Patents

Literature

64results about How to "Process operation is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

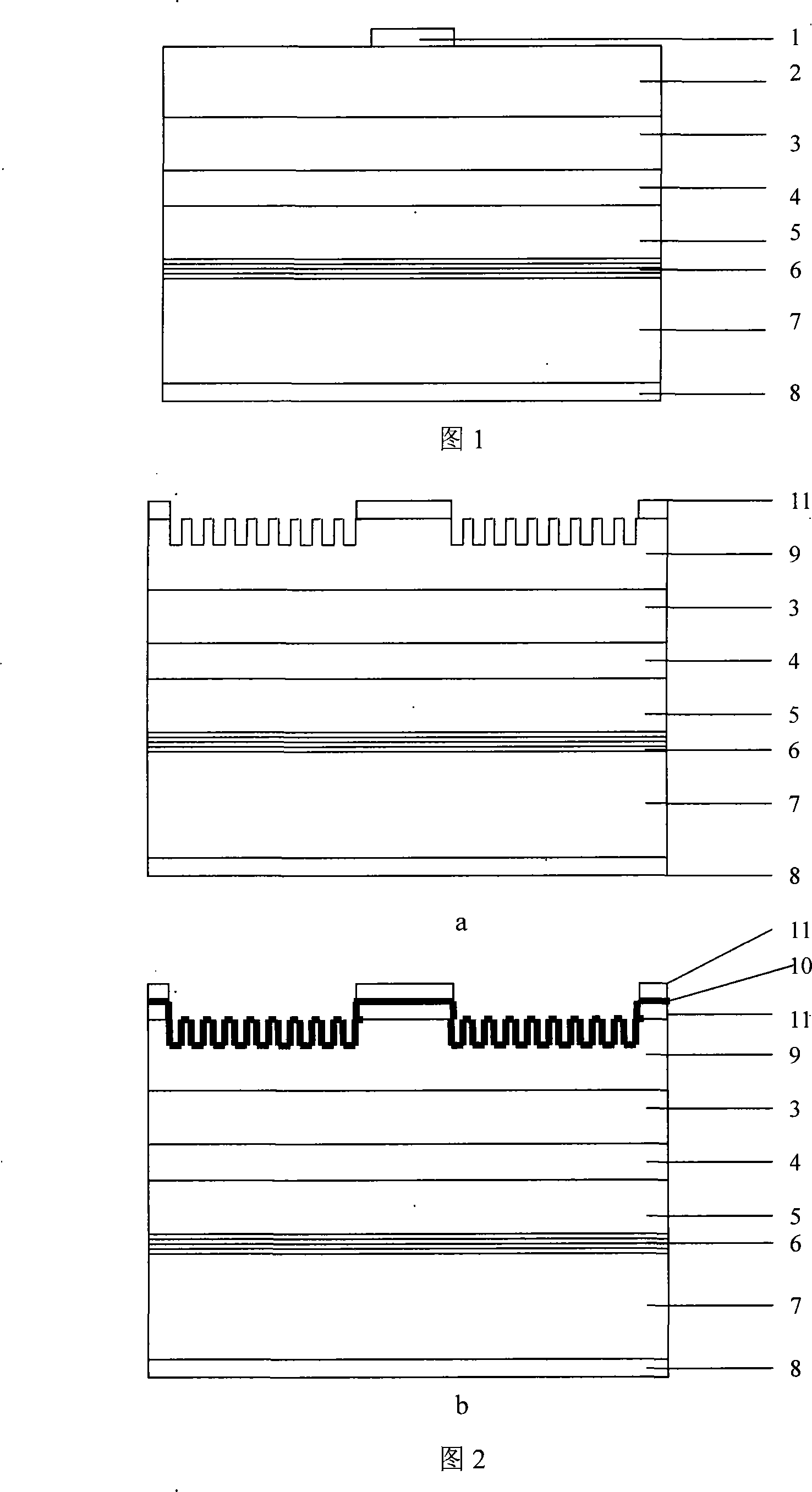

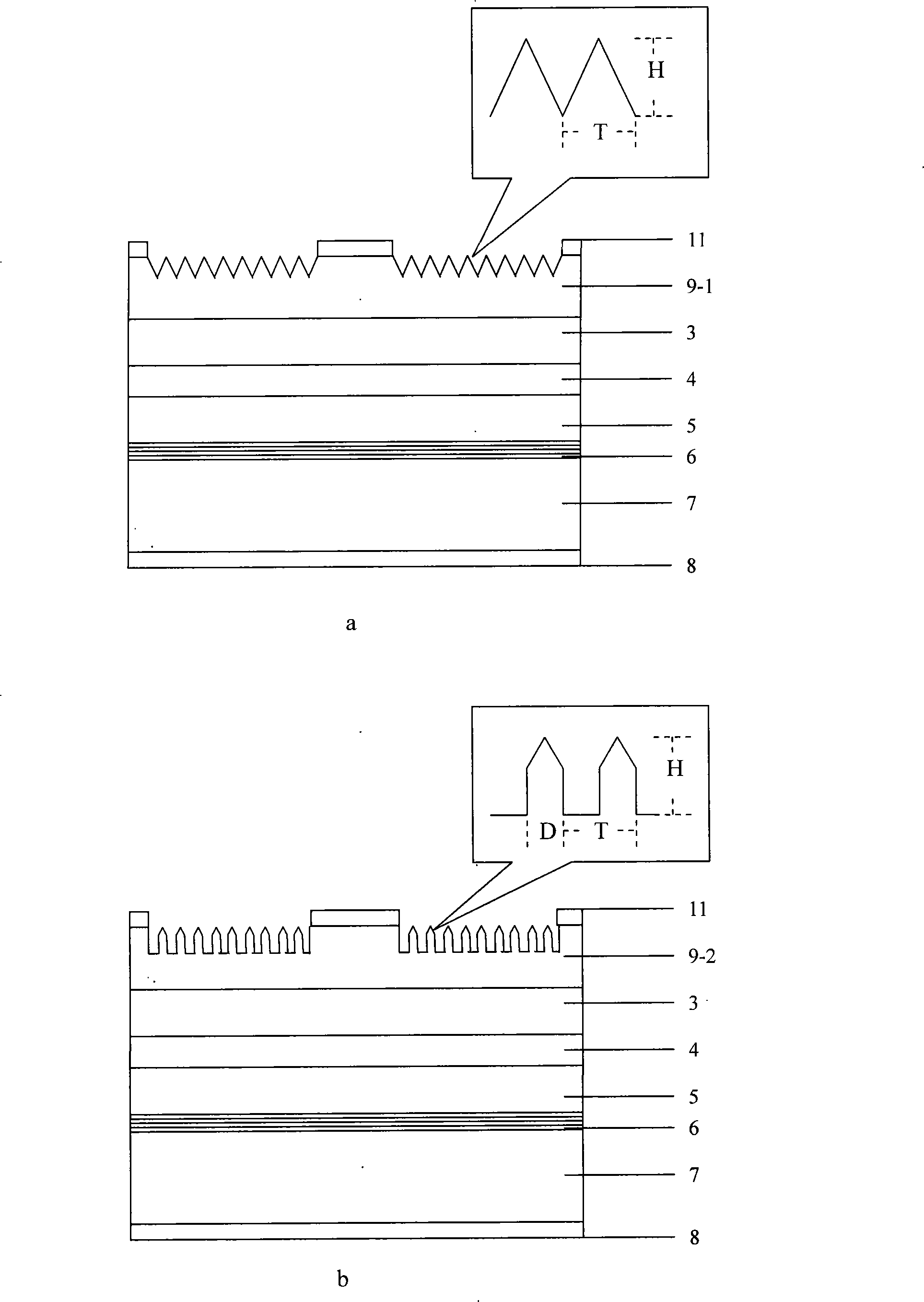

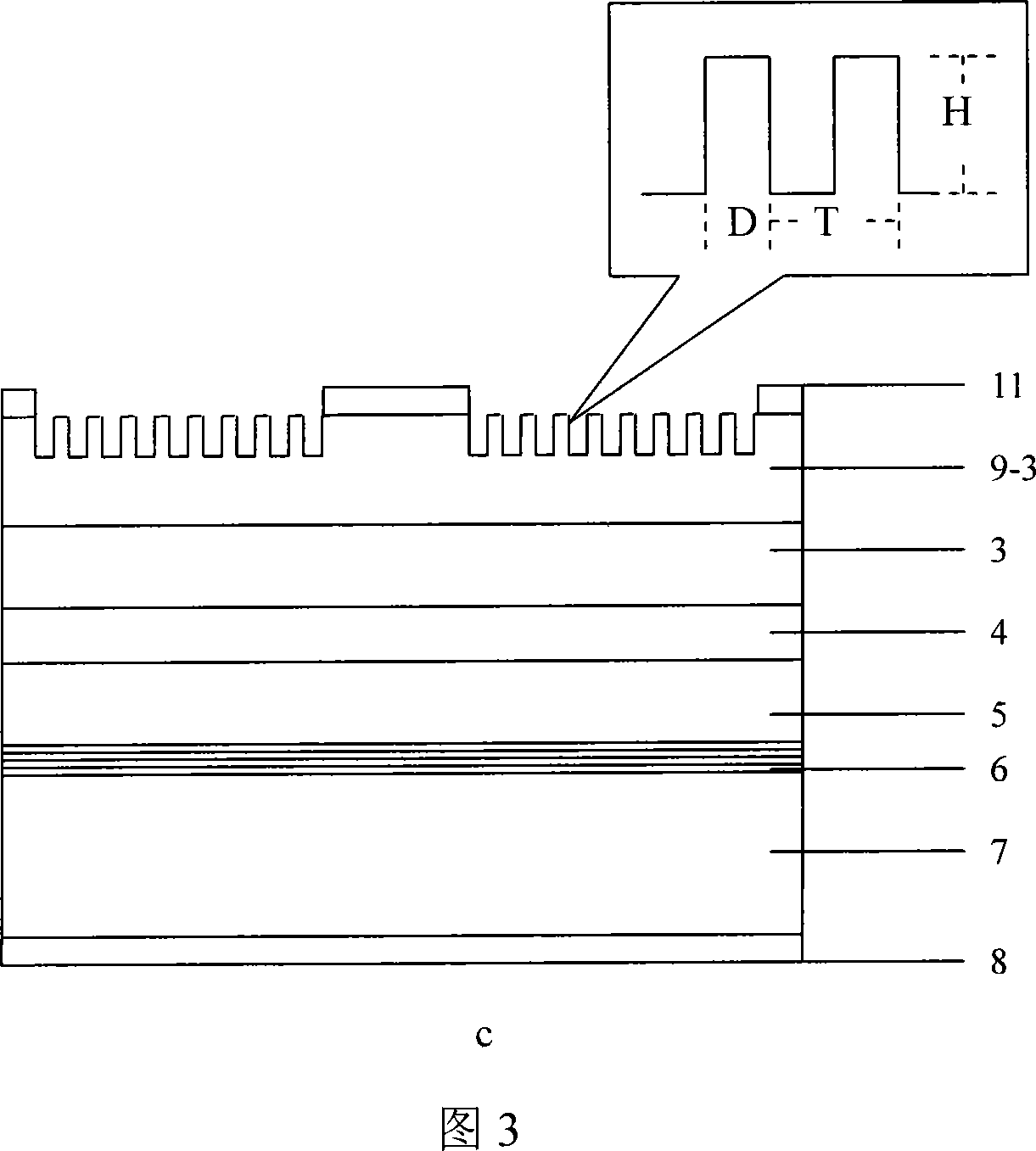

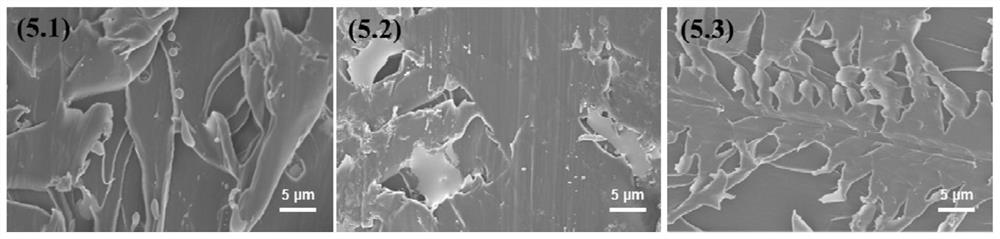

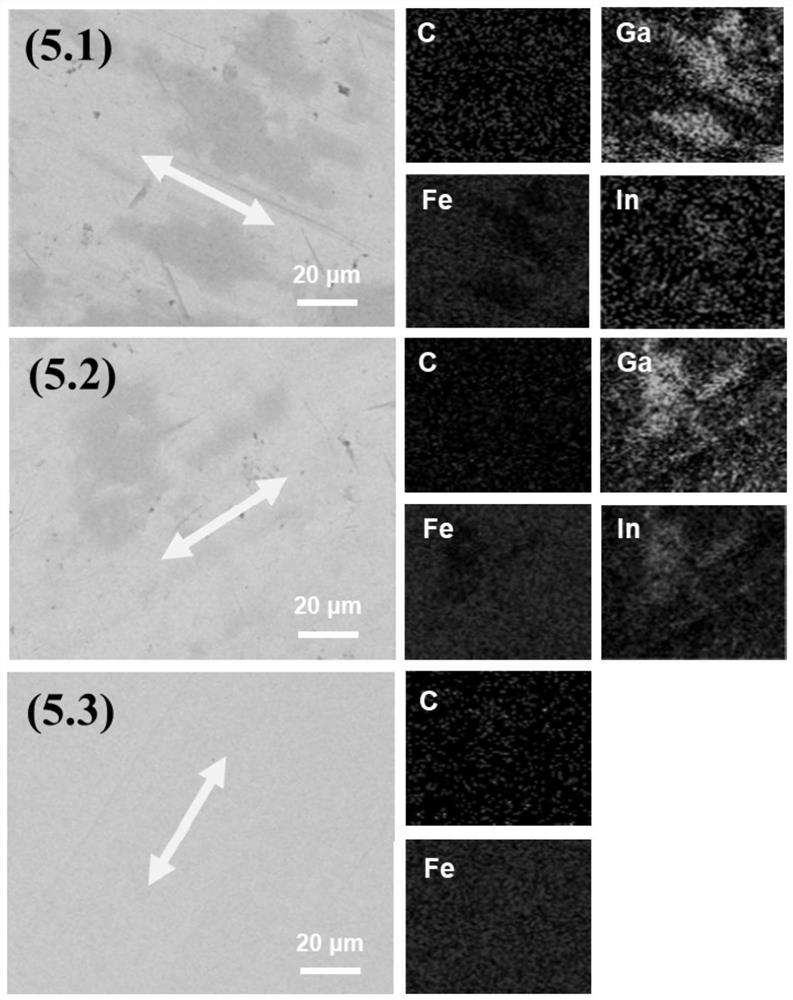

Emitting surface semiconductor LED with nanostructure and its preparing process

InactiveCN101159307AReduce reflectionLarge luminous areaSemiconductor devicesLight reflexManufacturing technology

The invention relates to the technical field of semiconductor photoelectronic device manufacturing, in particular to a semiconductor light emitting diode (LED) with a nanometer light emitting surface. The inventive method comprises growing a dielectric layer (12) and a metal layer (13) on a GaP layer (2) of the conventional LED, and sequentially using the metal layer (13) as a mask to etch the dielectric layer (12) and the parts outside a P type electrode (11) on the upper surface of the GaP layer (2) to obtain the LED with the nanometer light emitting surface. The method also comprises coating a layer of indium tin oxide (ITO) conducting film (10) on the nanometer light emitting surface and the upper surface of the P-type electrode (11), and preparing a P-type electrode (11) with the same structure on the P-type electrode (11) coated with the ITO conducting film (10). The invention reduces light reflex, improves device performance, and can be used in various semiconductor LEDs. Meanwhile, the invention has the advantages of simple process, low cost, and applicability to batch production.

Owner:BEIJING UNIV OF TECH

High-gloss PTFE (polytetrafluoroethylene) anti-drop agent and preparation method thereof

The invention relates to a high-gloss PTFE (polytetrafluoroethylene) anti-drop agent and a preparation method thereof. The preparation method includes: 1), adding a small amount of an emulsified monomer A solution to a PTFE emulsion and performing irradiation treatment on the PTFE emulsion in high energy ray, and grafting a small number of monomers on the surface of PTFE particles; 2), in the absence of oxygen, initiating monomer B to perform polymerization reaction in the treated PTFE emulsion by the aid of an initiator and adding a cross-linking agent at a later stage to form nuclear-shell nano PTFE composite particles with PTFE particles as nuclears and a polymer as a shell; 3), filtering the modified PTFE emulsion and subjecting a filtrate to spray drying to obtain the high-gloss PTFE anti-drop agent. With the method, under the condition that no dispersants or compatibility agents are added, the anti-drop agent can be well-dispersed in thermoplastic resin with good compatibility, and light transmission, glossiness and the like of matrix resin are unaffected by the anti-drop agent dispersed in engineering plastics of PA, PC and the like.

