin 1 18%, kaolin 2 15%, feldspar 12%, quartz 5%, kaolin 3 8%, kaolin 4 2%, high calcium powder 35%, low temperature china stone 5% ;

[0032] The weight percentage of strengthened bone china glaze is 11% kaolin, 36% feldspar, 7% quartz, 8% borax, 6% zinc oxide, 13% porcelain stone, 5% dolomite, 8% calcite, and 6% barium carbonate;

[0033] The raw materials are weighed and mixed according to the requirements of the billet formula. After crushing, the mud is made by ball milling, sieving to remove iron, squeezing mud, and mud refining. The fineness of ball milling is 325 mesh sieve, and the sieve residue is less than 0.4%.

[0034] Weigh and mix the raw materials according to the requirements of the glaze formula, and make the glaze by ball milling and sieving to remove iron. The ball milling fineness is 325 mesh sieve, the sieve residue is less than 0.15%, and the specific gravity is 1.26g / ml.

[0035...

Embodiment 3

[0039] The formula weight percentage of strengthened bone china body is kaolin 1 15%, kaolin 2 15%, feldspar 10%, quartz 8%, kaolin 3 8%, kaolin 4 4%, high calcium powder 35%, low temperature china stone 5% ;

[0040] The weight percentage of reinforced bone china glaze is 10% kaolin, 30% feldspar, 6% quartz, 9% borax, 7% zinc oxide, 14% porcelain stone, 6% dolomite, 12% calcite, and 6% barium carbonate;

[0041] The raw materials are weighed and mixed according to the requirements of the billet formula. After crushing, the mud is made by ball milling, sieving to remove iron, squeezing mud, and mud refining. The fineness of ball milling is 325 mesh sieve, and the sieve residue is less than 0.3%.

[0042] Weigh and mix the raw materials according to the requirements of the glaze formula, and make the glaze by ball milling and sieving to remove iron. The ball milling fineness is 325 mesh sieve, the sieve residue is less than 0.1%, and the specific gravity is 1.27g / ml.

[0043] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com