Production technology for producing spontaneous glaze bone china by efficient utilization of desert material

A production process and self-generated glaze technology, applied in the field of ceramics, can solve the problems of high labor costs, poor growth of the middle layer of the blank glaze, time-consuming and labor-intensive firing process, etc., to reduce the utilization of mineral resources, reduce water consumption, and reduce mining and production costs. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A production process for making self-glazed bone china with high utilization of desert materials. The composition and weight percentage of bone china mud are: sand grains from desert 50%; halloysite 20%; feldspar 15%; calcium hydroxyphosphate 8% ; Nano spodumene 3%; Talc 3%; Nano zircon sand 1%.

[0062] Wherein, the chemical composition in the bone china mud is by weight percentage: SiO 2 : 46%; Al 2 o 3 : 17%; CaO: 16%; Na 2 O+K 2 O: 2.4%; Fe 2 o 3 : 1.6%; TiO 2 : 0.3%; LiO 2 : 0.01%; P 2 o 5 : 0.07%; ZrO 2 : 0.7%.

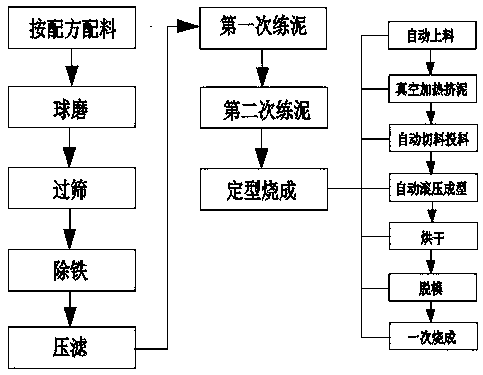

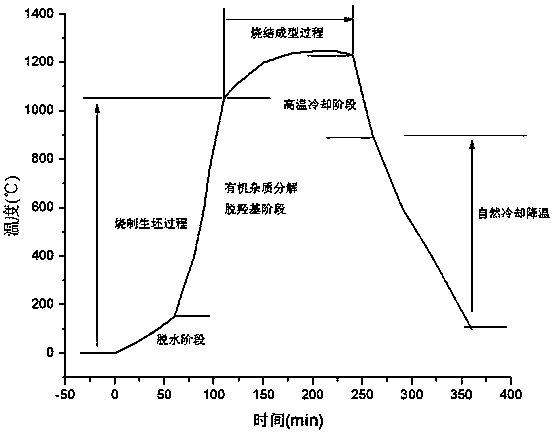

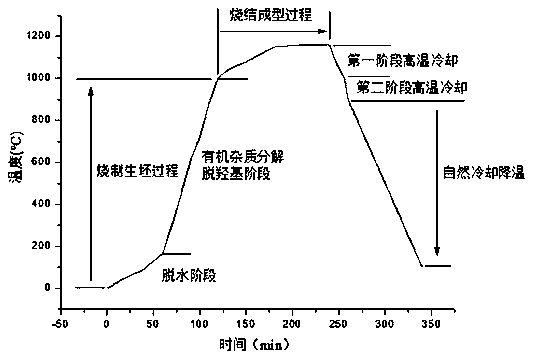

[0063] Among them, the technological process of preparing bone china from the above-mentioned bone china mud is as follows: according to the formula ingredients (by weight percentage), 50% sand from the desert, 20% halloysite, 15% feldspar, 8% Hydroxy calcium phosphate, 3% nano-scale spodumene, 3% talc and 1% nano-scale zircon sand are put into a ball mill for mixed grinding, wherein the material: ball: water is 1:1.5:0.5, and the prepared Un...

Embodiment 2

[0066] A production process for making self-glazed bone china with high utilization of desert materials. The bone china mud composition and weight percentage are: sand grains from the desert: 57%; halloysite: 15%; feldspar: 20%; hydroxyphosphoric acid Calcium: 4%; Nano Spodumene: 2%; Talc: 1%; Nano Zircon Sand: 1%.

[0067] Wherein, the chemical composition in the bone china mud is by weight percentage: SiO 2 : 54%; Al 2 o 3 : 20%; CaO: 7%; Na 2 O+K 2 O: 2.8%; Fe 2 o 3 : 1.8%; TiO 2 : 0.4%; LiO 2 : 0.2%; P 2 o 5 : 0.08%; ZrO 2 : 0.7%.

[0068] Among them, the technological process of preparing bone china from the above-mentioned bone china mud is as follows: 57% of sand from the desert, 15% of halloysite, 20% of feldspar, 4% Calcium hydroxyphosphate, 2% nano-scale spodumene, 1% talc and 1% nano-scale zircon sand are put into a ball mill for mixed grinding, wherein the material: ball: water is 1:1.5:0.5, and the prepared Uniformly mixed mud; then, the uniformly mix...

Embodiment 3

[0071] A production process for making self-glazed bone china with high utilization of desert materials. The bone china mud composition and weight percentage are: 52% sand grains from the desert; 21% halloysite; 16% feldspar; 6% calcium hydroxyphosphate ; Nano spodumene 2%; Talc 2%; Nano zircon sand 1%.

[0072] Wherein, the chemical composition in the bone china mud is by weight percentage: SiO 2 : 50%; Al 2 o 3 : 19%; CaO: 11%; Na 2 O+K 2 O: 2.6%; Fe 2 o 3 : 1.7%; TiO 2 : 0.35%; LiO 2 : 0.5%; P 2 o 5 : 0.1%; ZrO 2 : 0.7%.

[0073] Among them, the technological process of preparing bone china from the above-mentioned bone china mud is as follows: 52% sand from desert, 21% halloysite, 16% feldspar, 6% Hydroxy calcium phosphate, 2% nano-scale spodumene, 2% talc and 1% nano-scale zircon sand are put into a ball mill for mixed grinding, wherein the material: ball: water is 1:1.5:0.5, and the prepared Uniformly mixed mud; then, the uniformly mixed mud goes through sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com