Owner:安徽申嘉聚合物科技有限公司

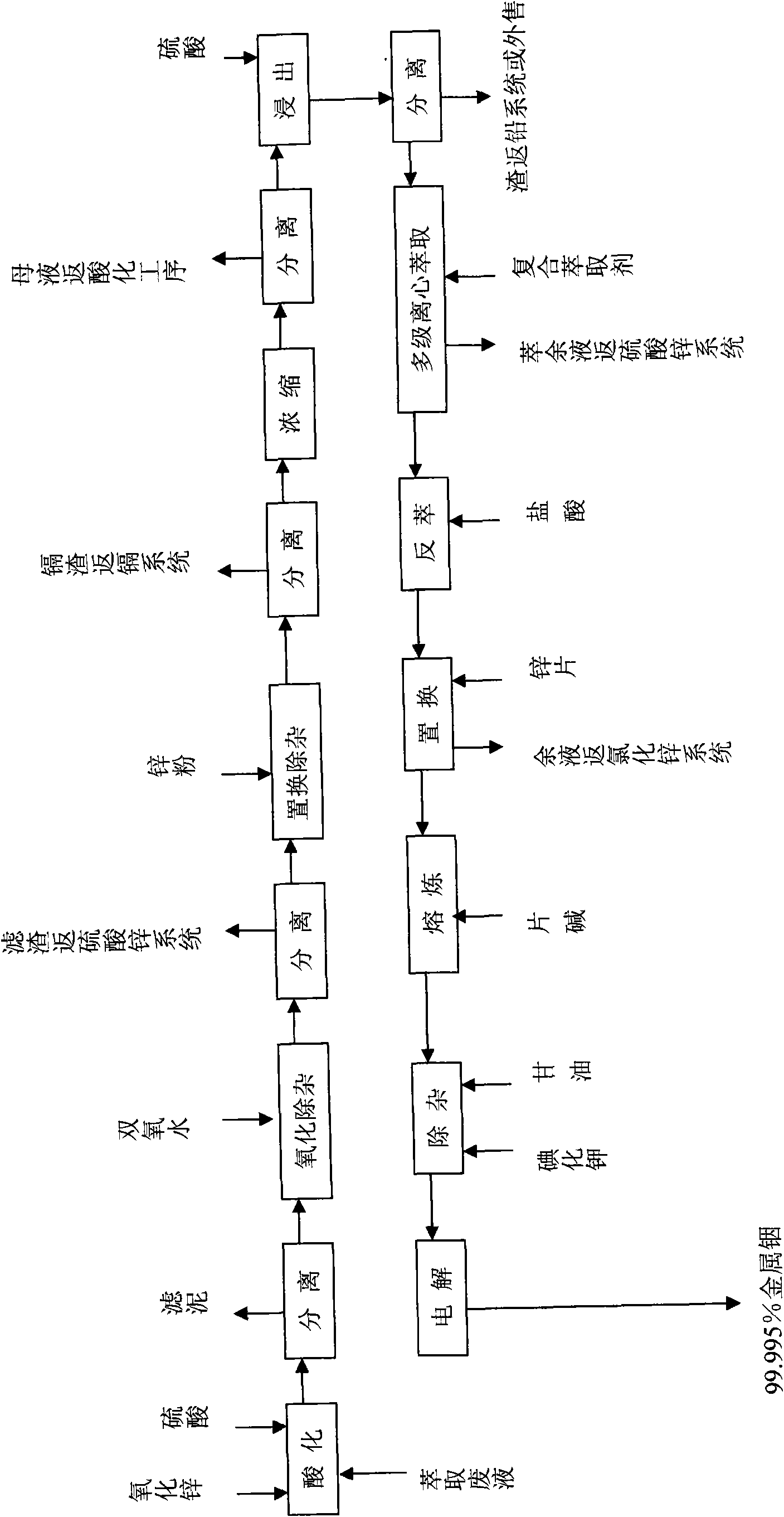

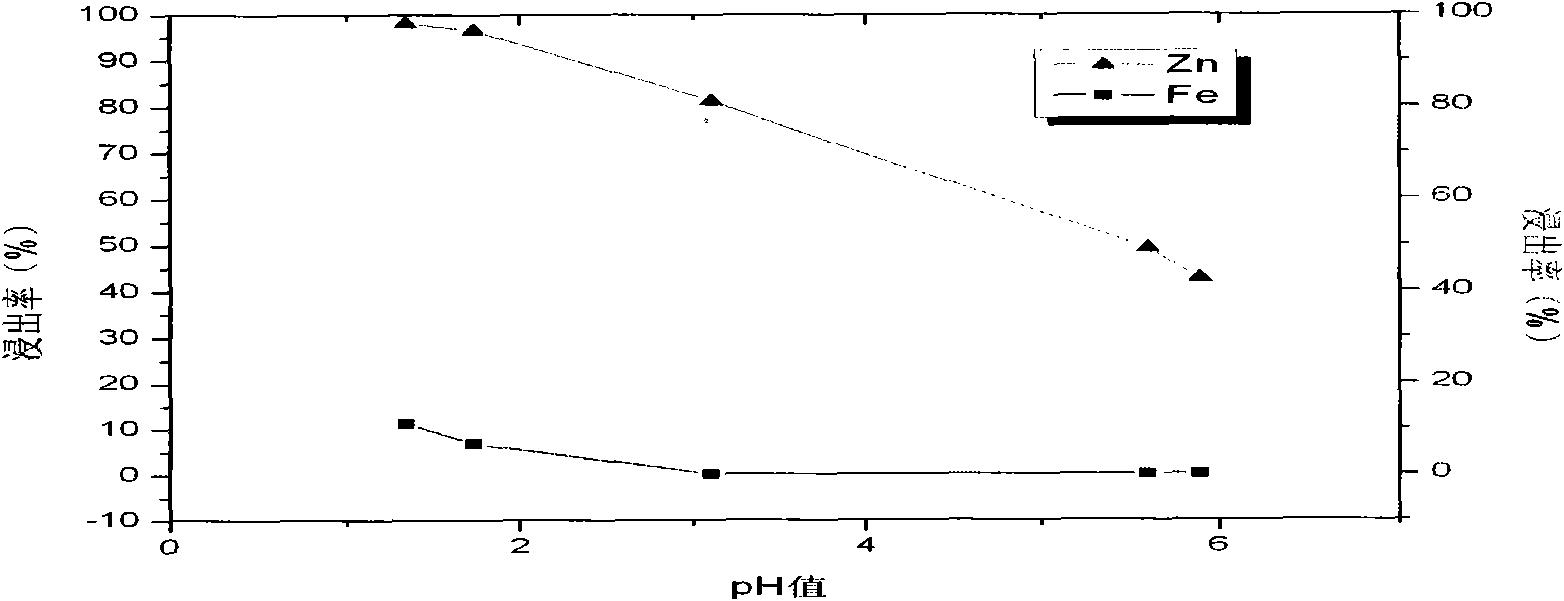

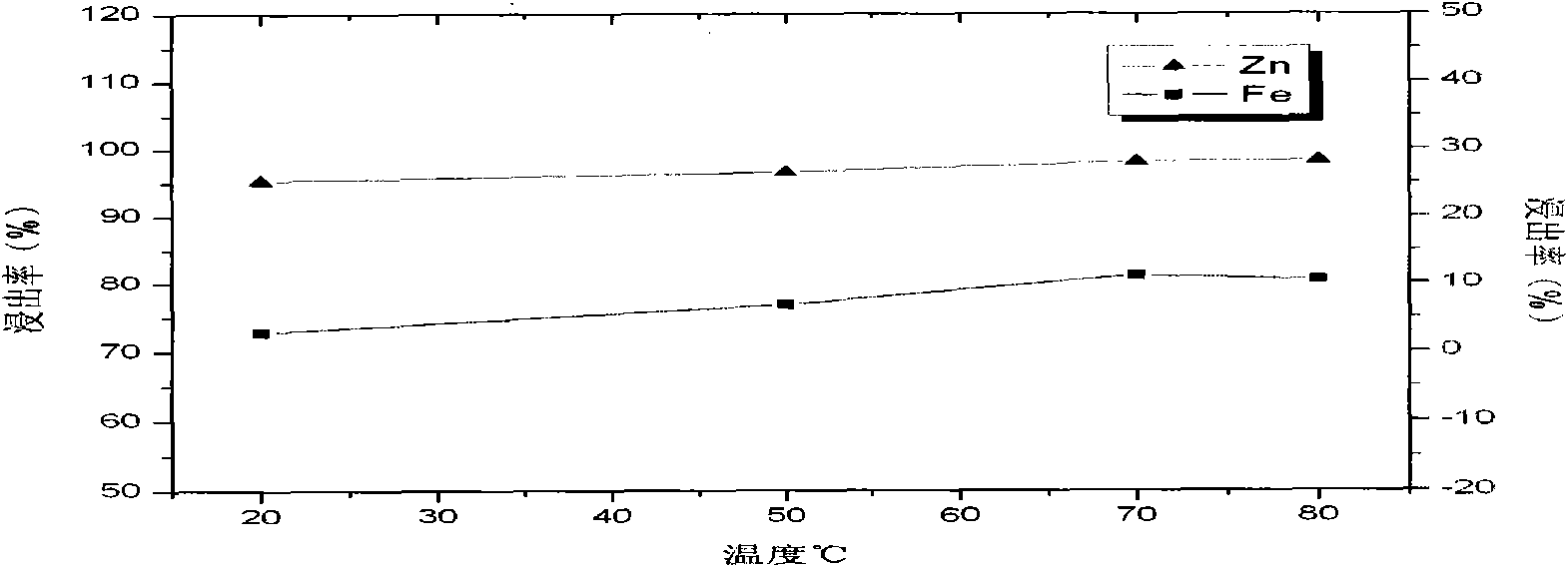

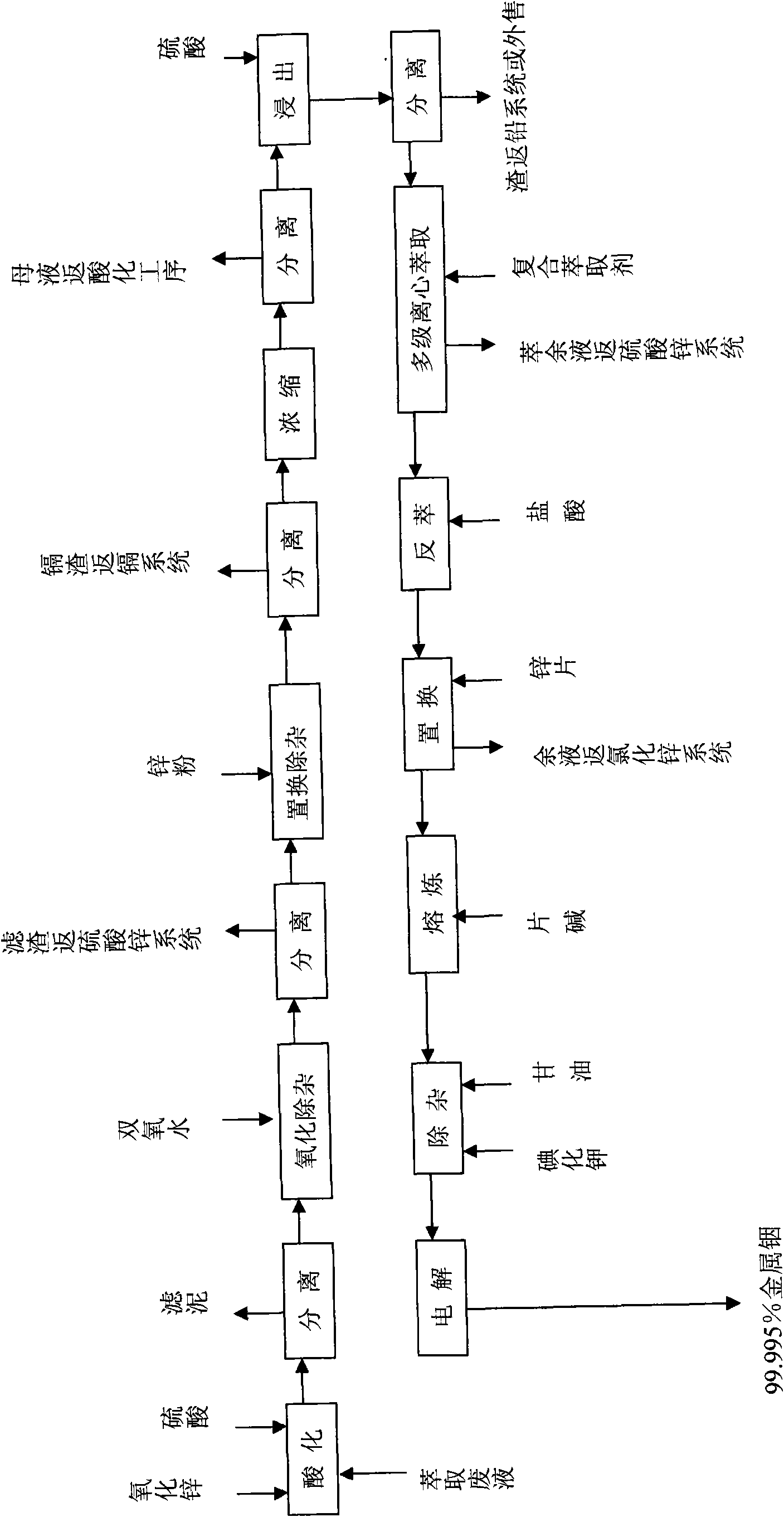

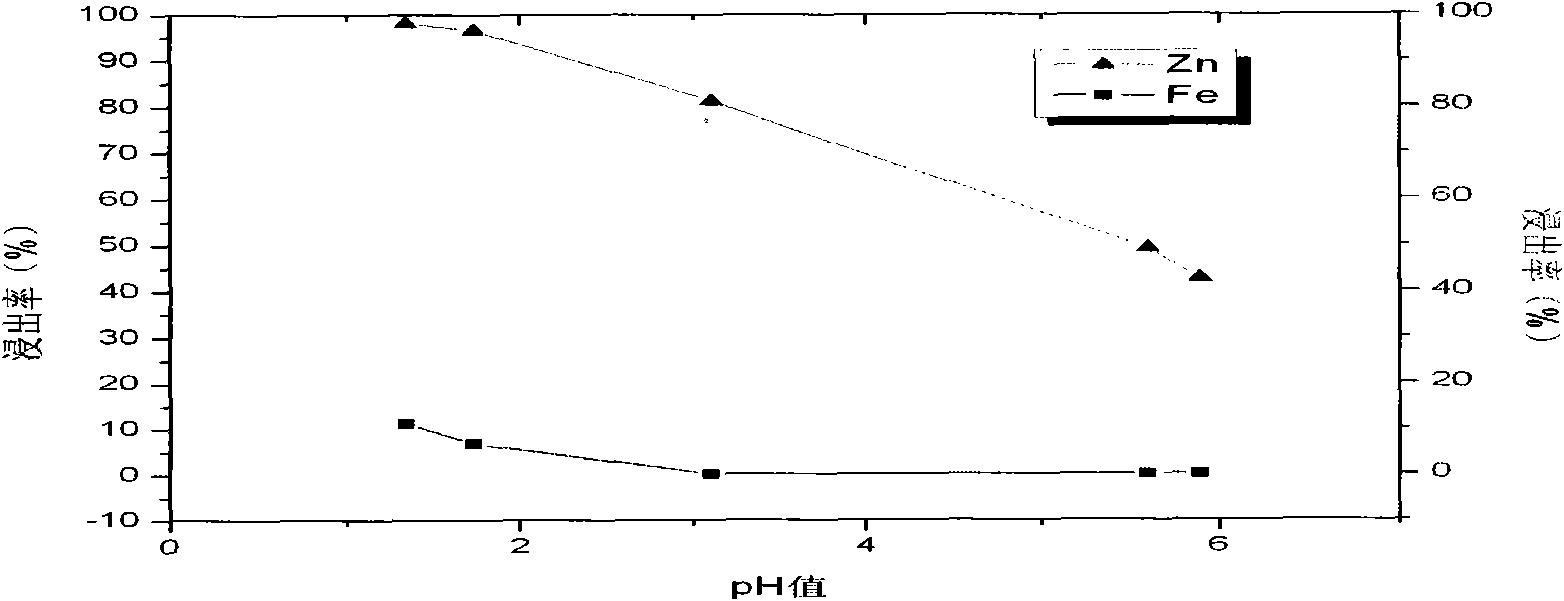

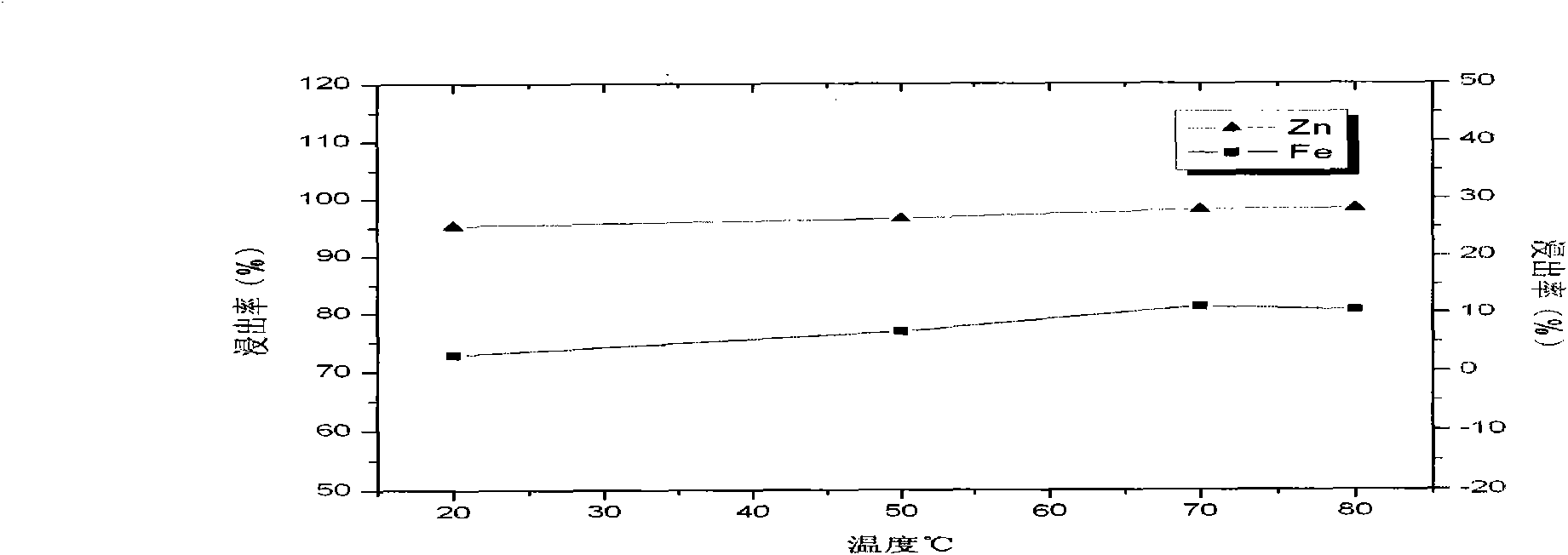

Technological method for extracting indium from zinc oxide generated from waste residue from zinc by hydro-smelting

ActiveCN101597692AInhibition of dissolutionReduce emulsificationProcess efficiency improvementIndiumZinc

The invention relates to the technical field of smelting indium, in particular to relates to a technological method for extracting indium from zinc oxide generated from waste residue from zinc by hydro-smelting. In the process of acidization, the zinc oxide of the invention is acidated by sulphuric acid; after the acid leaching of the zinc oxide, oxyful is used for the deep removal of iron by oxidation in the process of impurity removal of liquid; after the acidization of the zinc oxide, sulphuric acid is used for acidization leaching in a secondary leaching process; the multistage centrifugal extraction which is rich in indium liquid after impurity removal adopts the mixture of Cyanex923 and P204 as a composite extractant; and the back extraction adopts the mixed liquid of 3 mol / L HCL and 2 mol / L ZnC as a back-extractant. The technological method for extracting the indium from the zinc oxide generated from the waste residue from zinc by hydro-smelting has the advantages that the indium smelting production technology parameter and equipment adapt to high altitude and low air pressure environment, the technology is simple, and the operability is high; and the application of the method and the composite extractant of the invention can increase the recovery rate of indium by 10 to 15 percent.

