Manufacturing process of crystal frit-containing exquisite glazes and exquisite products

A production process and frit glaze technology, which are applied to crystal frit and Linglong glaze containing crystal frit and the field of preparation thereof, can solve the problem that Linglong glaze is easy to generate bubbles, the yield is low, and the connection between Linglong glaze and bone china The problem of high cracking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

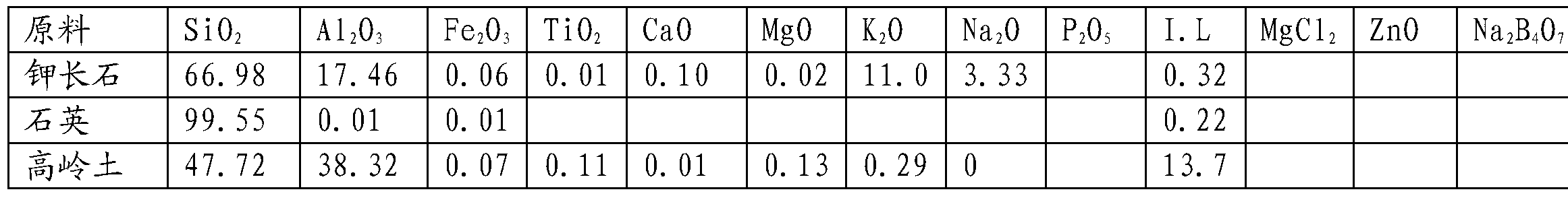

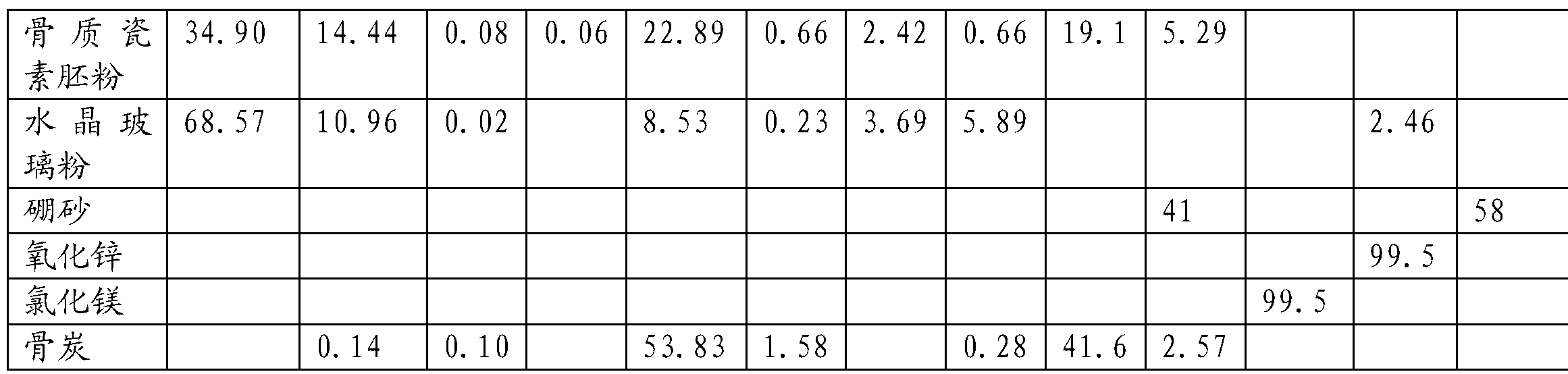

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Crystal frit as top glaze

[0029] Crystal glass powder: 50 parts, borax: 24 parts, potassium feldspar: 6 parts, quartz: 5 parts, zinc oxide: 6 parts, kaolin: 5 parts, magnesium chloride: 4 parts

[0030] Step A: Mix the mixed total weight with water in a ratio of 4:6;

[0031] Step B: After the mixture is put into a quick ball mill jar and ground for 24 hours, pass through a 350-mesh sieve to get fine powdered ingredients.

[0032] Step C: Take the bisque-fired ceramic bottle, spray the fine powder ingredients, put it into a kiln with a temperature of 1450-1560° C. and calcinate it for 10-12 hours, then take it out. The product has a smooth glazed surface.

Embodiment 2

[0033] Example 2: Crystal frit as top glaze

[0034] Crystal glass powder: 45 parts, borax: 24 parts, potassium feldspar: 8 parts, quartz: 8 parts, zinc oxide: 6 parts, kaolin: 5 parts, magnesium chloride: 4 parts

[0035] Step A: Mix the mixed total weight with water in a ratio of 4:6;

[0036] Step B: Put the mixture into a quick ball mill jar and grind for 24 hours, then pass through a 350-mesh sieve to get fine powder ingredients.

[0037] Step C: Take the bisque-fired ceramic bottle, spray the fine powder ingredients, put it into a kiln with a temperature of 1450-1560° C. and calcinate it for 10-12 hours, then take it out. The product has a smooth glazed surface.

Embodiment 3

[0038] Example 3: Crystal frit as top glaze

[0039] Crystal glass powder: 49 parts, borax: 24 parts, potassium feldspar: 8 parts, quartz: 8 parts, zinc oxide: 2 parts, kaolin: 5 parts, magnesium chloride: 4 parts

[0040] Step A: mix the mixed total weight with water in a ratio of 5:5;

[0041] Step B: Put the mixture into a quick ball mill jar and grind for 24 hours, then pass through a 350-mesh sieve to get fine powder ingredients.

[0042] Step C: Take the bisque-fired ceramic bottle, spray the fine powder ingredients, put it into a kiln with a temperature of 1450-1560° C. and calcinate it for 10-12 hours, then take it out. The product has a smooth glazed surface.

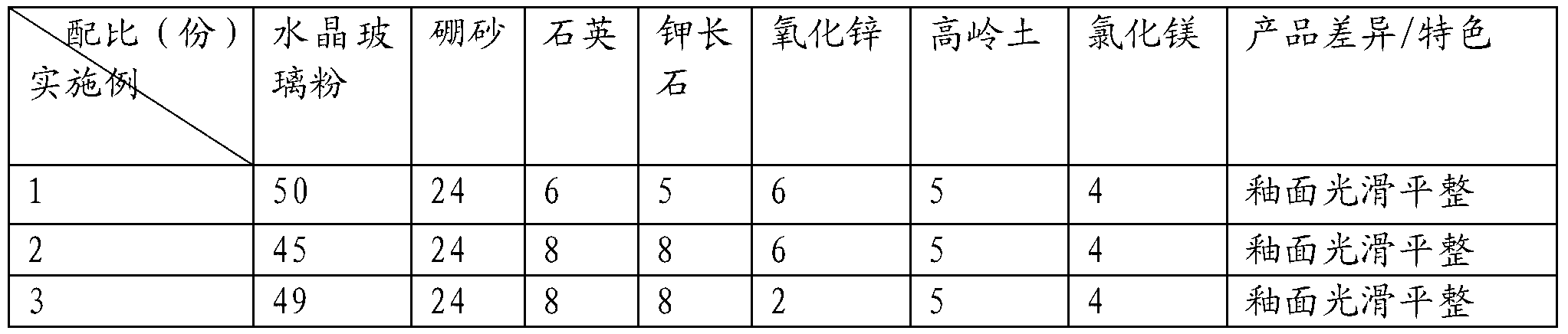

[0043] Table 2

[0044]

[0045] As shown in Table 2, the crystal frit glaze prepared by the present invention has a good degree of bonding with the body, is not easy to crack, has good light transmittance, and reduces the occurrence of air bubbles in the Linglong glaze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com