High-gloss PTFE (polytetrafluoroethylene) anti-drop agent and preparation method thereof

An anti-drip agent, PTFE technology, applied in the field of high-gloss PTFE anti-drip agent and its preparation, can solve the problems of complex process flow, poor product quality, complicated process, etc., and achieve simple and controllable process operation and product particle size. The effect of simple control and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

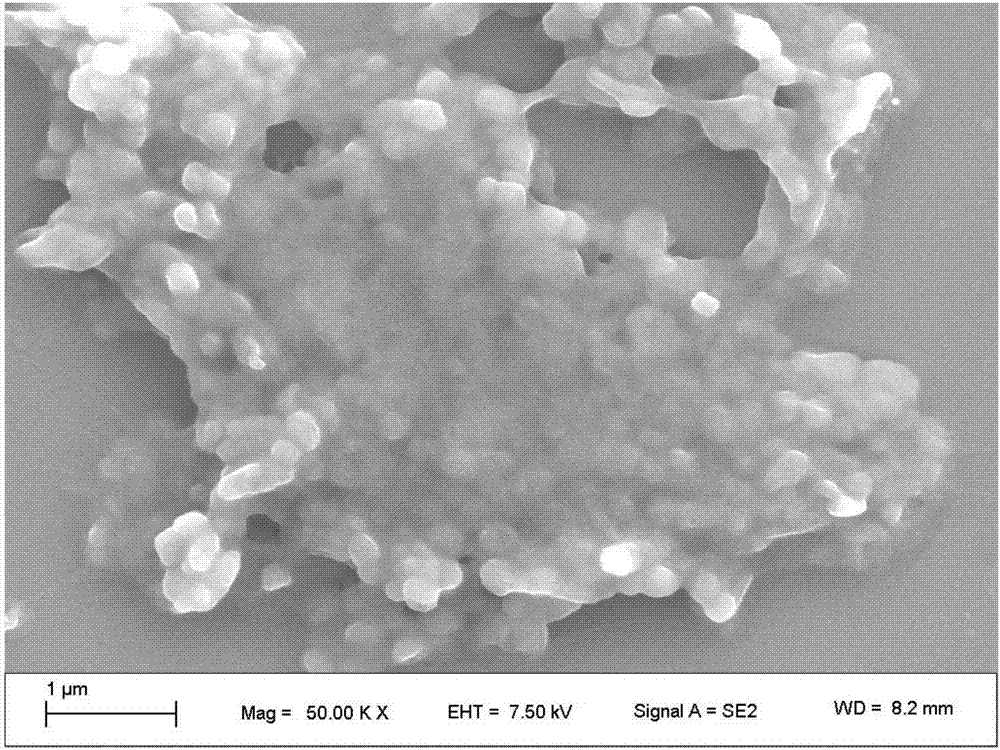

[0045] (1) Weigh 100 g of commercially available polytetrafluoroethylene emulsion with 60wt% polytetrafluoroethylene content and a particle size of 0.1-0.5um, and simultaneously weigh 6g of styrene monomer and emulsify it with 30mg sodium dodecylsulfonate Then pour it into the polytetrafluoroethylene emulsion and stir it evenly, and then place it in a gamma ray source for irradiation treatment with an absorbed dose of 100Gy.

[0046] (2) Add 60 mg of initiator potassium persulfate to the PTFE emulsion treated by (1), stir to dissolve it in the PTFE emulsion, and start heating to 85 °C after nitrogen gas for 30 minutes, and slowly add styrene dropwise after 10 minutes The monomer, the amount of styrene is 12g, after the styrene monomer is added dropwise, slowly add 2.4g of cross-linking agent divinylbenzene dropwise. Under anaerobic conditions, the stirring rate is 400-500r / min, and the grafting reaction is carried out for 10h to obtain the modified PTFE product;

[0047] (3) ...