Owner:青海西部铟业有限责任公司

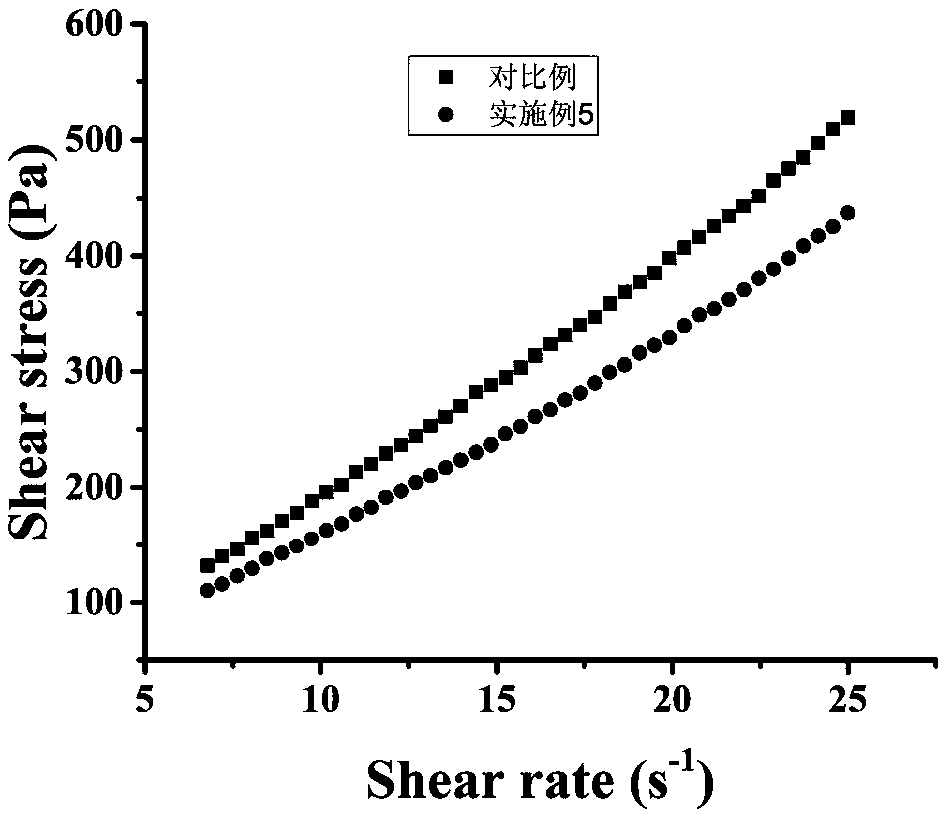

Polycarboxylic-acid concrete efficient water reducer with amide/imide structure and preparation method thereof

ActiveCN104371070AProcess operation is easy to controlPreparation and synthesis are safe and environmentally friendlyImideEnvironmental resistance

The invention provides a polycarboxylic-acid concrete efficient water reducer with an amide / imide structure. The polycarboxylic-acid water reducer prepared by employing the method has the advantages of being simple and easily controllable in technological operation, safe and environment-friendly in preparation synthesis, low in cost, energy-saving, consumption-reducing, substantial in water-reducing dispersing effect, high in storage stability, capable of reducing slurry viscosity under the condition of a low water-binder ratio, and the like. The polycarboxylic-acid water reducer has relatively good adaptability to different kinds of cement under the condition of low doping amount or low water-cement ratio, and helps to solve the problems that the raw material preparation cost of amide / imide type polycarboxylic acids is high, preparation conditions are severe and difficult to control, and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS

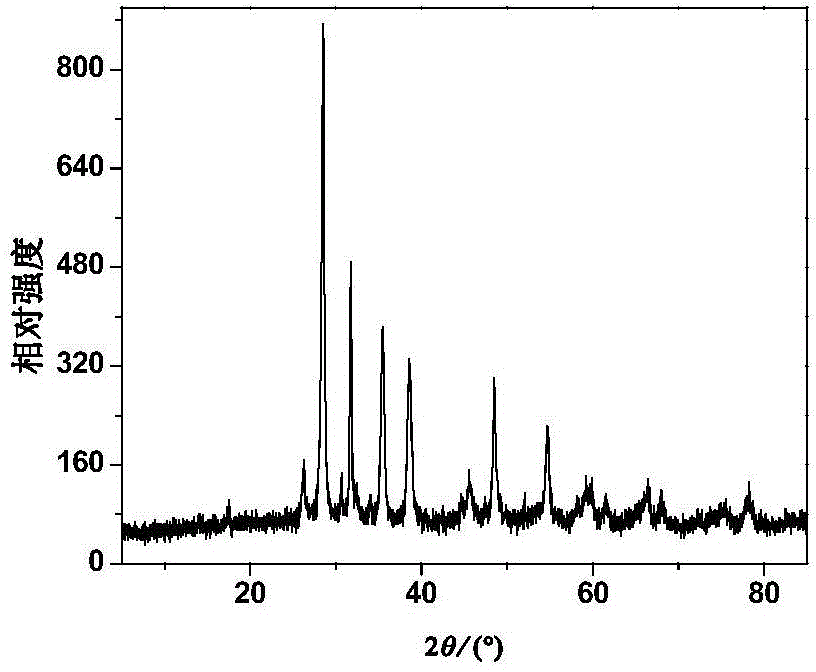

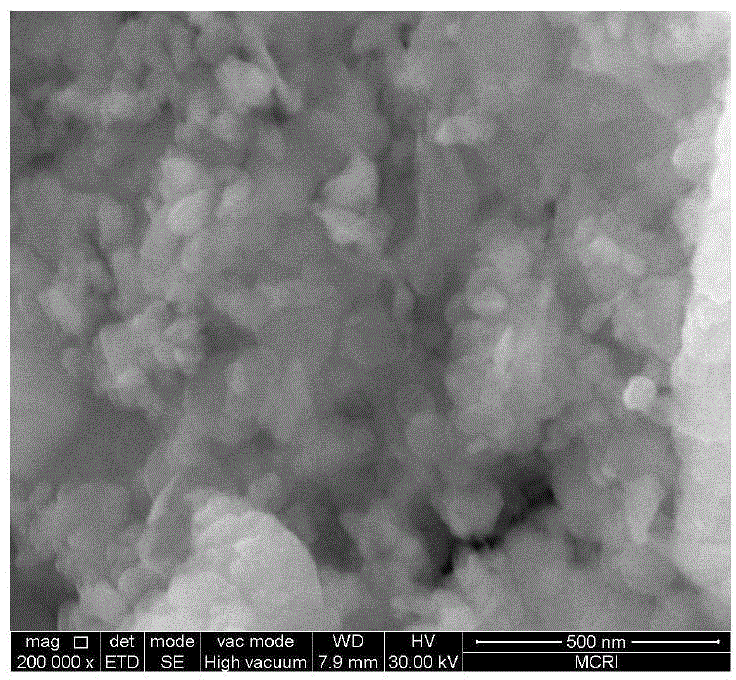

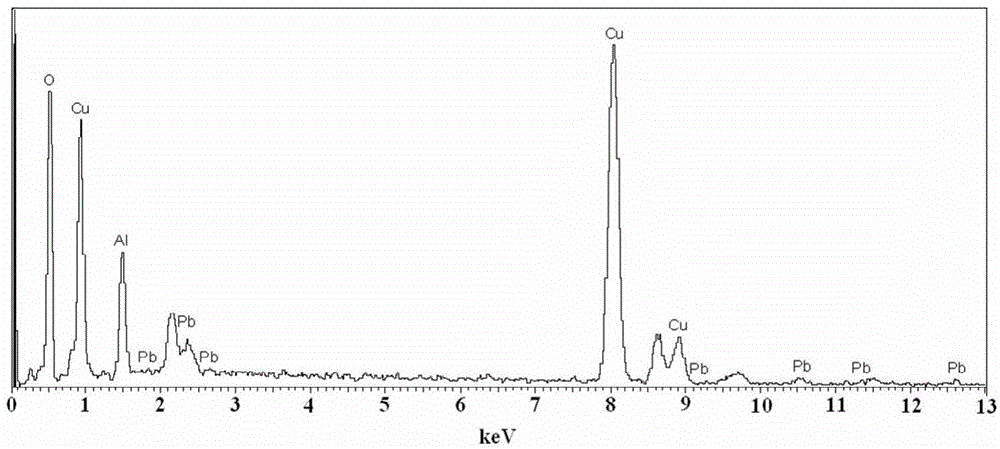

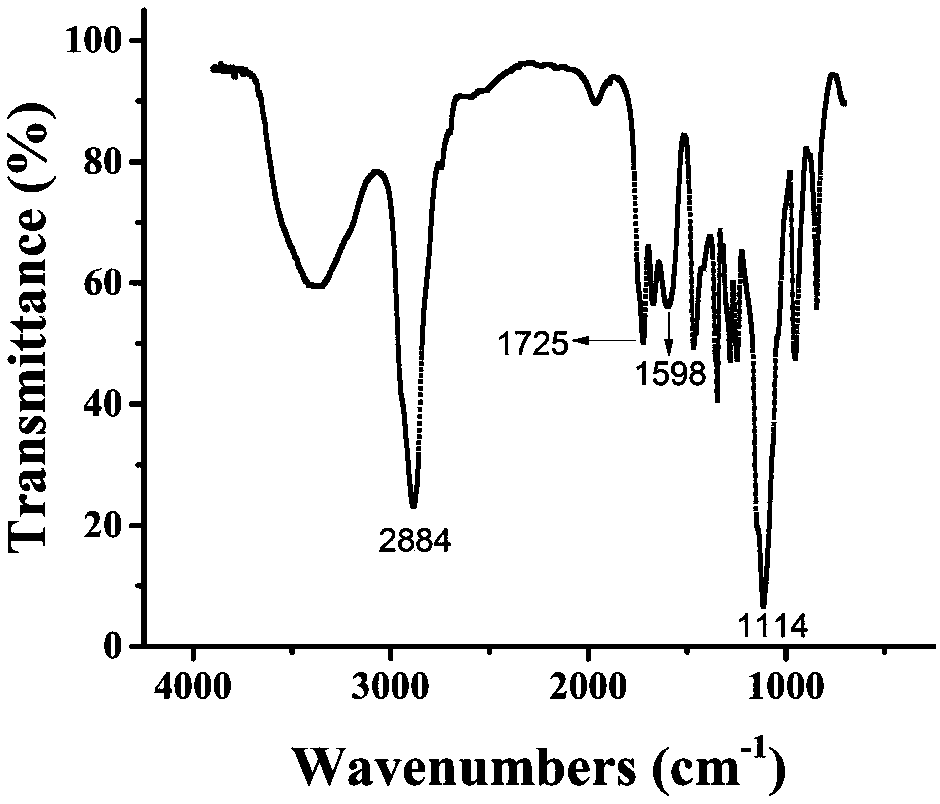

Energetic polyoxide compound super-thermite and preparation method thereof

The invention discloses an energetic polyoxide compound super-thermite. The energetic polyoxide compound super-thermite has the chemical formula represented by n-Al / Ax1Oy1.Bx2Oy2 or n-Al / Ax1Oy1.Bx2Oy2.Cx3Oy3, wherein n represents nanometer super-thermite, Ax1Oy1, Bx2Oy2 and Cx3Oy3 are different metal oxides, A, B and C are selected from Group II, III, IV and V main group metal elements, transition metal elements or lanthanide elements, x and y are positive integers and meet chemically reasonable values and the particle size of nanometer aluminum powder is 20-100nm. The energetic polyoxide compound super-thermite is prepared by virtue of a room-temperature solid-phase reaction-ultrasonic oscillation composite method which has the advantages of being low in cost, high in yield, simple and feasible in preparation process, environment friendly, free of pollution and the like and is suitable for pilot-plant-scale and large-scale popularization and production. The compound super-thermite as a combustion catalyst, which is prepared by the method has excellent catalytic effect on the combustion of a double-base propellant and is an efficient combustion catalyst.

Owner:XIAN MODERN CHEM RES INST

Amide/imide structure polycarboxylate superplasticizer and preparation method thereof

ActiveCN107652405AProcess operation is easy to controlThe synthesis process is safe and environmentally friendlyImideSuperplasticizer

The invention discloses an amide / imide structure polycarboxylate superplasticizer and a preparation method thereof. The amide / imide structure polycarboxylate superplasticizer is synthesized by amidation / imidization of amine-terminated polyether to obtain polymerizable polyether amine, and then copolymerization reaction with active monomers. The preparation method of the polycarboxylate superplasticizer provided by the invention has the advantages of simple and easily controllable technological operation, safe and environment-friendly synthetic process, low cost, energy saving and consumption reduction. Also the obtained amide / imide structure polycarboxylate superplasticizer has the advantages of high water-reducing rate, good flowing retention performance, long storage period, significantreduction of slurry viscosity under a low water-binder ratio and the like, thus solving the problems of great difficulty, difficultly available raw materials, many side reactions, harsh conditions, high cost and the like in the amide / imide polycarboxylate synthesis process.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

