Lead and cadmium free fritted glaze for bone China with high acid resistance and alkali resistance

A lead-free frit, acid and alkali resistance technology, applied in the field of ceramic glaze, can solve the problems such as no research and discussion on the chemical stability of the enamel, and insufficient attention to the chemical stability of the enamel, that is, acid and alkali resistance. Poor acid and alkali resistance and lead-containing problems, good glaze adaptability and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

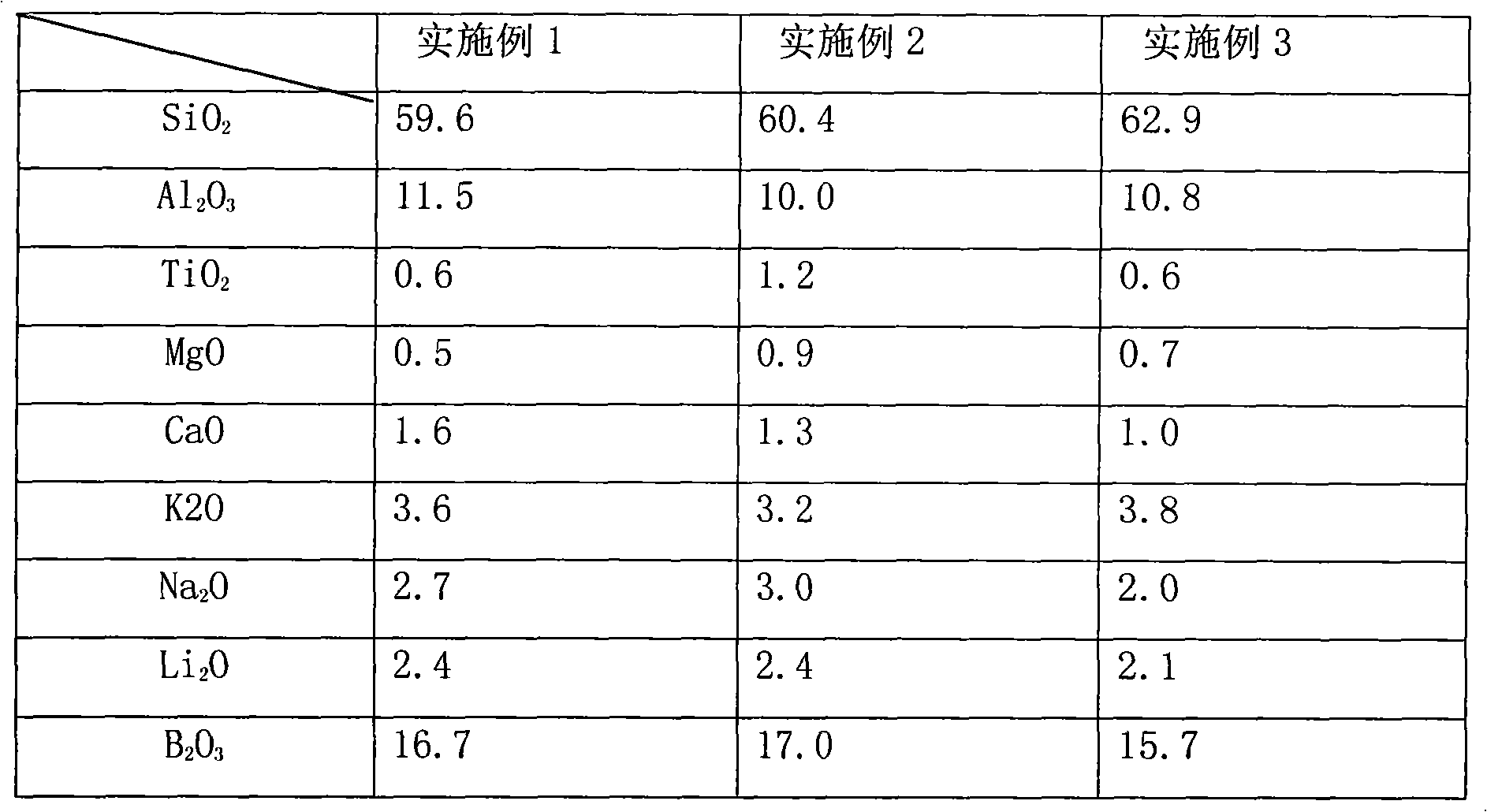

Embodiment 1

[0023] The high acid and alkali resistant lead-free frit glaze described in Example 1 is prepared from the following raw materials in percentage by weight:

[0024] Quartz 28.0%, feldspar 30.0%, alumina 4.0%, titanium dioxide 0.5%, boric acid 25.5.0%, limestone 2.0%, calcined talc 1.0%, lithium carbonate 5.0%, sodium carbonate 4.0%.

[0025] All batch materials are mixed evenly, melted in a frit furnace at 1340-1350°C, and quenched with water to obtain a frit. Then, the frit is ground in a ball mill at room temperature with water as the medium to make a glaze slurry, and the fineness of the glaze slurry is controlled to be below 10 μm, accounting for 81-83%.

[0026] The prepared glaze slurry is applied to the bisque-fired high-grade bone china biscuit and fired at a temperature of 1100-1150° C. to obtain high-quality bone china products. The enamel surface of the product is delicate, smooth, smooth and glossy. At the same time, it has been proved by experiments that the con...

Embodiment 2

[0028] The high acid and alkali resistant lead-free frit glaze described in embodiment 2 is prepared from the following raw materials in weight percent:

[0029] Quartz 29.5%, feldspar 27.0%, alumina 3.5%, titanium dioxide 1.0%, boric acid 26.0%, limestone 1.5%, calcined talc 2.0%, lithium carbonate 5.0%, sodium carbonate 4.5%.

[0030] Mix all batch materials evenly, melt in a frit furnace at 1350-1360°C, and then water-quench the frit. Then, the frit is ground in a ball mill at room temperature with water as the medium to make a glaze slurry, and the fineness of the glaze slurry is controlled to be below 10 μm, accounting for 82.0-84.0%.

[0031]The prepared glaze slurry is applied to the bisque-fired high-grade bone china biscuit and fired at a temperature of 1120-1170° C. to obtain high-quality bone china products. The enamel surface of the product is delicate, smooth, smooth and glossy. At the same time, it has been proved by experiments that the content of lead, cadmiu...

Embodiment 3

[0033] The high acid and alkali resistant lead-free frit glaze described in embodiment 3 is prepared from the following raw materials in percentage by weight:

[0034] Quartz 31.0%, feldspar 31.5.0%, alumina 3.0%, titanium dioxide 0.5%, boric acid 24.0%, limestone 1.0%, calcined talc 1.5%, lithium carbonate 4.5%, sodium carbonate 3.0%.

[0035] Mix all batch materials evenly, melt in a frit furnace at 1350-1360°C, and then water-quench the frit. Then, the frit is ground in a ball mill at room temperature with water as the medium to make a glaze slurry, and the fineness of the glaze slurry is controlled to be below 10.0 μm, accounting for 82.0-84.0%.

[0036] The prepared glaze slurry is applied to the bisque-fired high-grade bone china biscuit and fired at a temperature of 1110-1160° C. to obtain high-quality bone china products. The enamel surface of the product is delicate, smooth, smooth and glossy. At the same time, it has been proved by experiments that the content of l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com