Embodiment 2

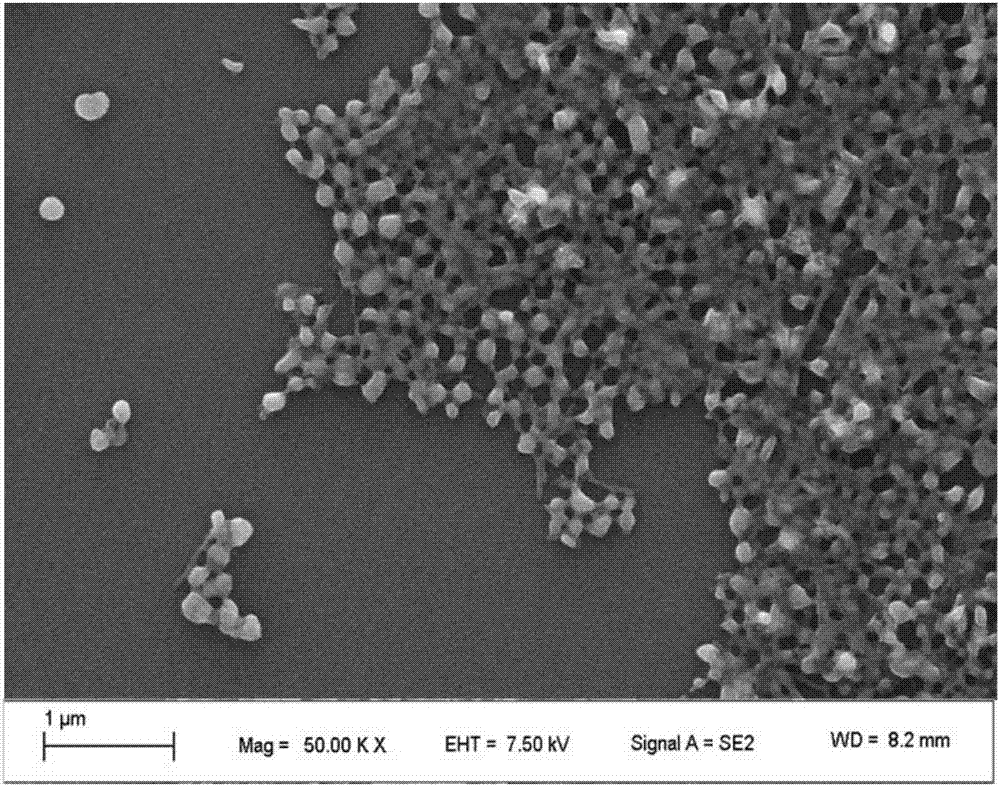

[0049] (1) Measure 100g after diluting the commercially available PTFE emulsion with PTFE content of 60wt% and particle size of 0.1-0.5um to 5wt%, and weigh 25mg of styrene monomer at the same time, and use 25mg per thousand A sodium dodecyl sulfonate aqueous solution is emulsified and poured into a polytetrafluoroethylene emulsion and stirred evenly, and then placed in a gamma ray source for irradiation treatment with an absorbed dose of 5Gy.

[0050] (2) Add 25 mg of 1 / 1,000 ammonium persulfate aqueous solution to the PTFE emulsion treated by (1), stir to dissolve it in the PTFE emulsion, and start heating to 40 °C after 30 minutes of nitrogen gas, and start to slow down after 10 minutes. Add 50 mg of styrene monomer dropwise, and slowly add 12.5 mg of a cross-linking agent divinylbenzene solution dropwise after the addition of the monomer is completed. Under anaerobic conditions, the stirring rate is 100-150r / min, and the grafting reaction is carried out for 3 hours to obta...

Embodiment 3

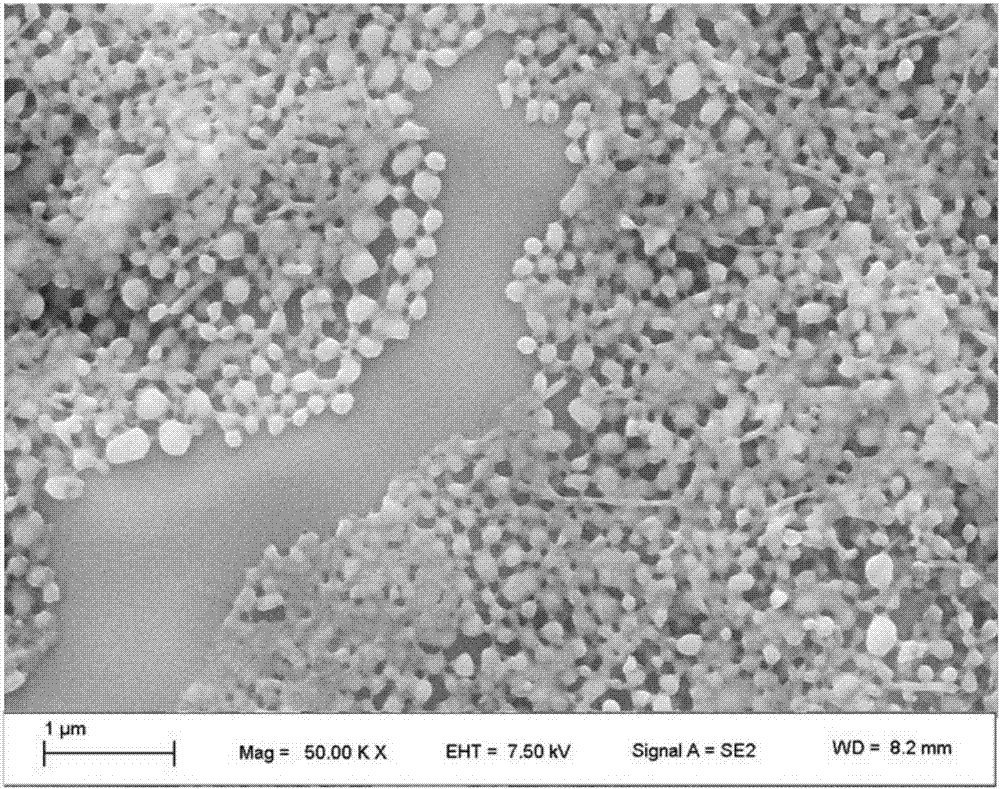

[0053] (1) Dilute the commercially available PTFE emulsion with a polytetrafluoroethylene content of 60wt% and a particle size of 0.1-0.5um to 40wt% and measure 100g, and weigh 0.4g of acrylonitrile monomer at the same time, emulsify with 1mgOSP1380 Pour it into the polytetrafluoroethylene emulsion and stir evenly, then place it in a gamma ray source for irradiation treatment, and the absorbed dose is 50Gy.

[0054] (2) Add 4 mg of initiator ammonium persulfate to the PTFE emulsion treated by (1), stir to dissolve it in the PTFE emulsion, and start heating to 50 °C after nitrogen gas for 30 minutes, and slowly add acrylonitrile dropwise after 10 minutes 4 g of monomers, after the addition of the monomers, slowly add 40 mg of the cross-linking agent triallyl isocyanurate dropwise. Under anaerobic conditions, the stirring rate is 300-400r / min, and the grafting reaction is carried out for 4 hours to obtain the modified PTFE product;

[0055] (3) Filter the modified PTFE product,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com