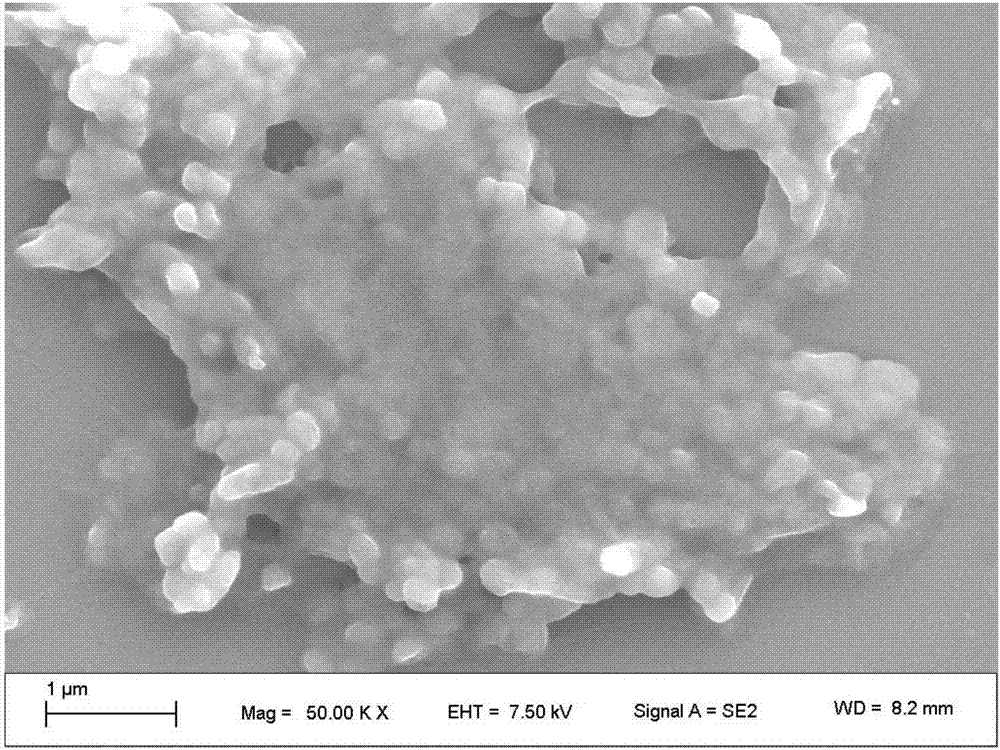

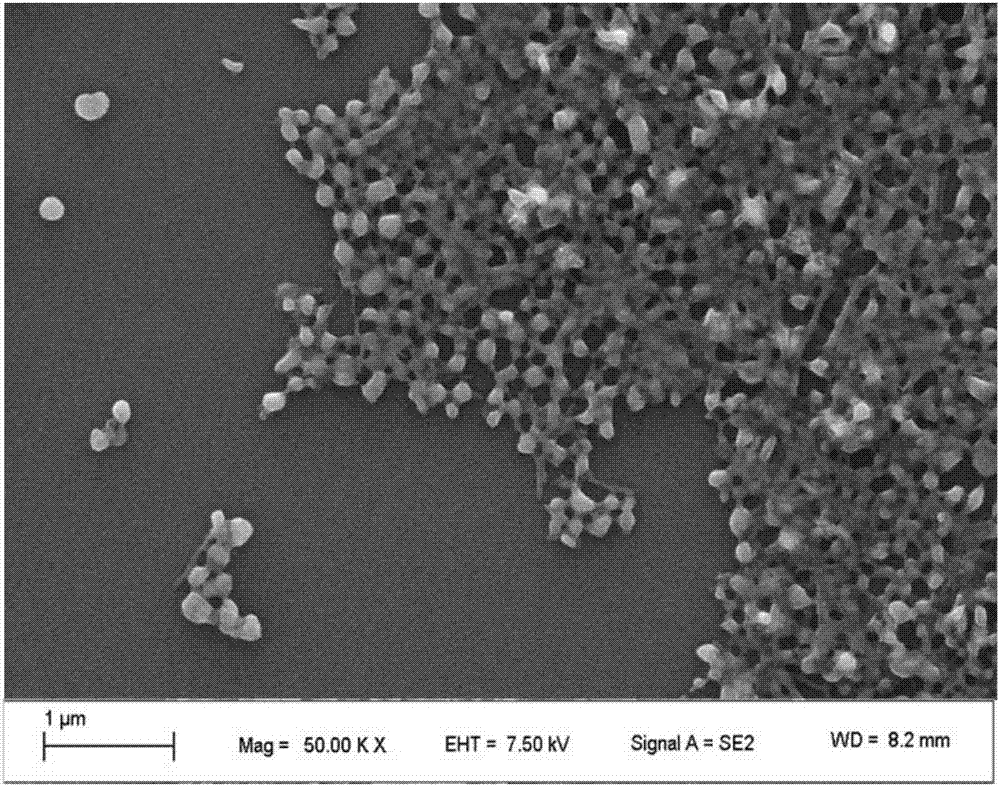

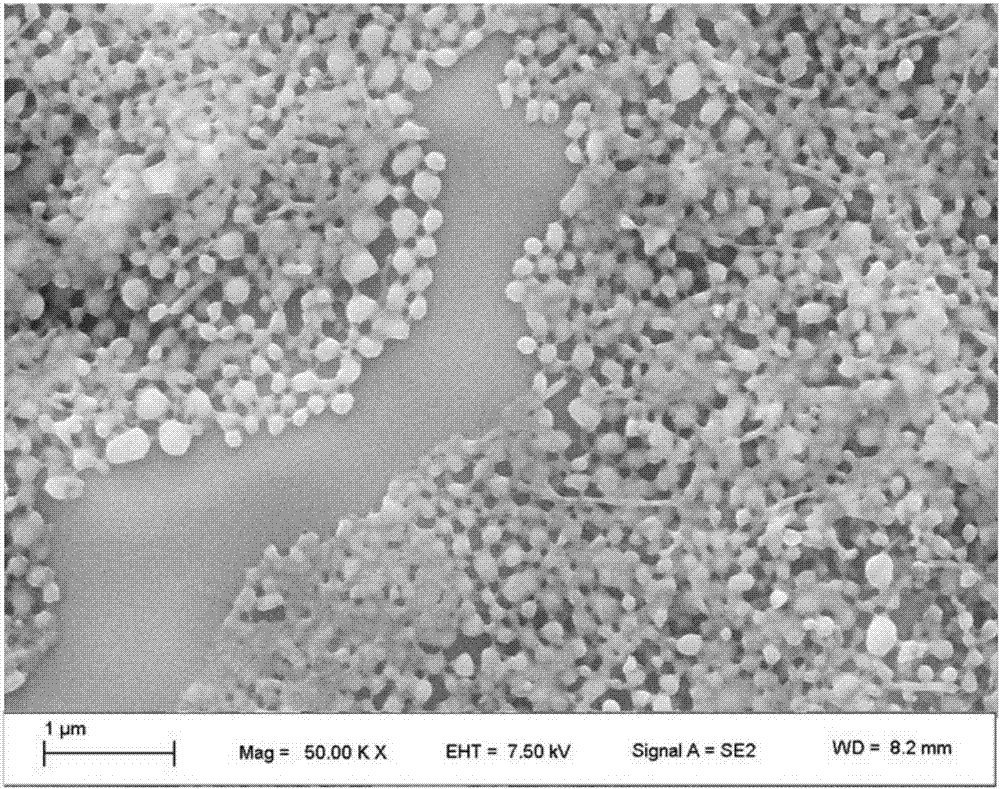

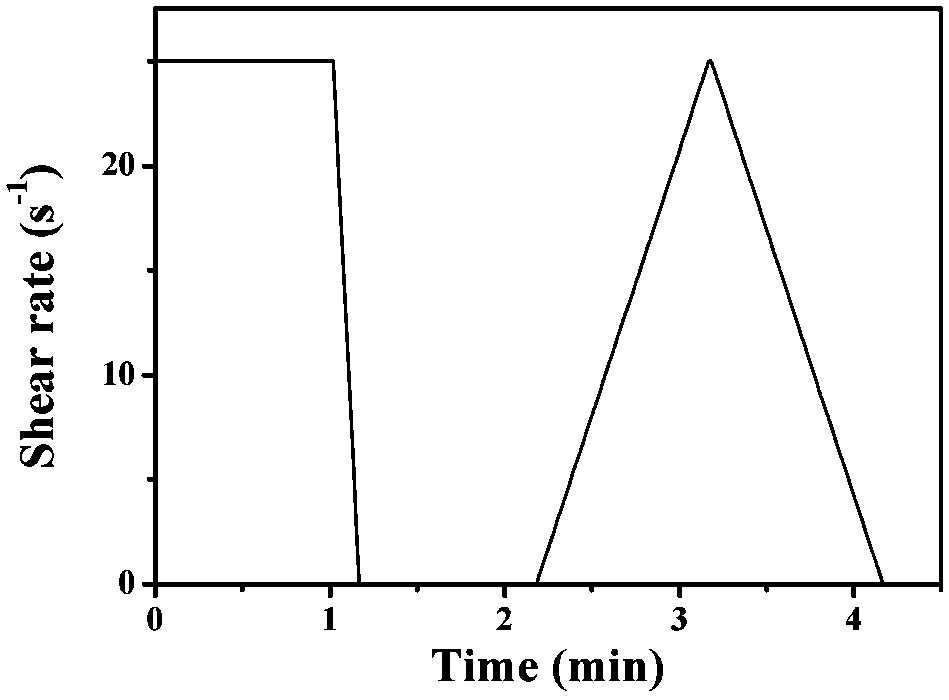

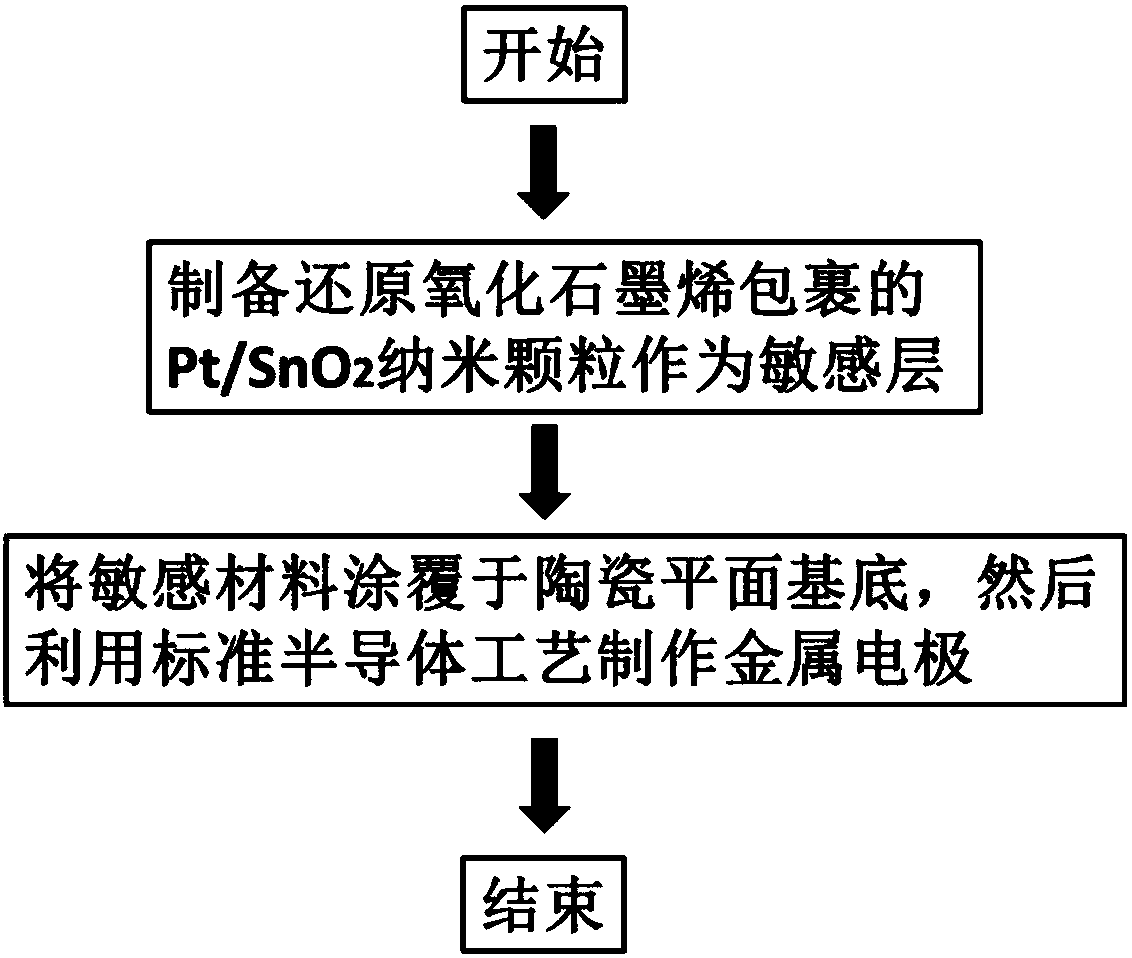

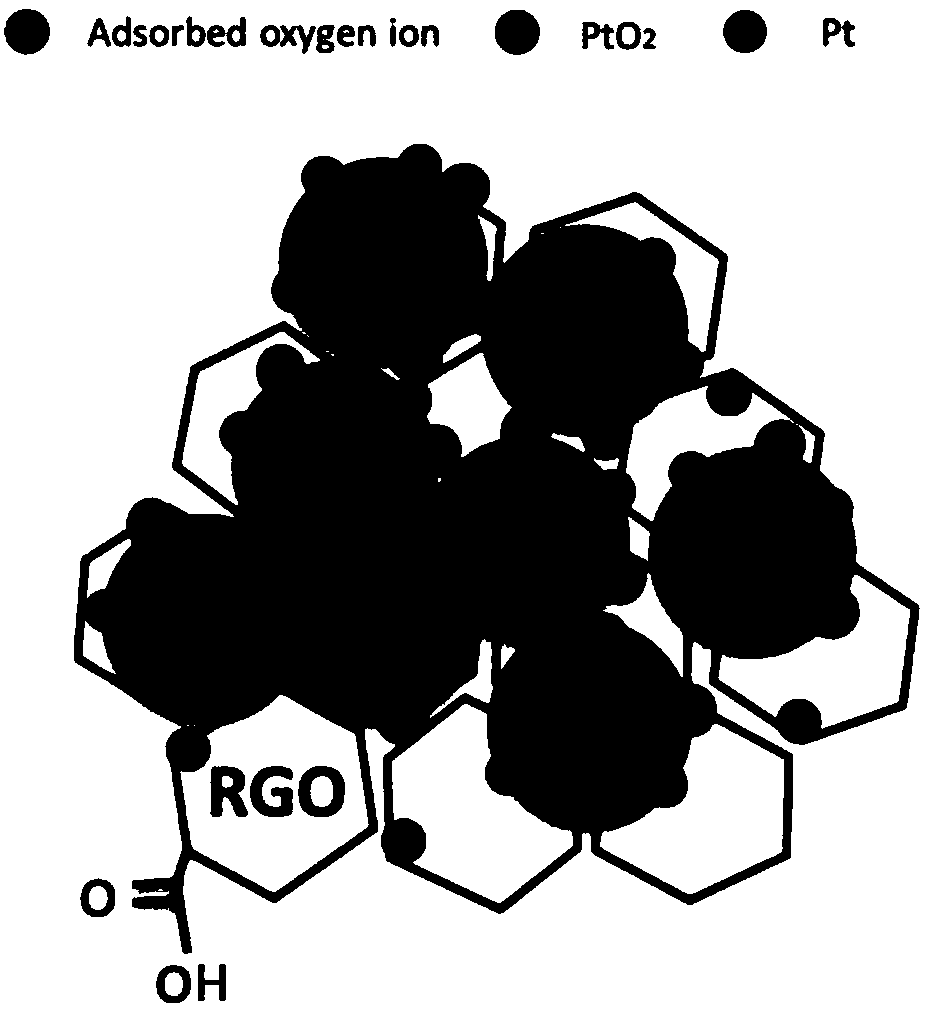

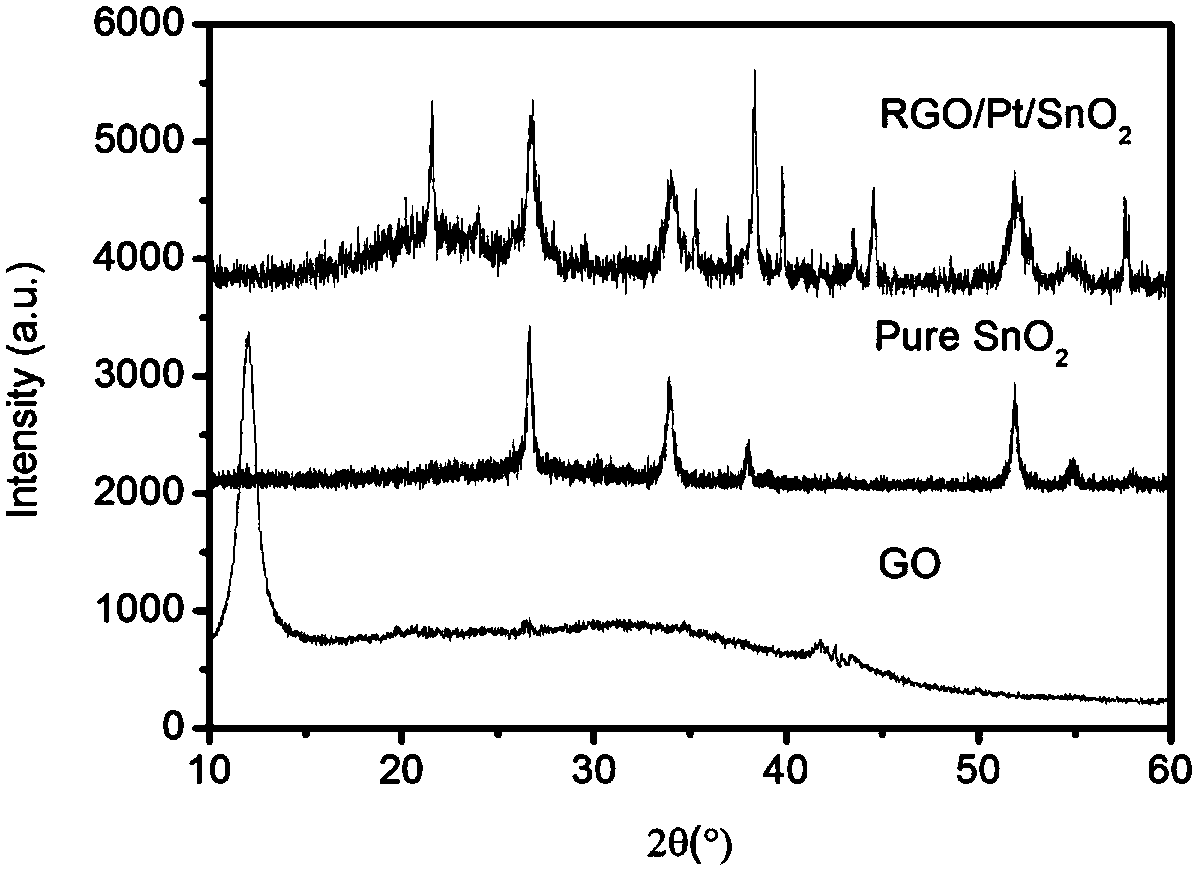

Reduced graphene oxide coated platinum/stannic oxide nano-particle cluster gas sensor and preparation method thereof

ActiveCN108318510ALower grain boundary barrierHigh specific surface areaMaterial analysis using radiation diffractionMaterial analysis by measuring secondary emissionTin dioxidePlatinum

The invention relates to a reduced graphene oxide coated platinum / stannic oxide nano-particle cluster gas sensor and a preparation method thereof. The structure of a composite is like a core-shell composited structure, wherein the platinum atoms are evenly distributed on the surface of stannic oxide to form a core of a nano-particle cluster, and the surface of the whole core is coated with reducedgraphene oxide as a shell. Aiming at the problems of low sensitivity, high working temperature, high production cost and complicated preparation process in the prior art, the invention provides the reduced graphene oxide coated platinum / stannic oxide nano-particle cluster gas sensor and the preparation method thereof. The prepared methyl alcohol sensor can detect at high sensitivity and at the temperature of 110 DEG C, can respond fast, and is high in stability at the same time; in addition, the preparation method is simple and controllable, the production cost is low, the preparation methodis easy to product on the large scale, and the application prospect is quite excellent.

Owner:SHANDONG UNIV

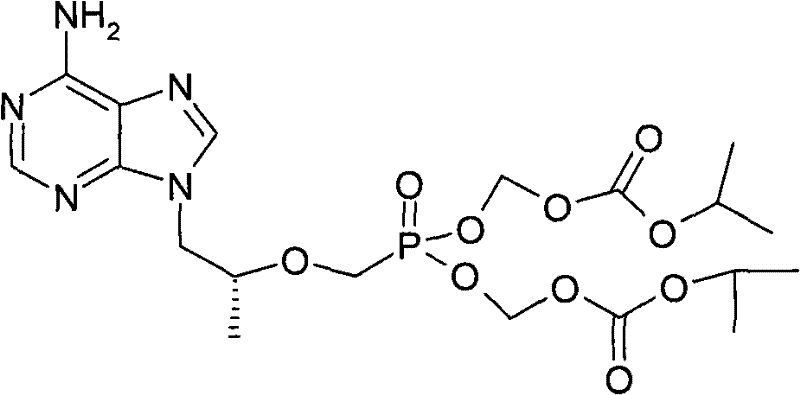

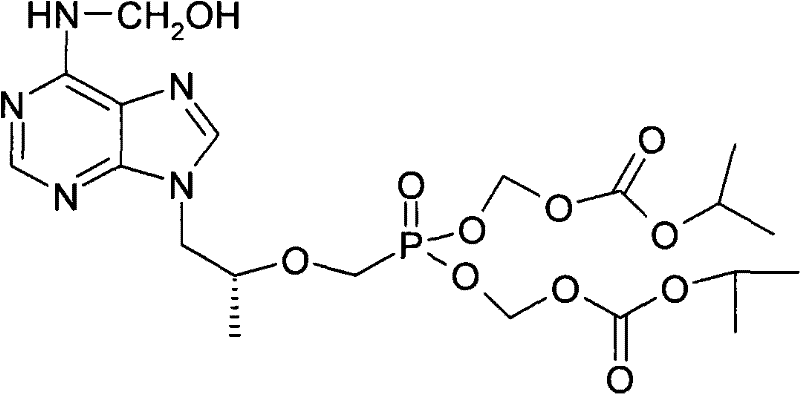

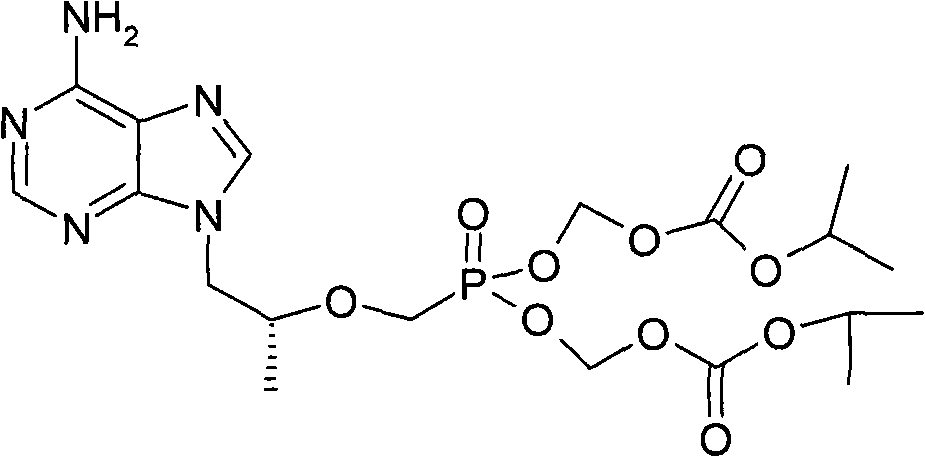

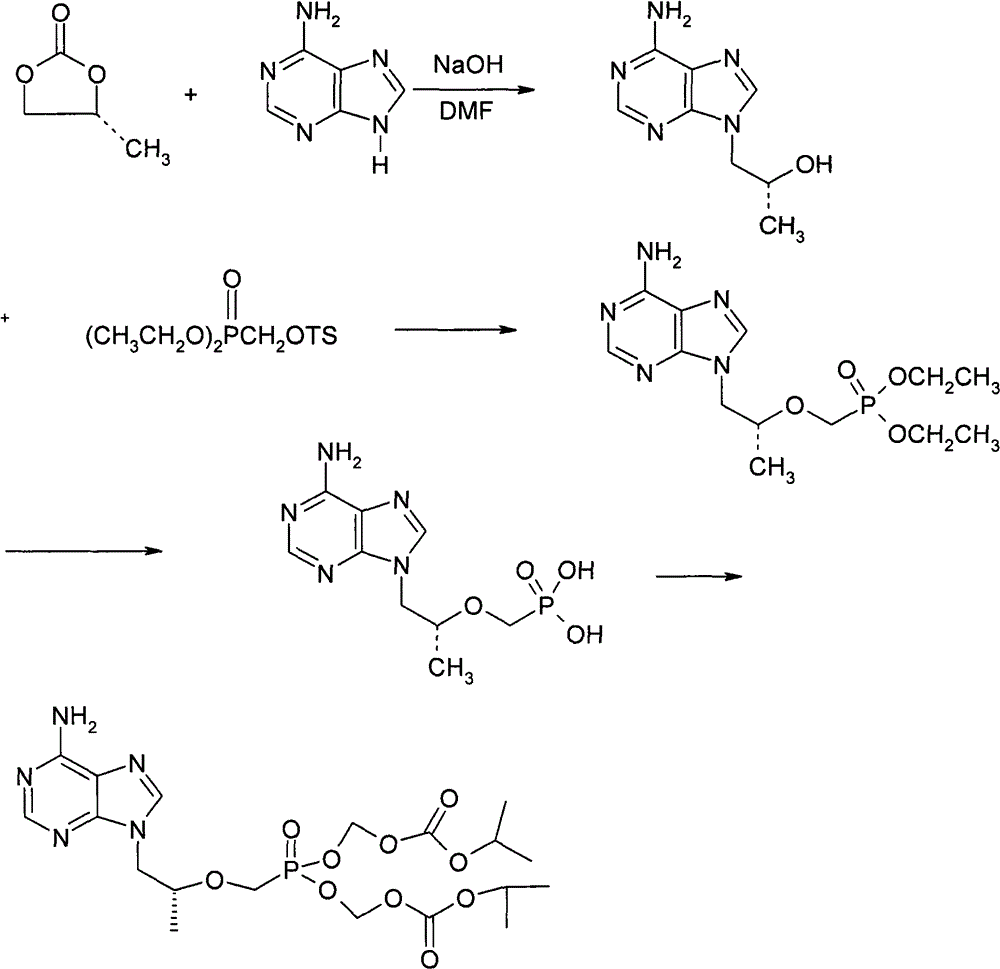

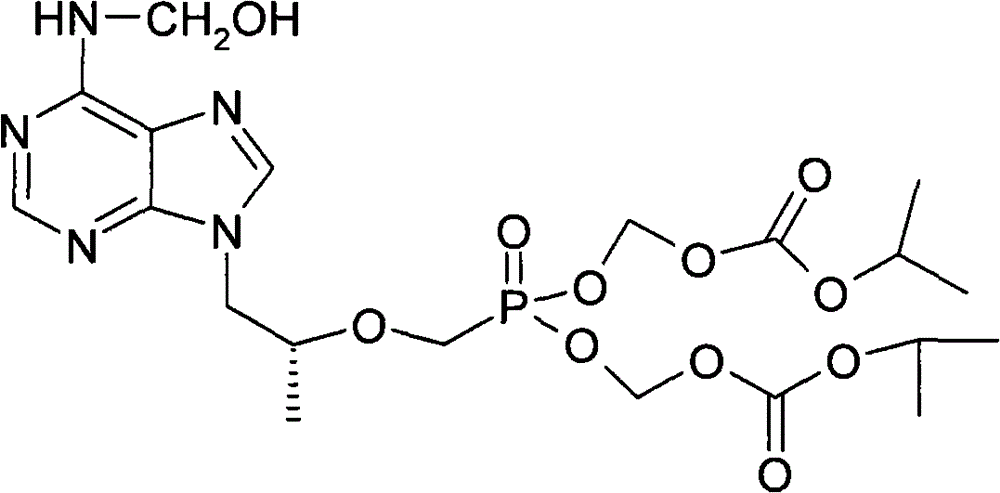

Method for preparing (R)-9-(2-phosphorylmethoxypropyl)adenyl-di(isopropoxycarbonylmethyl)ester

ActiveCN102453055ASources are cheap and readily availableProcess operation is easy to controlGroup 5/15 element organic compoundsSynthesis methodsAcetonitrile

The invention discloses a novel synthesis method of (R)-9-(2-phosphorylmethoxypropyl)adenyl-di(isopropoxycarbonylmethyl)ester, which comprises the following steps; after tenofovir used as a raw material and triethylamine are salified in acetonitrile, evaporating to remove acetonitrile, remaining triethylamine and water in the tenofovir triethylamine salt, and carrying out condensation reaction with chloromethylisopropyl carbonate to obtain the (R)-9-(2-phosphorylmethoxypropyl)adenyl-di(isopropoxycarbonylmethyl)ester. The method disclosed by the invention has the advantages of cheap and accessible raw material, easily controlled technological operation, high yield and low cost, and is suitable for industrial production.

