Lead-free and cadmium-free bone china glaze and preparation process thereof

A preparation process and technology of bone china, applied in the field of lead-free and cadmium-free bone china glaze, can solve problems such as harm to human body, and achieve the effect of high glaze hardness, pure color and good gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

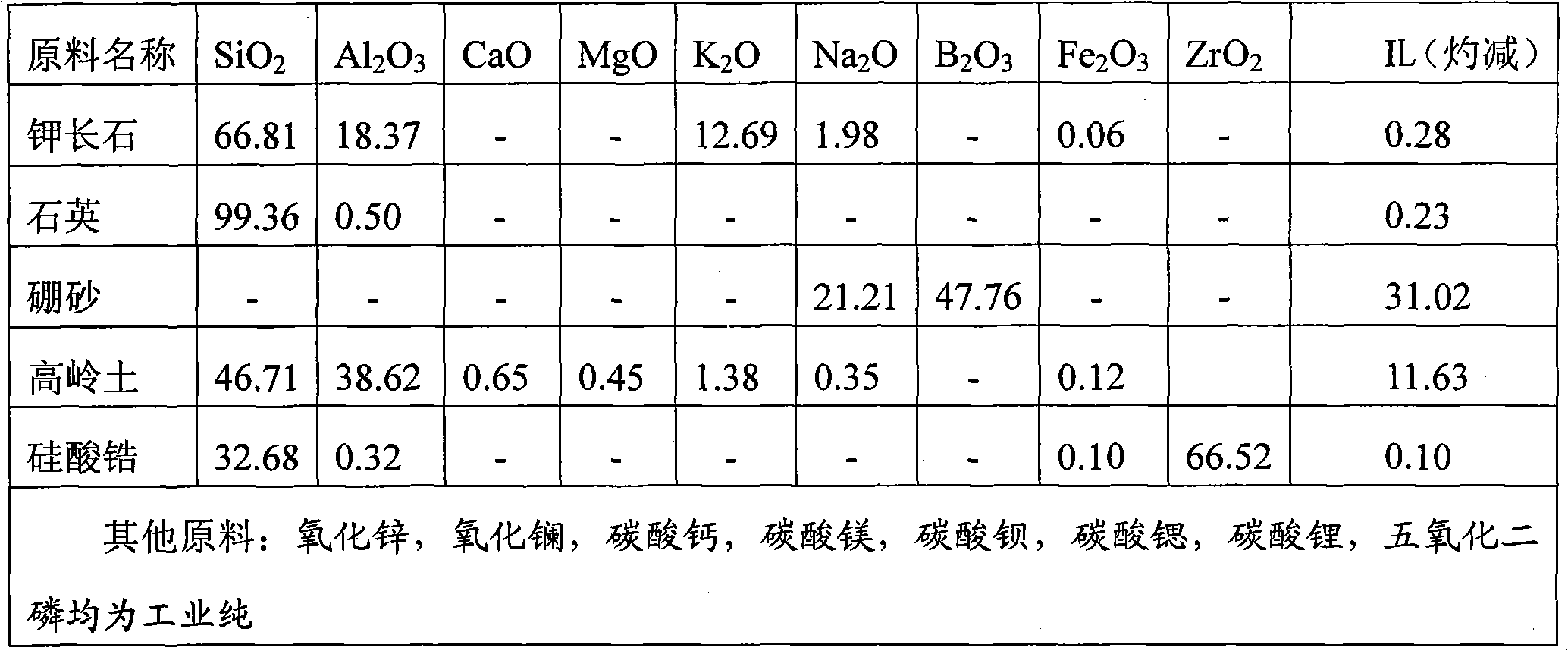

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: with 32 parts of quartz powder (200 orders), potassium feldspar powder (200 orders), 33 parts, 10 parts of borax, 3 parts of zinc oxides, 2 parts of zirconium silicates, 2 parts of lanthanum oxides, 7 parts of calcium carbonate, 2 parts of magnesium carbonate, 2 parts of barium carbonate, 3 parts of strontium carbonate, 4 parts of lithium carbonate. After mixing the above raw materials evenly, melt them at 1380℃~1450℃, put them into cold water and quench them into a frit.

[0015] Put the frit into a ball mill, add water, 3% kaolin and 0.02% ammonium chloride to grind into a glaze slurry, the specific gravity of the glaze slurry is controlled at 1.65-1.72kg / l, and the fineness is controlled at less than 0.03% on a 10,000-hole sieve. Spray the glaze on the bone china biscuit that has been fired at a high temperature of 1250-1280°C, dry it, put it into a kiln, and fire it at 1050-1180°C.

Embodiment 2

[0016] Embodiment 2: with 21 parts of quartz powder (200 orders), potassium feldspar powder (200 orders), 35 parts, 6 parts of borax, 4 parts of zinc oxides, 5 parts of zirconium silicates, 3 parts of lanthanum oxides, 13 parts of calcium carbonate, 3 parts of barium carbonate, 5 parts of strontium carbonate, 2 parts of lithium carbonate, 3 parts of phosphorus pentoxide. After mixing the above raw materials evenly, melt them at 1380℃~1450℃, put them into cold water and quench them into a frit.

[0017] Put the frit into a ball mill, add water, 5% kaolin and 0.025% polyvinyl alcohol to grind it into a glaze slurry. The specific gravity of the glaze slurry is controlled at 1.65-1.72kg / l, and the fineness is controlled at less than 0.03% on a million-hole sieve. Spray the glaze on the bone china biscuit that has been fired at a high temperature of 1250-1280 ℃, put it into a kiln after drying, and fire it at 1050-1180 ℃.

Embodiment 3

[0018] Embodiment 3: 25 parts of quartz powder (200 orders), potassium feldspar powder (200 orders), 27 parts, 5 parts of kaolin, 12 parts of borax, 5 parts of zinc oxide, 1 part of zirconium silicate, 0.5 part of lanthanum oxide, carbonic acid 10.5 parts of calcium, 4 parts of barium carbonate, 1 part of strontium carbonate, 4 parts of lithium carbonate, 5 parts of phosphorus pentoxide. After mixing the above raw materials evenly, melt them at 1380℃~1450℃, put them into cold water and quench them into a frit.

[0019] Put the frit into a ball mill, add water and 8% kaolin to grind it into a glaze slurry, the specific gravity of the glaze slurry is controlled at 1.65-1.72kg / l, and the fineness is controlled at less than 0.03% on a million-hole sieve. Spray the glaze on the bone china biscuit that has been fired at a high temperature of 1250-1280°C, dry it, put it into a kiln, and fire it at 1020-1180°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com