Blue-and-white bone jewelry delicate porcelain

A gemstone and bone technology, applied in the field of chemical composition for the preparation of gemstone porcelain, can solve the problems of gemstone glaze flow, material waste, and affecting work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, blue and white bone gem Linglong porcelain, comprise mud material and gem Linglong glaze, wherein: mud material formula comprises bone carbon 38-43 parts by weight, quartz 5-8 part, feldspar 16-20 part, raw 10-13 parts of sand, 7-9 parts of kaolin, 6-8 parts of porcelain powder, 8-9 parts of bentonite;

[0035] Gem Linglong glaze formula includes by weight: 14-18 parts of feldspar, 28-36 parts of quartz, 2-4 parts of sandstone, 12-15 parts of borax, 12-15 parts of light calcium carbonate, 2-3 parts of talc , 4-6 parts of barium carbonate, 3-6 parts of zinc oxide, 2 parts of zircon, 2 parts of soda ash, 0-3 parts of lithium carbonate, 5 parts of kaolin, 0.1 part of methyl cellulose.

Embodiment 2

[0036] Embodiment 2, the preparation method of blue-and-white bone gem Linglong porcelain, its technical process comprises raw material processing, compacting, belt mold drying, demoulding, drying, grinding blank, replenishing water, fine blank inspection, installing low-temperature plain kiln, low-temperature Bisque firing, inspection, decals, sandblasting, glaze spotting, glaze washing, high temperature kiln installation, high temperature biscuit firing, plain inspection, polishing, pasting of underglaze colored paper, low temperature decarbonization, inspection, glaze spraying, glaze firing kiln, Glaze firing, kiln opening, inspection, and storage of finished products,

[0037] Among them: the low-temperature biscuit firing temperature in the process is 600 degrees, and the firing time is 3 hours; the high-temperature biscuit firing temperature is 1230 degrees, and the firing time is 10 hours; the glaze firing temperature is 1130 degrees, and the firing time is 8 hours; The...

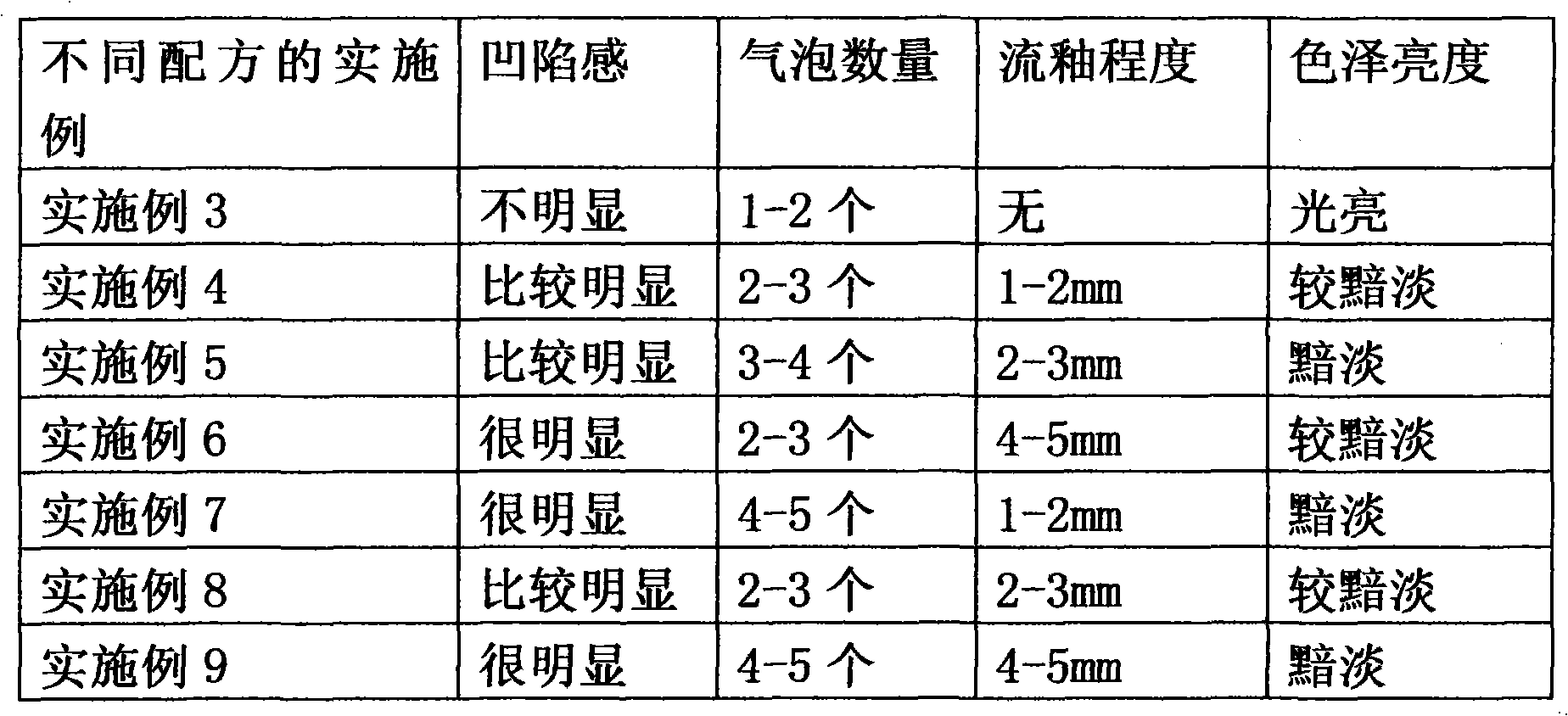

Embodiment 3

[0040] Embodiment 3, blue and white bone gem Linglong porcelain, wherein: mud formula 1 comprises 43 parts of bone carbon by weight ratio, 5 parts of quartz, 17 parts of feldspar, 10 parts of raw sand, 8 parts of kaolin, 8 parts of porcelain powder, 9 parts of bentonite.

[0041] Gem Linglong glaze formula 1 includes 16 parts by weight of feldspar, 32 parts of quartz, 3 parts of sandstone, 14 parts of borax, 14 parts of light calcium carbonate, 2 parts of talc, 2 parts of zircon, 6 parts of barium carbonate, 5 parts of zinc oxide, 2 parts of soda ash, 2 parts of lithium carbonate, 5 parts of kaolin, 0.1 part of methyl cellulose, 0.1 part of water glass. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com