Owner:YANCHENG DESANO PHARMA CO LTD +1

Autoclaved fly ash brick for construction and manufacturing method thereof

The invention discloses an autoclaved fly ash brick for construction, which is prepared from the following raw materials by weight in mixture ratio: 13 to 17 of boiler slag, 13 to 17 of fly ash, 8 to 12 of granolithic, 18 to 22 of carbide slag and 38 to 42 of mountain flour. When the fly ash brick is prepared, the boiler slag, the fly ash, the granolithic, the carbide slag and the mountain flour which are ground into a powder shape are mixed evenly according to the mixture ratio by weight of 13 to 17:13 to 17:8 to 12:18 to 22:38 to 42, water is added, and a mixed material with the water content of 10 to 15wt% is prepared and is autoclaved and cured to prepare a finished product after the mixed material is pressed and molded. The invention has simple technological formula, easy control of the technological operation and stable product quality and is a novel energy-saving environment-friendly process.

Owner:GAOMI FURI BUILDING MATERIALS

Extraction method for sweet potato dietary fiber

InactiveCN103637220AIncrease added valueAvoid environmental pollutionInorganic compound food ingredientsFood shapingBiotechnologySweet potato - dietary

The invention relates to an extraction method for sweet potato dietary fiber. The method includes: selecting starch extracted sweet potato residue as the raw material, conducting soaking by clear water, adding water and smashing the material into a sweet potato residue slurry; adding a sodium hydroxide solution into the sweet potato residue slurry to dissolve out the protein and fat therein; performing filtration, adding a hydrogen peroxide solution into the sweet potato residue subjected to alkali treatment to remove sweet potato residue polyphenol; conducting filtration, then adding a hydrochloric acid solution into the sweet potato residue polyphenol removed sweet potato residue to dissolve out the starch in the sweet potato residue; performing filtration, then flushing the acid treated sweet potato residue by distilled water to neutral, thus obtaining a neutral sweet potato insoluble; and carrying out drying and crushing, thus obtaining sweet potato dietary fiber. The method provided by the invention has the advantages of reasonable process, strong operability, high dietary fiber yield and purity, and can be used for large scale industrialized production.

Owner:威海市桢昊生物技术有限公司

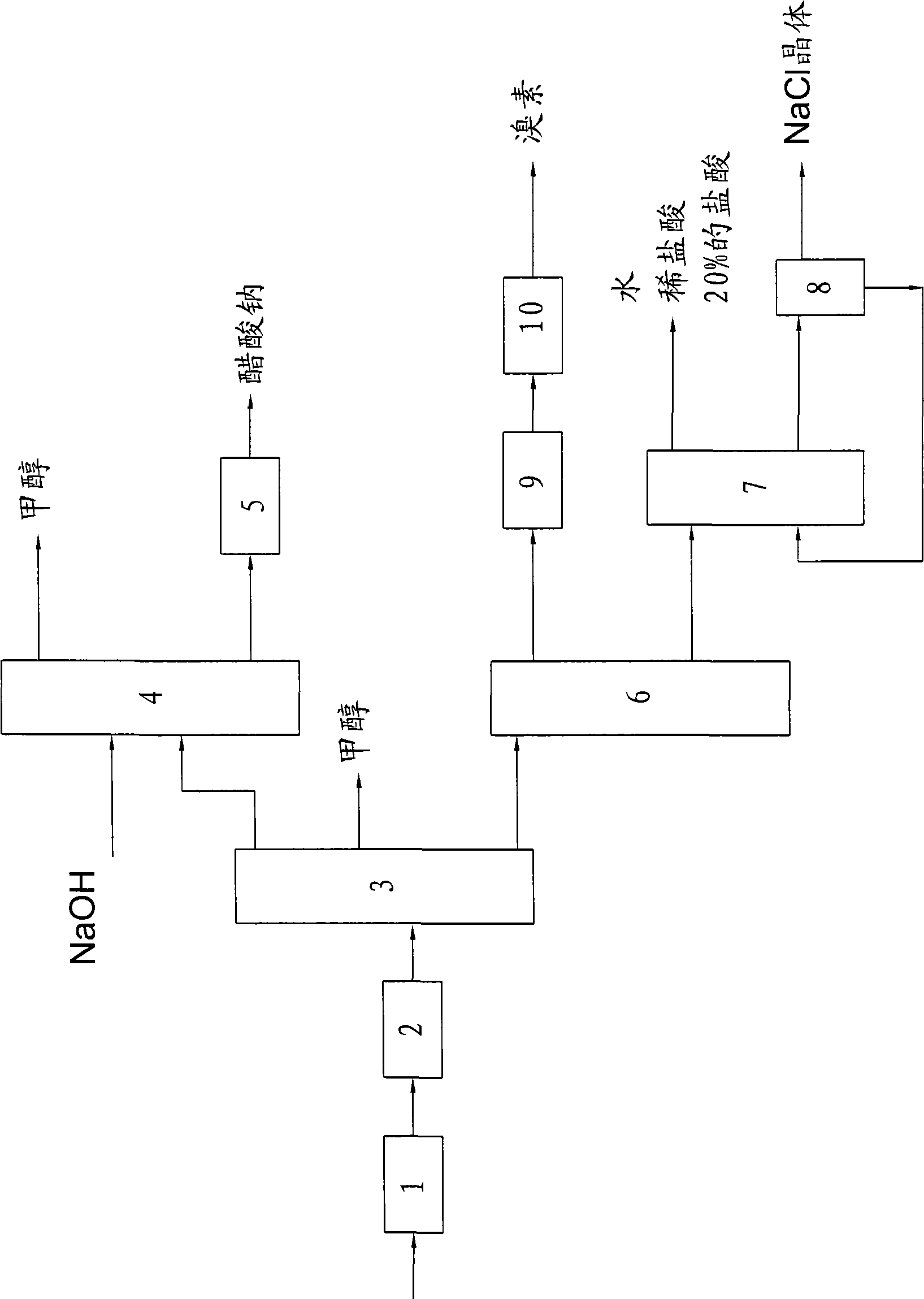

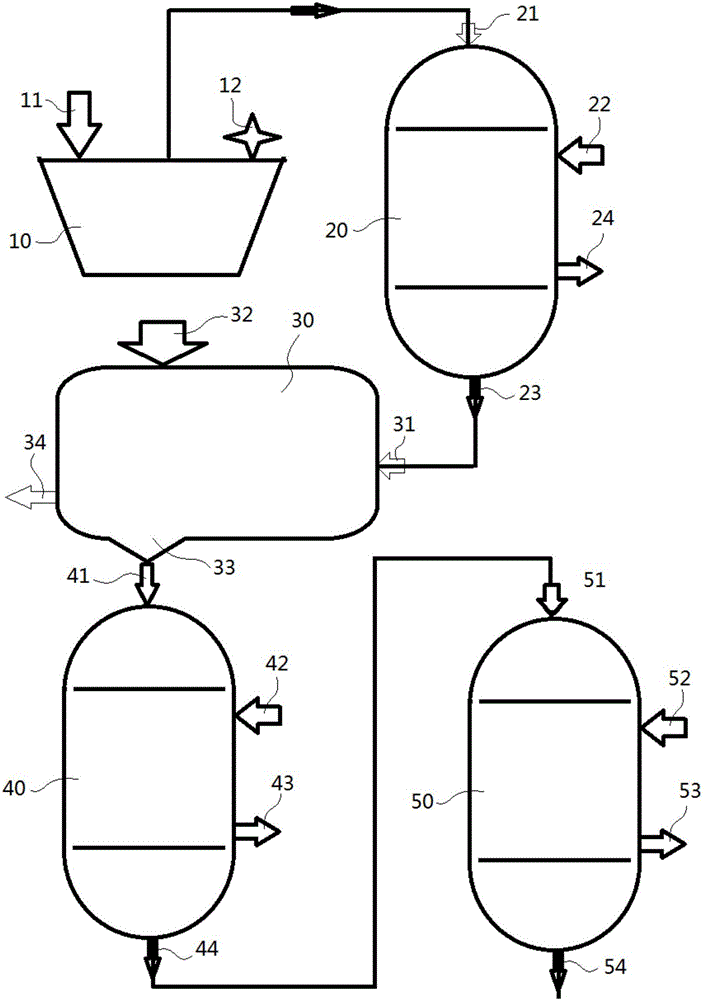

Comprehensive extraction and processing method of industrial wastewater

InactiveCN101544439AReduce energy consumptionIncrease valueChlorine/hydrogen-chlorideMultistage water/sewage treatmentOrganic acidIndustrial effluent

The present invention relates to a comprehensive processing technique of industrial wastewater, and specifically to the comprehensive extraction and processing method of industrial wastewater, wherein the industrial wastewater simultaneously comprises bromine, low molecular organic acid and low molecular alcohol. The invention is characterized in that the technique comprises the following steps: 1) oxidizing; 2) esterifying, 3) rectifying; 4) hydrolyzing and rectifying; 5) rectifying the bromine; 6) refining the bromine; 7) rectifying the hydrochloric acid; and 8) crystallizing the sodium chloride. Compared with the prior art, the method and technique of the invention have the advantages of easy control, energy consumption saving, obtainment of industrial product standard of each recycling object quality, high value, considerable economic benefit, basic realization of zero discharge of wastewater, and total obtainment of environmental requirement.

Owner:党葆和

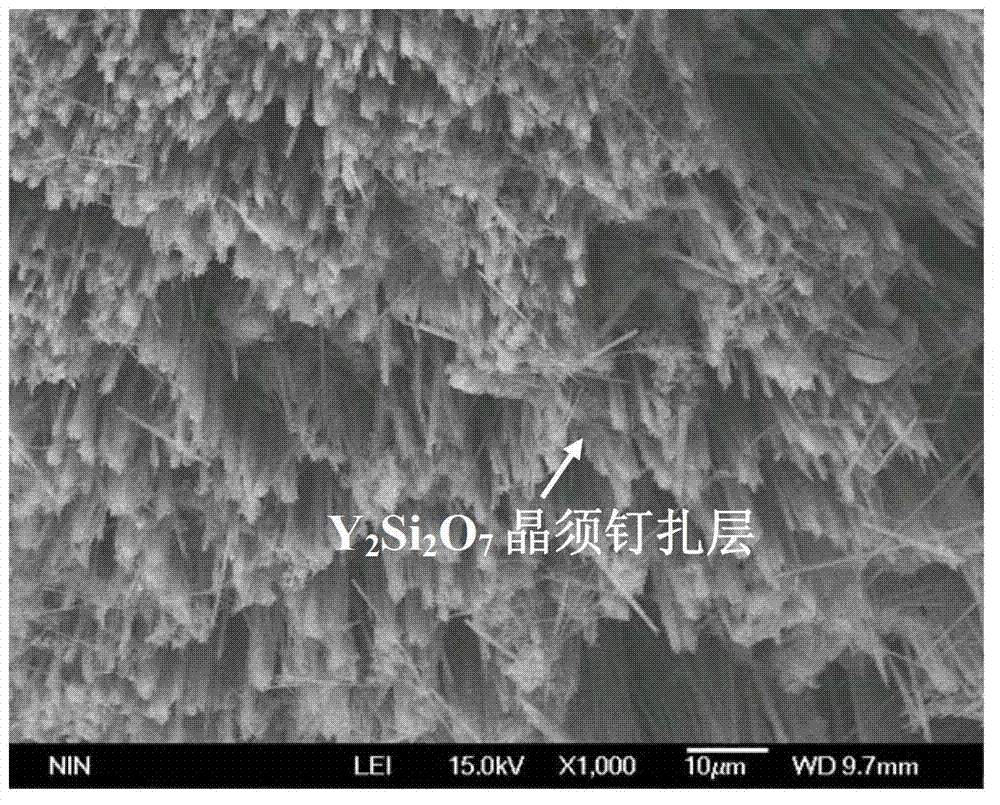

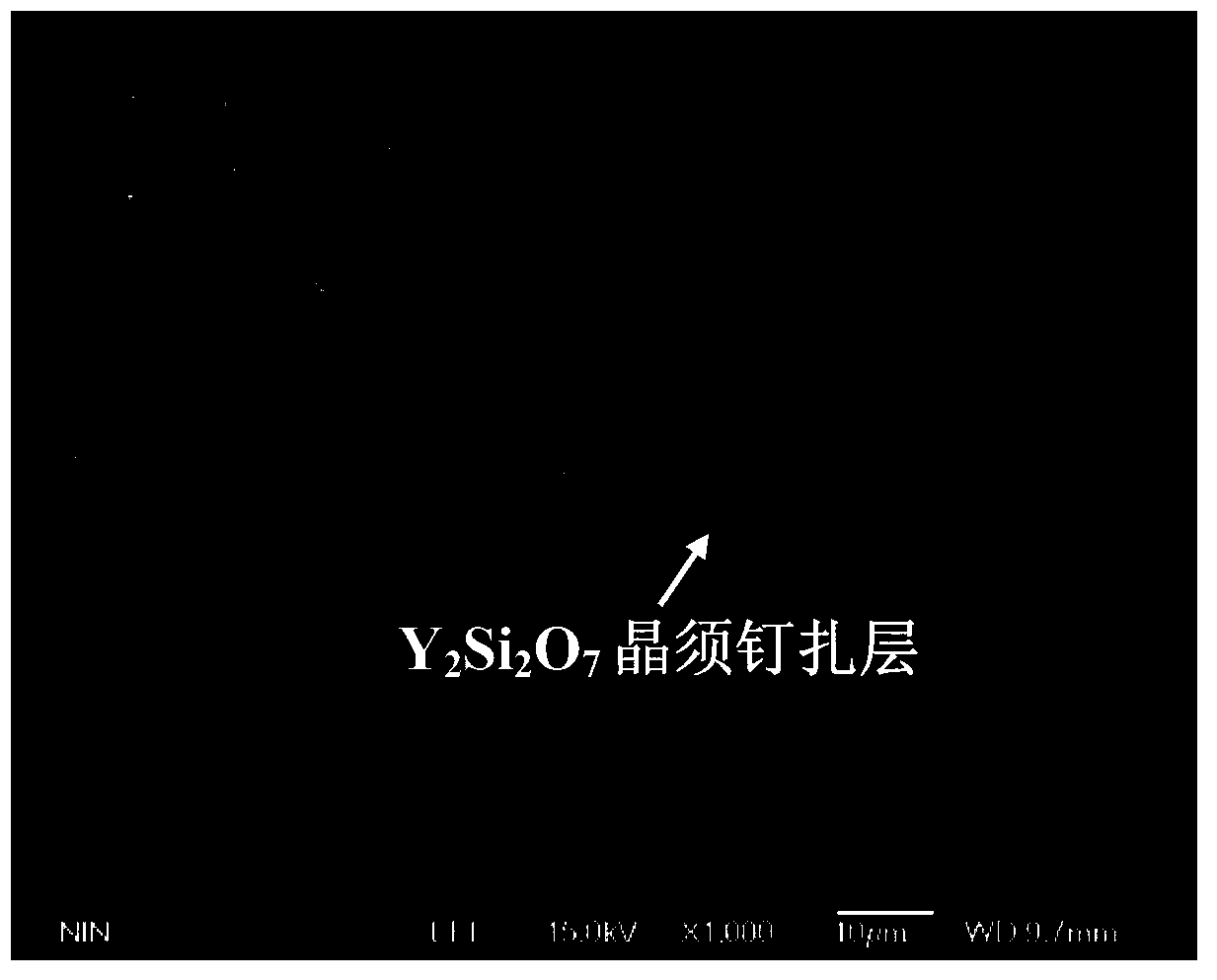

Method for preparing Y2Si2O7 whisker-toughened mullite composite coating

ActiveCN102924108AControllable process operationReduce the temperatureElectrophoretic depositionActive agent

The invention relates to a method for preparing a Y2Si2O7 whisker-toughened mullite composite coating. The method comprises the following steps: preparing a SiC porous internal coating on the matrix surface of a C / C composite material through an embedding method, preparing Y2Si2O7 whiskers, and then performing surface modification to the Y2Si2O7 whiskers with a composite surface active agent to obtain a mixed liquor; and performing ultrasonic electrophoretic selective assembly deposition to the C / C composite material prepared with the SiC porous internal coating and the mixed liquor to obtain a Y2Si2O7 whisker pinning layer, and finally preparing the Y2Si2O7 whisker-toughened mullite composite coating through a hydrothermal electrophoretic deposition method. Compared with other coatings, the prepared Y2Si2O7 whisker-toughened mullite composite coating can effectively increase the oxidation-resistance temperature, can realize the anti-oxidation protection of 400 hours for the C / C composite material under the condition of dynamic brush of high temperature (1700 DEG C) gas, and the oxidation loss rate is lower than 0.77 percent.

