Solar cell packaging adhesive film with high light conversion efficiency

A technology of solar cells and conversion efficiency, applied in photovoltaic power generation, circuits, adhesives, etc., can solve the problems of narrow absorption band of rare earth ions, complex preparation process, low absorption coefficient, etc., and achieve high utilization efficiency and good photostability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

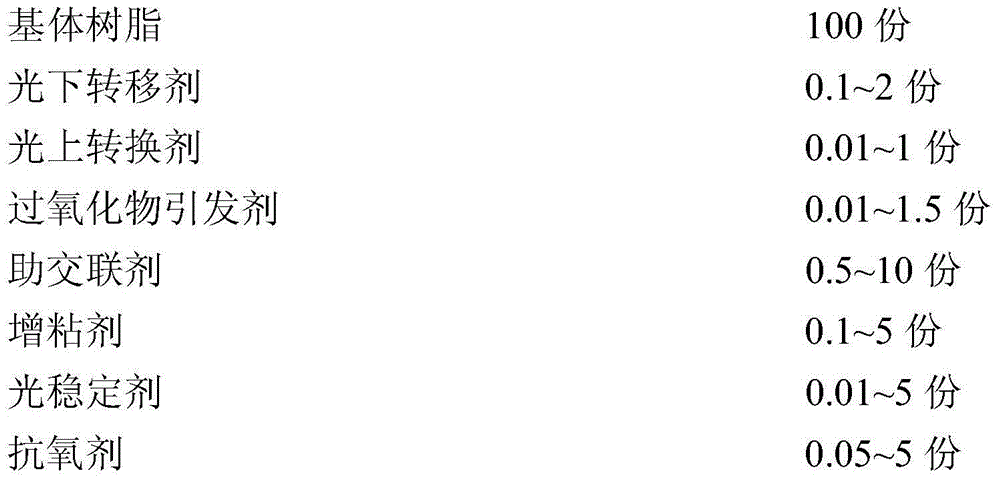

Method used

Image

Examples

preparation example Construction

[0021] The method for preparing semiconductor quantum dots is a common method for those skilled in the art.

[0022] The size of the semiconductor quantum dots must be in a quantum confinement state, that is, less than 10nm. Based on the maximum utilization of the spectrum in the range of 300-500nm, that is, the widest absorption band, the standard deviation of the size distribution of the quantum dots is less than 30% of the average size and greater than 10% of the average size. If the standard deviation is too small, it means that the size of the quantum dots is too concentrated, resulting in a narrow absorption band. If the standard deviation is too large, it means that the size of the quantum dots is too dispersed, which will cause the absorption coefficient of each specific wavelength to decrease. The emission spectrum of the semiconductor quantum dots can be adjusted by the type and size of the quantum dots in the range of 500-1100 nm.

[0023] In order to make the sem...

Embodiment 1

[0055] Si quantum dots with an average size of 5 nm and a standard deviation of 0.5 nm were surface treated with acrylic.

[0056] 20% Er 3+ Doped inorganic phosphor (the structural formula is expressed as NaY 0.8 f 4 :Er 3+ 0.2 ) is surface-coated with polymethyl methacrylate.

[0057] In terms of parts by mass, 100 parts of EVA with VA content of 30wt%, 2 parts of Si quantum dots through surface treatment, and NaY coated on the surface 0.8 f 4 :Er 3+ 0.2 1 part, 1 part of tert-butylperoxycaprylydecanoic acid, 0.5 part of trimethylolpropane trimethacrylate, 0.2 part of vinyltrimethoxysilane, 2,4-dichloro-6-(4-morpholine base)-1,3,5-triazine 0.1 parts were pre-mixed and then extruded and granulated with a twin-screw extruder. Extrude the produced particles with a single-screw extruder, and the extruded product is cast into a film, and then wound up after cooling to obtain a film with a thickness of 0.45 mm, which is designated as S1.

Embodiment 2

[0059] Si quantum dots with an average size of 10 nm and a standard deviation of 3 nm were surface treated with undecylenic acid surface treatment.

[0060] 50% Er 3+ Doped inorganic phosphor (the structural formula is expressed as NaY 0.5 Cl 4 :Er 3+ 0.5 ) is surface-coated with urethane resin.

[0061] In terms of parts by mass, 100 parts of EVA with VA content of 25wt%, 0.1 part of Si quantum dots through surface treatment, NaY coated on the surface 0.5 Cl 4 :Er 3+ 0.5 0.01 part, 0.5 part of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 1 part of propoxylated glycerin triacrylate, γ-methacryloxypropyl trimethoxy 0.3 parts of silane and 0.2 parts of bis-2,2,6,6-tetramethylpiperidinol sebacate were pre-mixed and then extruded and granulated with a twin-screw extruder. Extrude the prepared particles with a single-screw extruder, cast the extruded product into a film, and wind it up after cooling to obtain a film with a thickness of 0.45 mm, which is designated as S2. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com