Owner:杨洁如

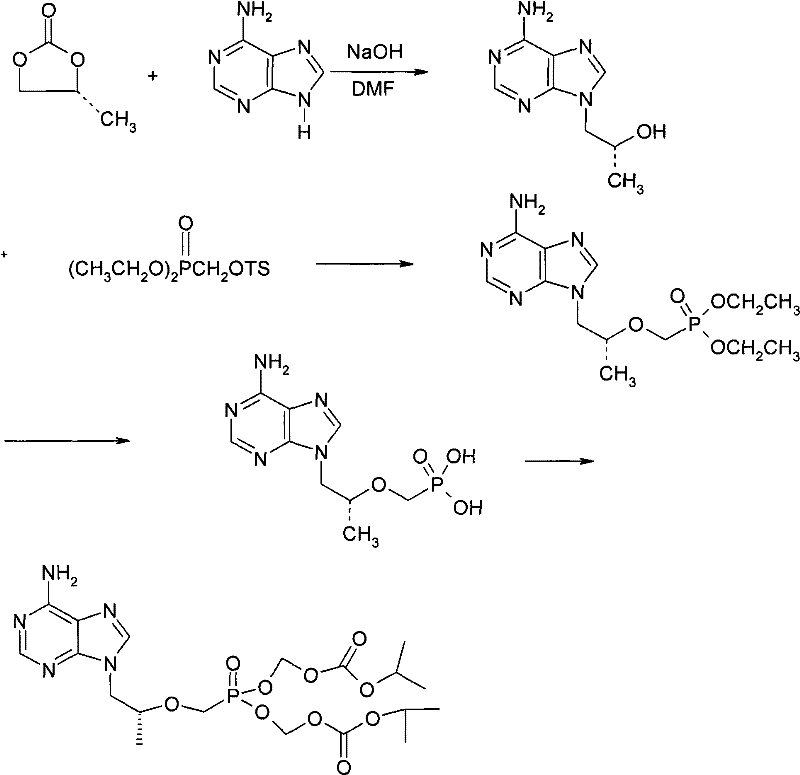

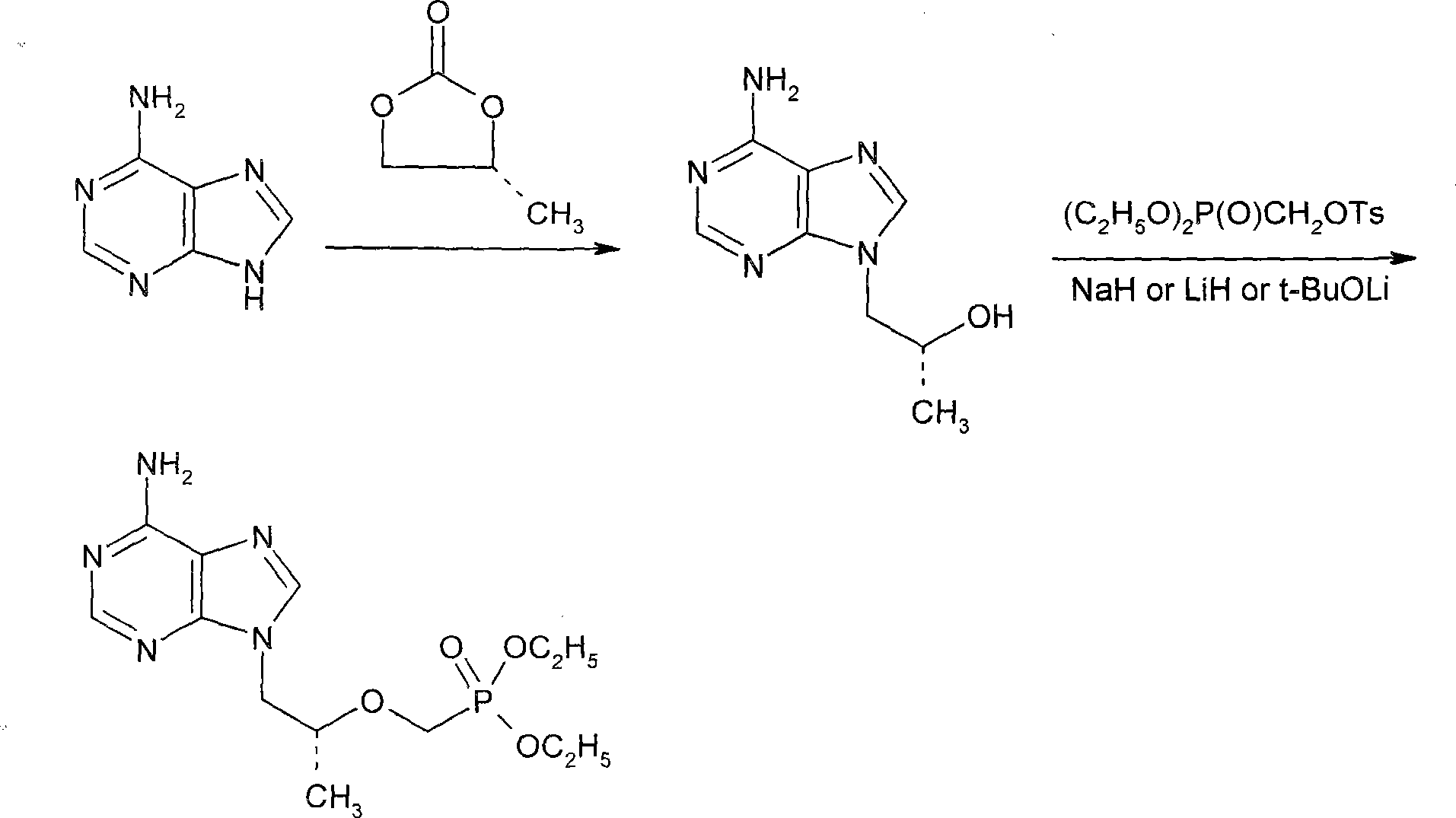

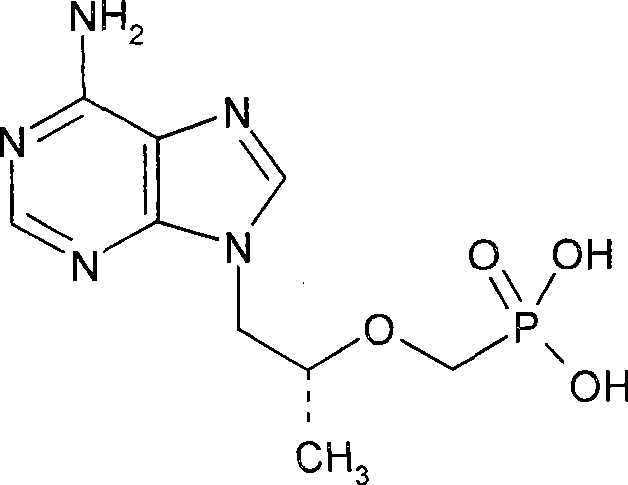

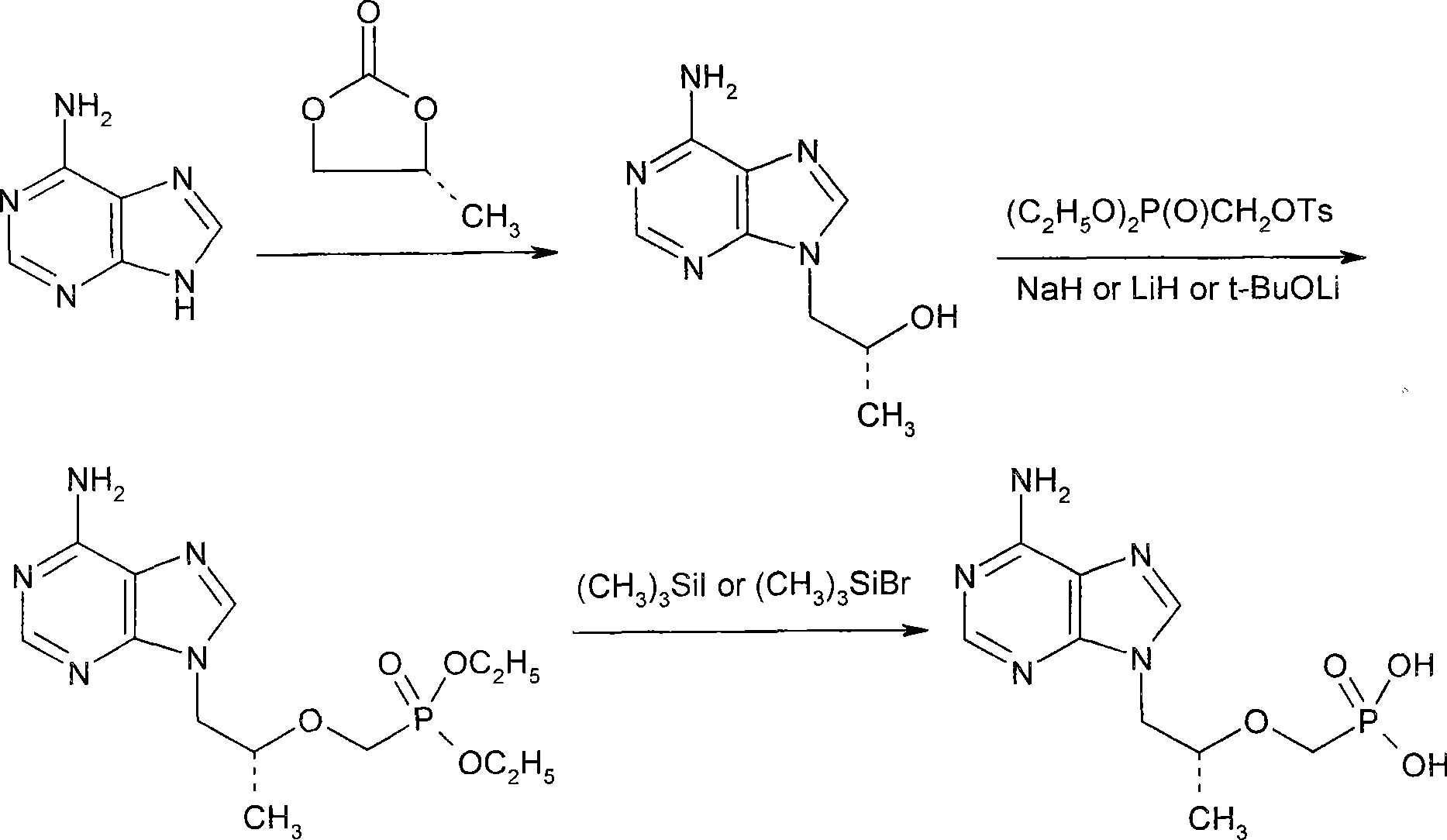

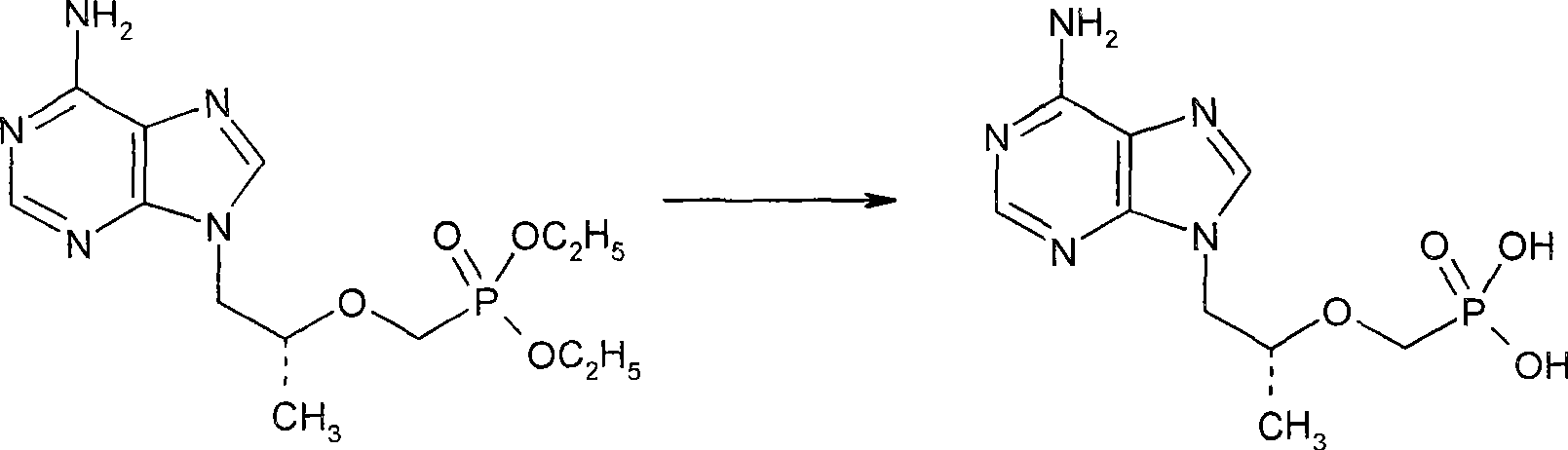

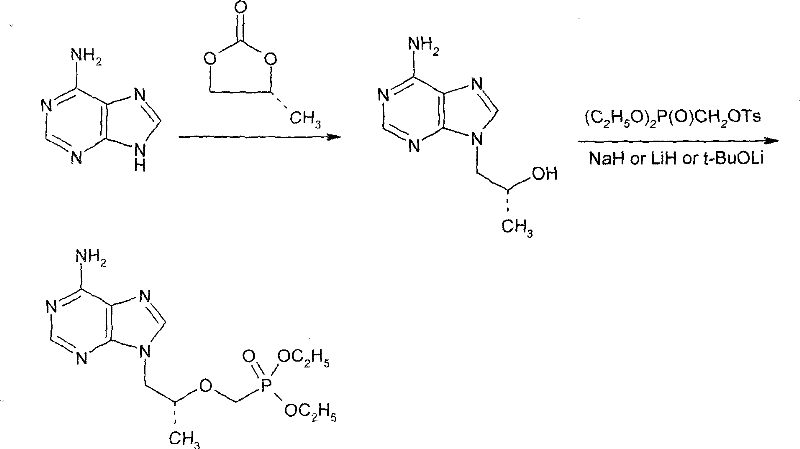

Method for synthesizing (R)-9(2-(diethyl phosphonyl methoxyl) propyl)-adenine

ActiveCN101531680AHigh yieldHigh purityGroup 5/15 element organic compoundsAntiviralsDiethyl phosphateSolvent

The invention provides a method for synthesizing (R)-9(2-(diethyl phosphonyl methoxyl) propyl)-adenine. The method includes the following steps of: implementing condensation reaction of (R)-hydroxypropyl adenine and tosyloxy methyl diethyl phosphate in solvent under the catalysis of catalytic amount of dialkyl magnesium, and then collecting generated PMPA diethyl ester from the reaction product. By using the method to produce the PMPA diethyl ester, the yield rate and the purity can be improved to over 80 percent, the used agent is safe, and the process operation is easy to control.

Owner:YANCHENG DESANO PHARMA CO LTD +1

Method for preparing artemether from artemether synthetic mother liquor

The invention discloses a method for preparing artemether from artemether synthetic mother liquor. The method includes: using organic solvent to dissolve solid obtained by concentrating and drying artemether synthetic mother liquor, sampling on a macroporous resin column, using acetone with the volume concentration of 20-70% for eluting, performing thin layer chromatographic detection, and fractionally collecting eluant containing alpha-artemether and eluant containing beta-artemether; and respectively recovering solvents in the eluant containing alpha-artemether and the eluant containing beta-artemether, filtering to obtain crude alpha-artemether and crude beta-artemether, using ethanol to dissolve the crude alpha-artemether and the crude beta-artemether, and adding water for crystallization to obtain alpha-artemether and beta-artemether. Compared with the prior art, the method has the advantages that the alpha-artemether and the beta-artemether are successively separated from the artemether synthetic mother liquor, filler for chromatography is cheap and simple in regeneration, and elution solvent is simple and easy to recovery; and the whole process is simple and easy to control, the production cost is low, and industrial production is easier to implement.

Owner:GUILIN PHARMA

Synthesis method of diphenylphosphine chloride

PendingCN110218226AHigh yieldHigh purityGroup 5/15 element organic compoundsChemical synthesisBenzene

The invention discloses a synthesis method of diphenylphosphine chloride, belongs to that technical field of chemical synthesis and solves the problem of low yield of the prior diphenylphosphoric chloride product. The synthesis method of diphenylphosphine chloride is characterized by comprising the following steps: under that protection of dry nitrogen, opening and stirring, adding benzene, phosphorus trichloride and catalyst to a reactor, and raising the temperature to 50 DEG C-80 DEG C and performing reflux reaction at 50 DEG C-80 DEG C for 2-3 h; after the reaction in step S01 is completed, raising the temperature to 85-200 DEG C and performing reflux reaction at 85-200 DEG C; at that end of step S02, after the reactor is cooled down, adding benzene into the reactor, adding a decomplexing agent, stirring until the decomplexing agent is dissolved and distilling to remove benzol, and then performing vacuum distillation to obtain the front fraction and the rear fraction. The inventionhas the advantages of high product yield.

Owner:ZHEJIANG YANGFAN NEW MATERIALS

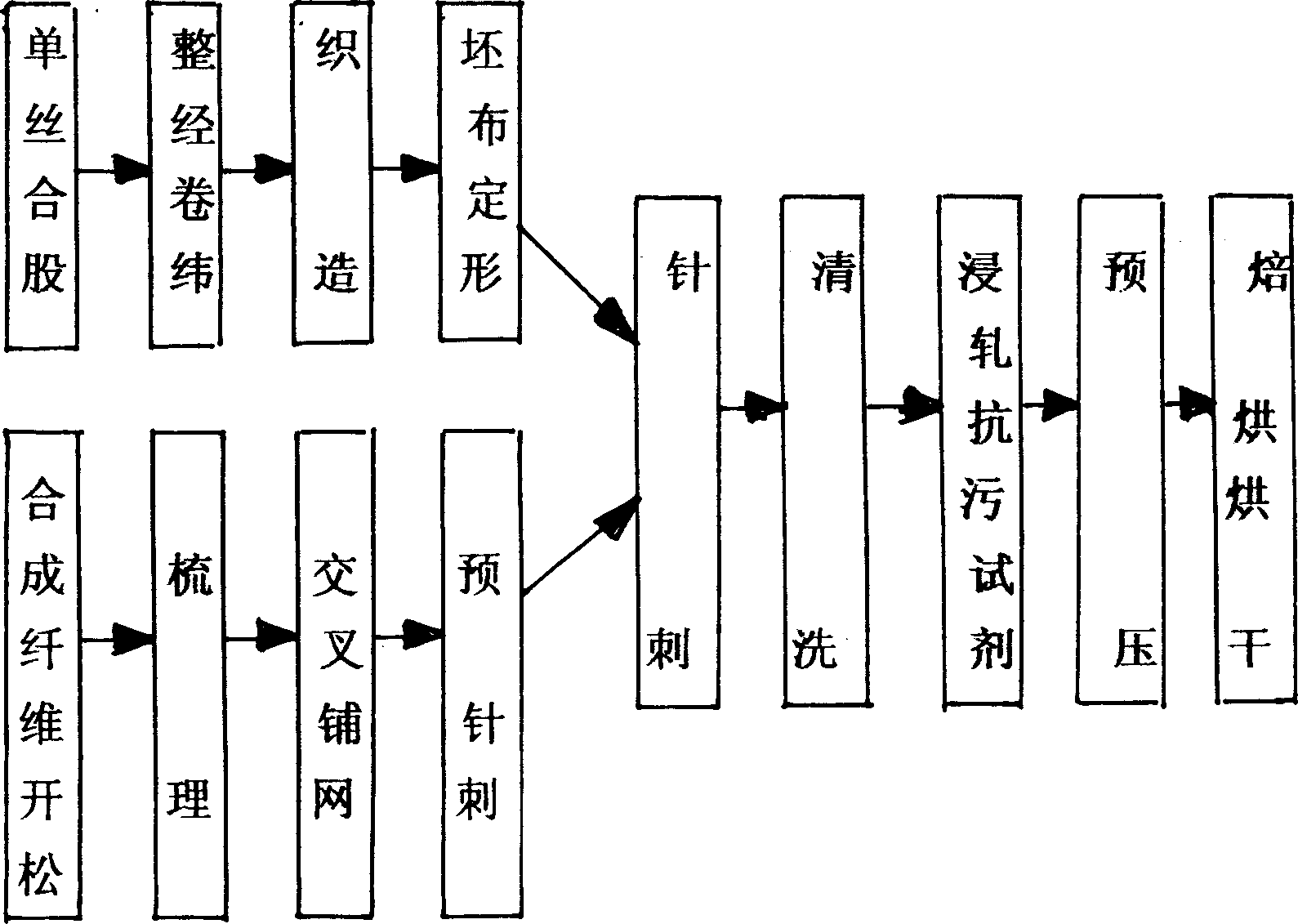

Method for manufacturing antifouling Batt-on-mesh press felt

The invention discloses a pollution-resisting web squeezing paper blanket making method, which is characterized by the following: forming paper-making blanket of weaved bottom web grey cloth through profiling and punching; impregnating the blanket through pollution-resisting agent within fluorine compounds and adhesive after cleaning; precompressing and baking the blanket to generate pollution-resisting web squeezing paper blanket, wherein the pollution-resisting agent formulation is the adhesive of polytef and melamine. The method contains obvious pollution-resisting effect, rational making method and easy operation, which reduces the disposal cost and improves the product added value greatly.

Owner:上海金熊造纸网毯有限公司

Compound and preparation method and application thereof

InactiveCN106928186AIncrease productivityStarting materials are cheap and readily availableOrganic chemistryBulk chemical productionReference productCombinatorial chemistry

The invention provides a compound shown in the formula 1 and a preparation method and application thereof. The method comprises the steps that 1, a compound shown in the formula 2 makes contact with trimethylsulfoxonium iodide to obtain a compound shown in the formula 3; 2, the compound shown in the formula 3 is subjected to a ring-opening reaction to obtain a compound shown in the formula 4; 3, an amino group of the compound shown in the formula 4 is subjected to a ring-closure reaction to obtain a compound shown in the formula 5; 4, the compound shown in the formula 5 is subjected to a de-tetrahydropyrane protection group reaction to obtain a compound shown in the formula 6; 5, the compound shown in the formula 6 is subjected to a molecular inner ring oxidation reaction to obtain a compound shown in the formula 7; 6, the compound shown in the formula 7 makes contact with a compound shown in the formula 8 to obtain the compound shown in the formula 1. According to the method, the compound shown in the formula 1 can be effectively prepared and effectively applied to quality control over an Efinaconazole drug by serving as a reference product.

Owner:WATERSTONE PHARMA WUHAN

Method and system for extracting rubidium salt and cesium salt from mother liquor after extracting lithium from lepidolite

InactiveCN106379922AHigh recovery rateHigh extraction control conditionsRubidium/caesium/francium compoundsSeparation coefficientRubidium

The invention provides a method for extracting rubidium salt and cesium salt from mother liquor after extracting lithium from lepidolite, which is characterized by comprising the following steps: 1) adjusting a high salinity solution into an alkaline solution; 2) extracting rubidium ions and caesium ions in the alkaline solution obtained in the step 1) by adopting an organic extractant, so as to obtain a loaded organic phase I and raffinate; 3) washing the organic phase I obtained in the step 2), so as to obtain an organic phase II and washing liquor; 4) carrying out back extraction on the loaded organic phase II with back extraction acid I, so as to obtain rubidium salt back extraction liquor and a cesium ion-loaded organic phase; and 5) carrying out back extraction on the cesium ion-loaded organic phase obtained in the step 4) with back extraction acid II, so as to obtain cesium salt back extraction liquor and a blank organic phase. According to the invention, the mother liquor after extracting lithium from lepidolite is controlled to be a strong alkali state, and the solution after back extraction has relatively low impurity content, so that the separation coefficient is high. According to the invention, the mother liquor after extracting lithium from lepidolite is controlled to be a strong alkali state, and the extraction becomes complete, so that the recovery rate is high.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

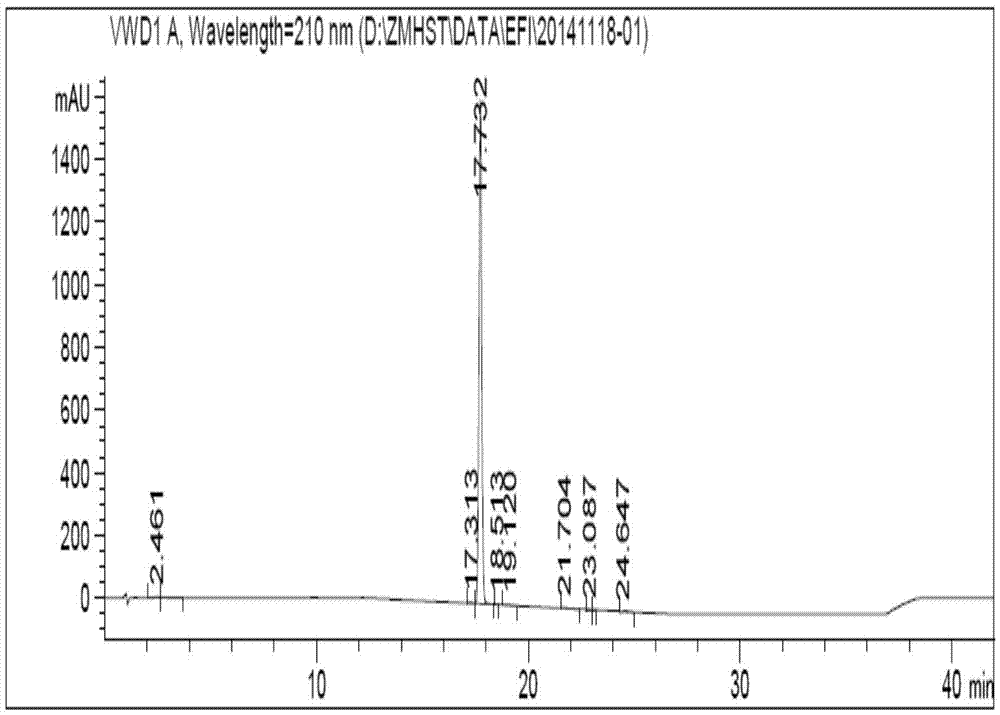

Compound and preparation method and application thereof

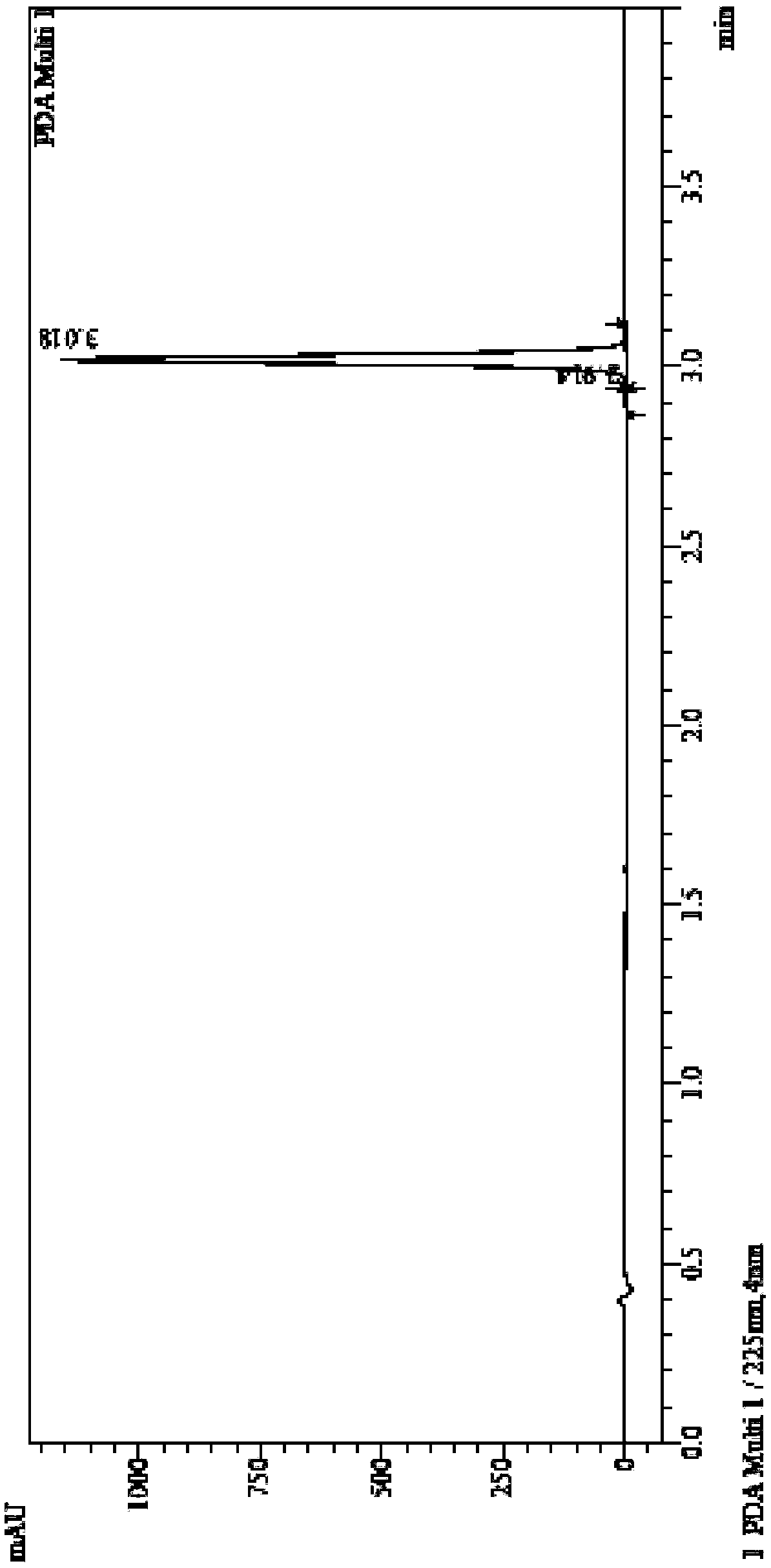

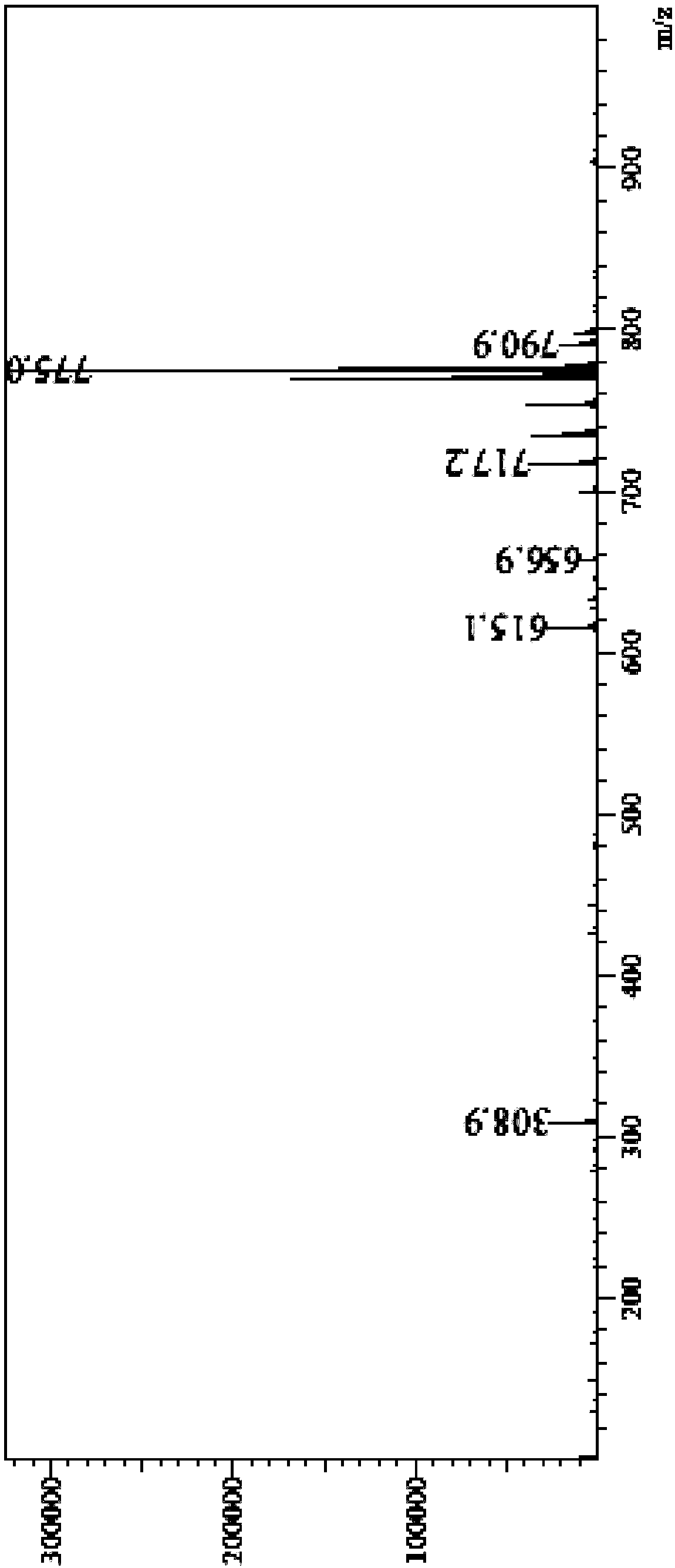

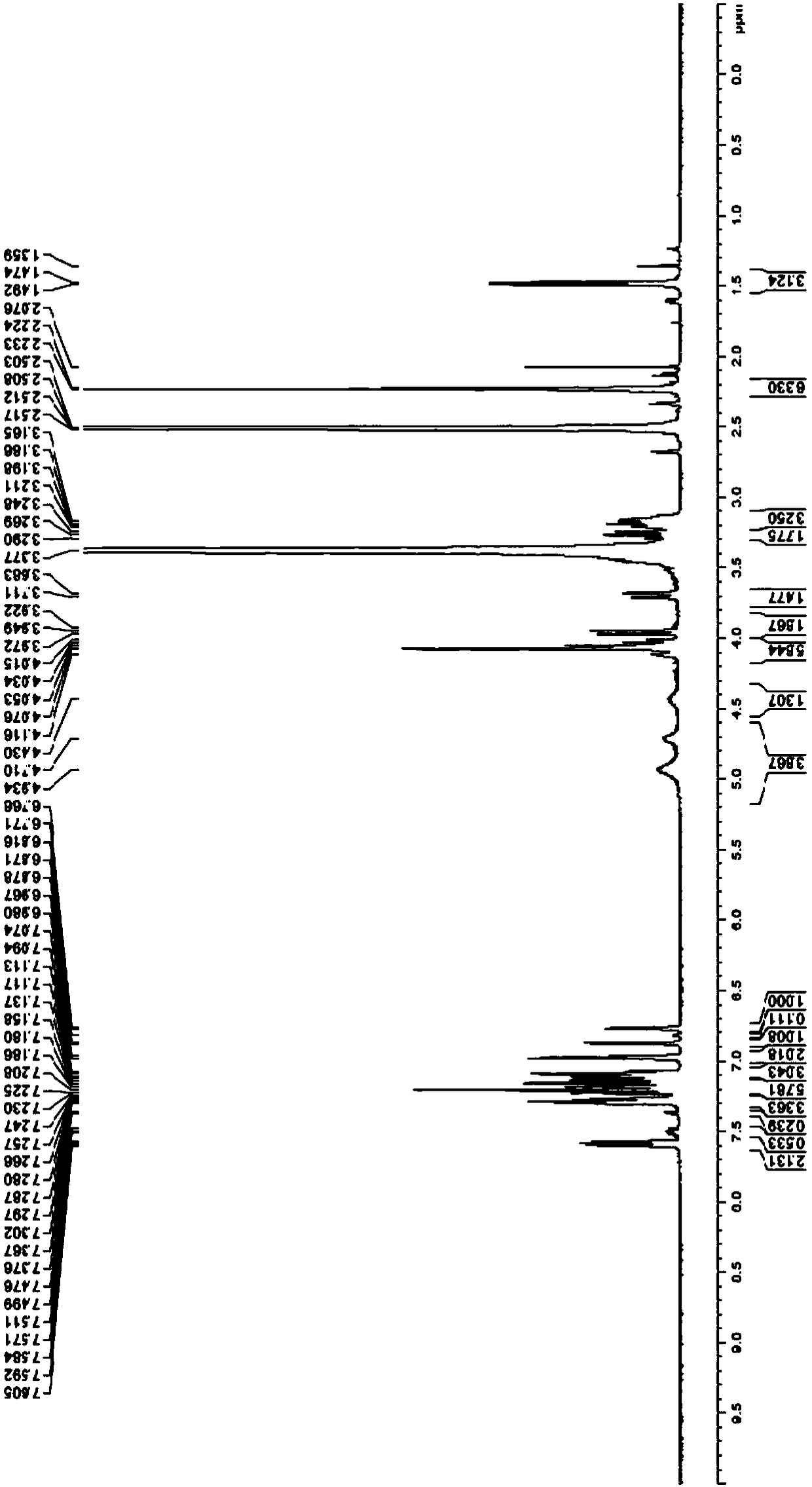

InactiveCN106279072AEfficient preparationThe reaction mechanism is clearOrganic chemistryImpurityHplc mass spectrometry

The invention provides a compound shown in the formula I and a preparation method thereof and a method for detecting Gliflozin medicine through high performance liquid chromatography. According to the preparation method, 3,5,6-tribenzyl-D-glucofuranose serves as a raw material, a methylation reaction, a benzyl substitution reaction, demethylating and ketalation are carried out, 3,5,6-tribenzyl-D-glucofuranose and a halide intermediate are subjected to a nucleophilic addition, the material makes contact with triethyl silicane and boron trifluoride diethyl etherate, finally, the material makes contact with ethanethiol and boron trifluoride diethyl etherate, and the target impurity product can be obtained. By means of the method, directional preparation is achieved for synthesis of the target product; the target product provides a reliable impurity reference substance for quality research and impurity quantitative control of industrially-produced Gliflozin series diabetes treatment medicine products. The formula I is shown in the specification.

Owner:WATERSTONE PHARMA WUHAN

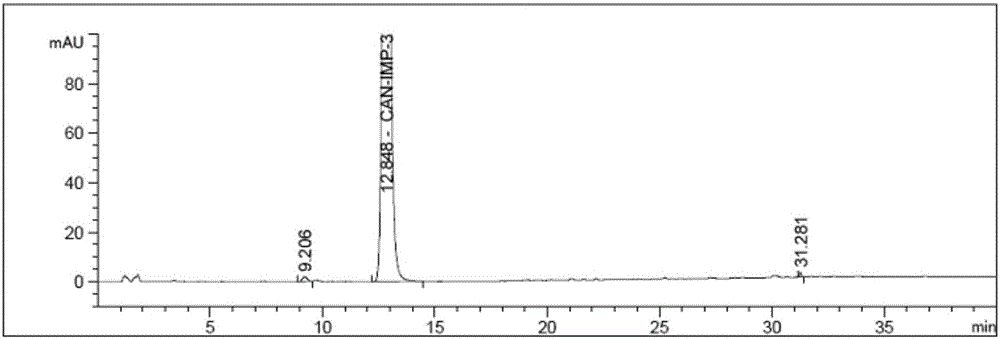

Canagliflozin drug impurity as well as preparation method and application thereof

ActiveCN107286143AStarting materials are cheap and readily availableReduce stepsOrganic chemistry methodsOrganic solventLithium hydroxide

The invention discloses a canagliflozin drug impurity as well as a preparation method and application thereof. The invention provides a compound as well as a preparation method and application thereof. The method comprises the following steps: (1) enabling the compound as shown in formula 2 to be in contact with an alkaline lithium hydroxide aqueous solution to obtain a coarse product containing a compound as shown in formula 3, wherein the coarse product contains a compound as shown in formula 1; (2) crystallizing and filtering the coarse product to obtain mother liquor; (3) concentrating the mother liquor to obtain residues; and (4) crystallizing and filtering the residues in an L-proline-containing organic solvent, thus obtaining the compound as shown in formula 1. The method provided by the invention can realize directed preparation of the compound as shown in formula 1, and a reliable impurity contrast is provided for quality research on industrially produced canagliflozin-series diabetes treatment drug products and quantitative control over impurities.

Owner:WATERSTONE PHARMA WUHAN

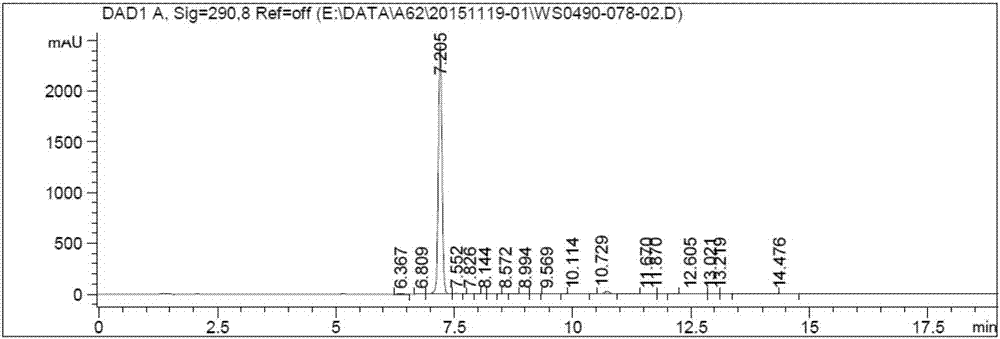

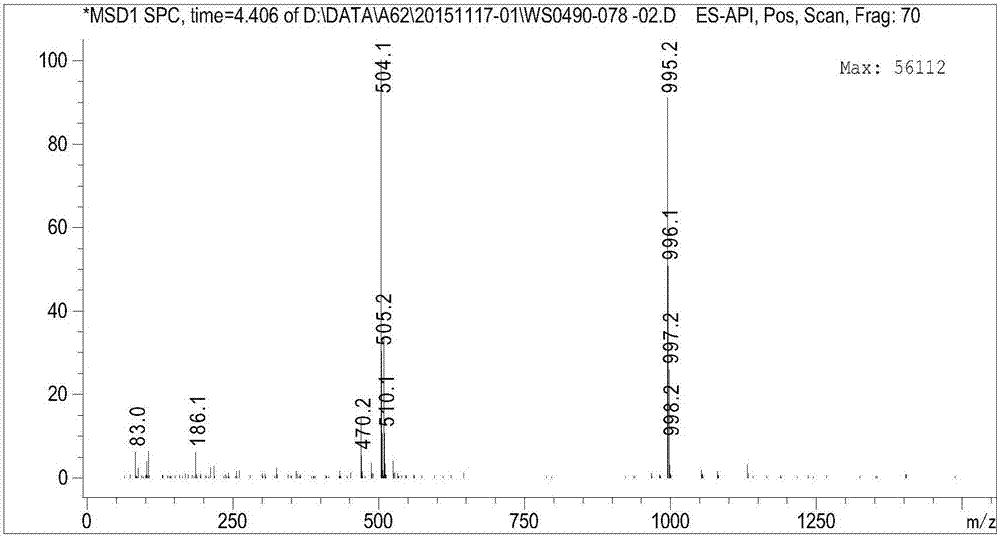

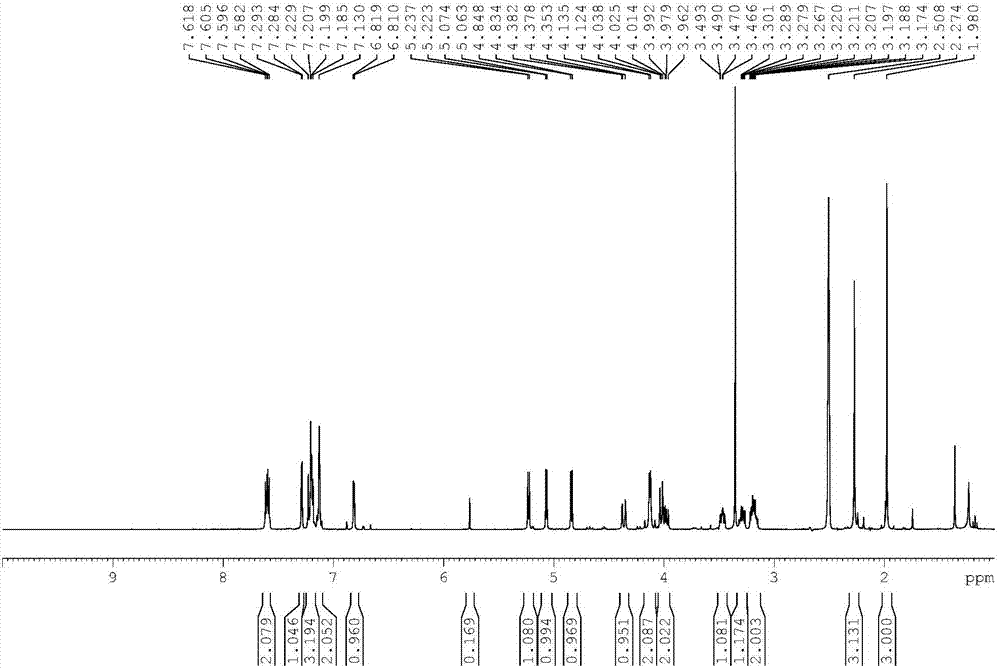

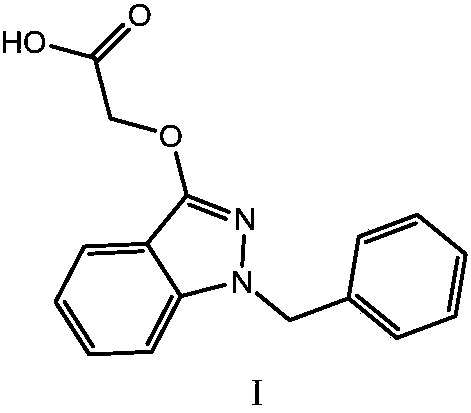

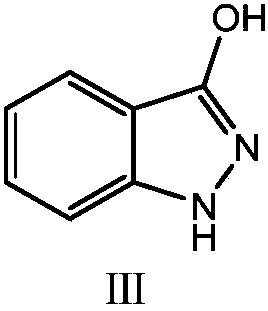

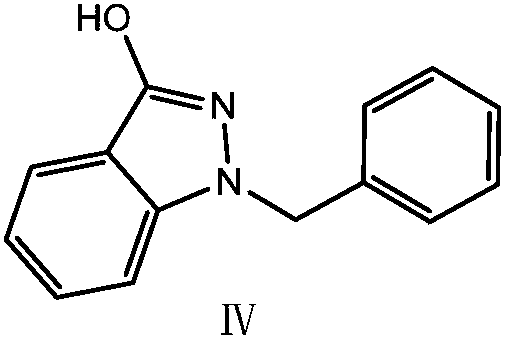

Preparation method for bendazac

InactiveCN107641103ACheap sourceProcess operation is easy to controlOrganic chemistryBenzoic acidPotassium hydroxide

The invention provides a preparation method for bendazac. The preparation method comprises the following steps: adding o-halogen benzoic acid, inorganic alkali, a catalyst, a hydrazine compound and asolvent into a reactor, carrying out stirring at 75 to 110 DEG C for 20 to 48 h, carrying out spin-drying, carrying out extraction with an alcohol extractant, and carrying out washing so as to obtainan intermediate III; successively adding the intermediate III, benzyl chloride, sodium hydroxide and water into the reactor, maintaining the temperature in a range of 20 to 75 DEG C, and carrying outcooling, vacuum filtering and washing so as to obtain an intermediate IV; and successively adding the intermediate IV, potassium hydroxide and glycol dimethyl ether into the reactor, carrying out dissolving and clarification under heating, then dropwise adding a glycol dimethyl ether solution of chloroacetic acid, maintaining the temperature in a range of 60 to 85 DEG C, carrying out stirring for4 h, carrying out spin-drying, adjusting acid until a white solid is extracted, carrying out acid-base purification, and carrying out centrifuging so as to obtain white solid bendazac. The method provided by the invention has the advantages of cheap raw material source, easily controllable process operation, high yield, stable quality, significantly-lowered cost compared with the cost of a conventional method, applicability to industrial production, etc.

Owner:合肥远志医药科技开发有限公司

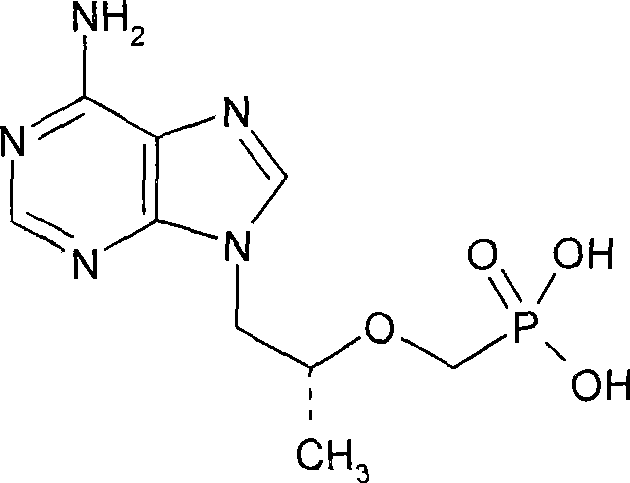

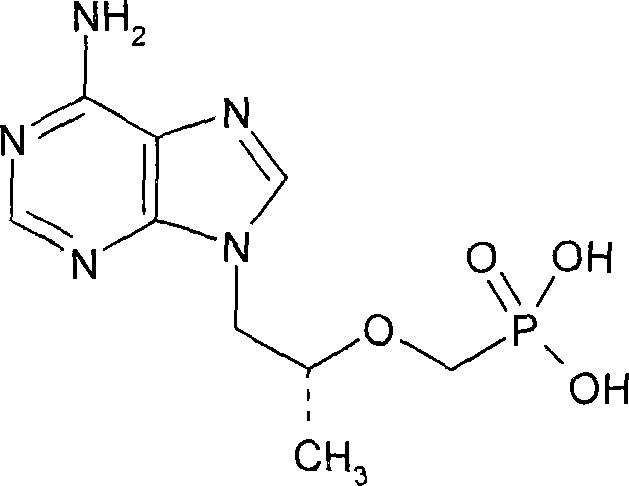

Method for preparing phosphonyl methoxyl nucleotide analogue

ActiveCN101531679ALow costProcess operation is easy to controlGroup 5/15 element organic compoundsAntiviralsTrimethylsilyl chlorideSolvent

The invention provides a method for preparing phosphonyl methoxyl nucleotide analogue, including the following steps of: implementing reflux reaction of (R)-9-(2-(diethyl phosphonyl methoxyl) propyl)-adenine and trimethylchlorosilane in solvent in the presence of catalytic amount of catalyst, and then collecting the target product: (R)-9-(2-(diethyl phosphonyl methoxyl) propyl)-adenine from the reaction product, wherein the catalyst is sodium halide. In the method, the used agent is cheap, easily available, safe and low in cost; the process operation is easy to control and the purity of product can reach over 99 percent.

Owner:江西迪赛诺制药有限公司

Technological method for extracting indium from zinc oxide generated from waste residue from zinc by hydro-smelting

ActiveCN101597692BInhibition of dissolutionReduce emulsificationProcess efficiency improvementIndiumZinc

The invention relates to the technical field of smelting indium, in particular to relates to a technological method for extracting indium from zinc oxide generated from waste residue from zinc by hydro-smelting. In the process of acidization, the zinc oxide of the invention is acidated by sulphuric acid; after the acid leaching of the zinc oxide, oxyful is used for the deep removal of iron by oxidation in the process of impurity removal of liquid; after the acidization of the zinc oxide, sulphuric acid is used for acidization leaching in a secondary leaching process; the multistage centrifugal extraction which is rich in indium liquid after impurity removal adopts the mixture of Cyanex923 and P204 as a composite extractant; and the back extraction adopts the mixed liquid of 3 mol / L HCL and 2 mol / L ZnC <2> as a back-extractant. The technological method for extracting the indium from the zinc oxide generated from the waste residue from zinc by hydro-smelting has the advantages that the indium smelting production technology parameter and equipment adapt to high altitude and low air pressure environment, the technology is simple, and the operability is high; and the application of themethod and the composite extractant of the invention can increase the recovery rate of indium by 10 to 15 percent.

Owner:青海西部铟业有限责任公司

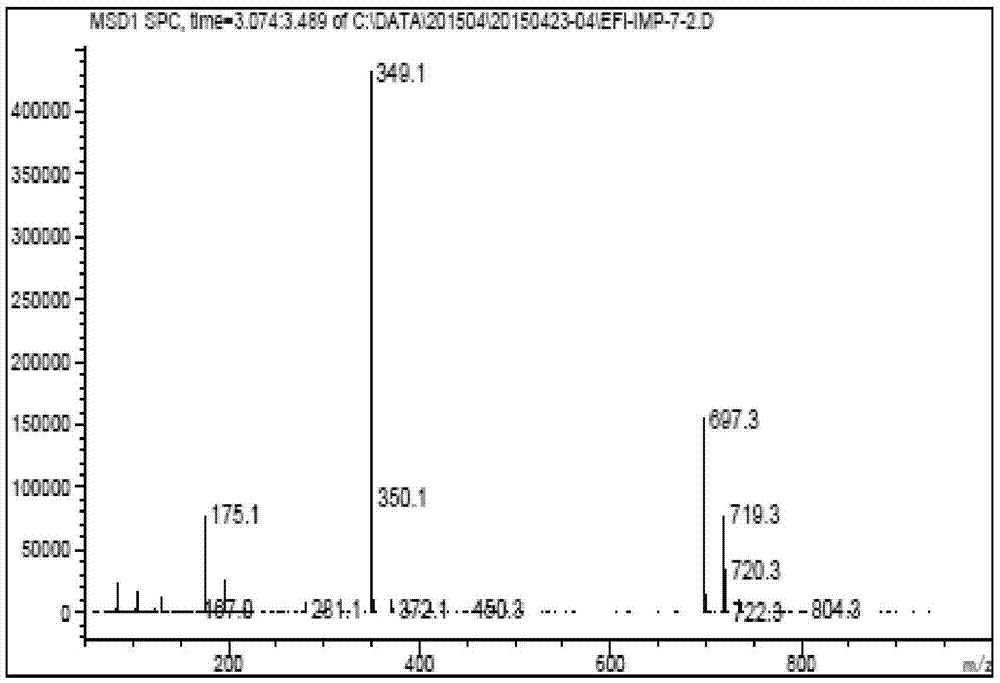

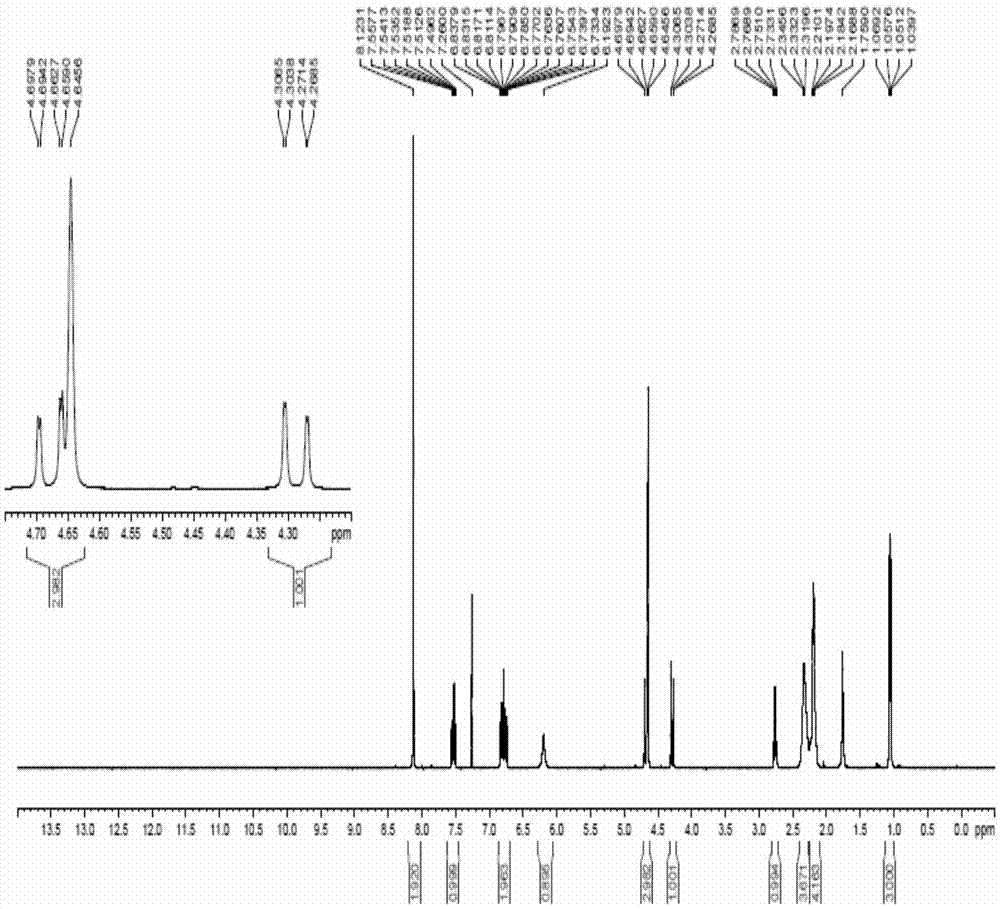

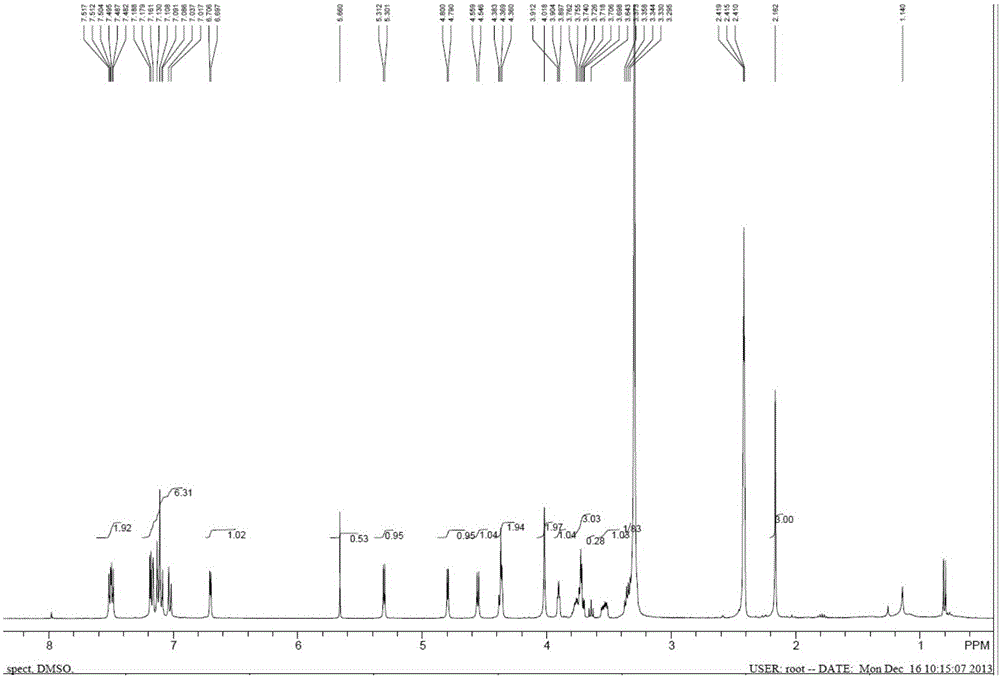

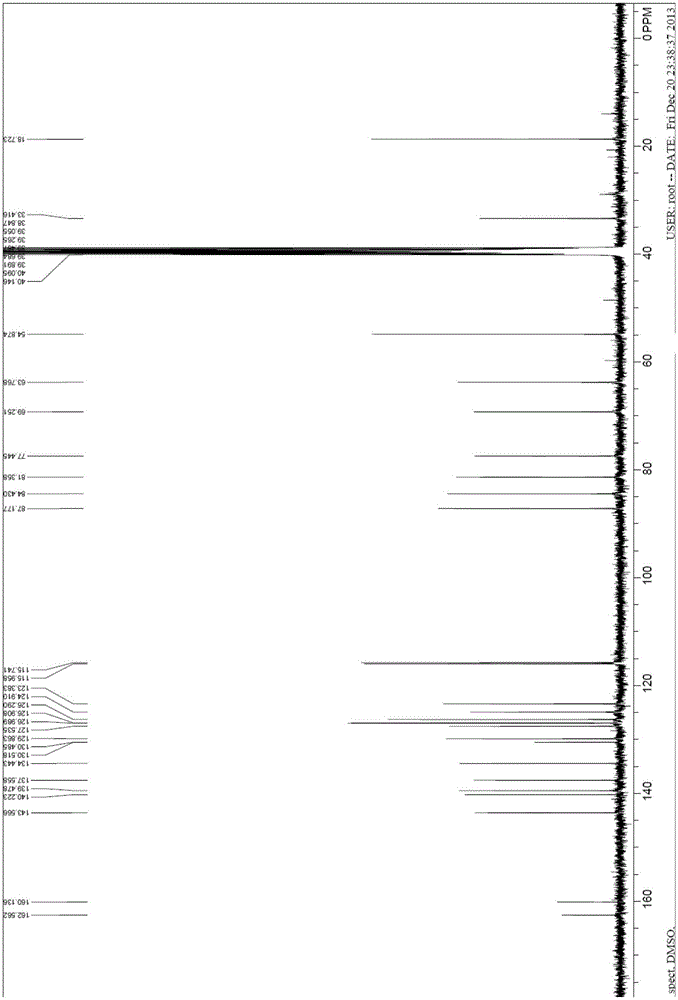

Compound as well as preparation method and application thereof

InactiveCN108586442AStarting materials are cheap and readily availableProcess operation is easy to controlOrganic chemistryComponent separationChemical synthesisQuality control

The invention relates to the field of chemical synthesis, in particular to a compound as well as a preparation method and application thereof. The compound is an impurity generated in the production process of canagliflozin, and can be applied to quality control of canagliflozin products by serving as a standard substance or a reference substance.

Owner:湖北华世通生物医药科技有限公司

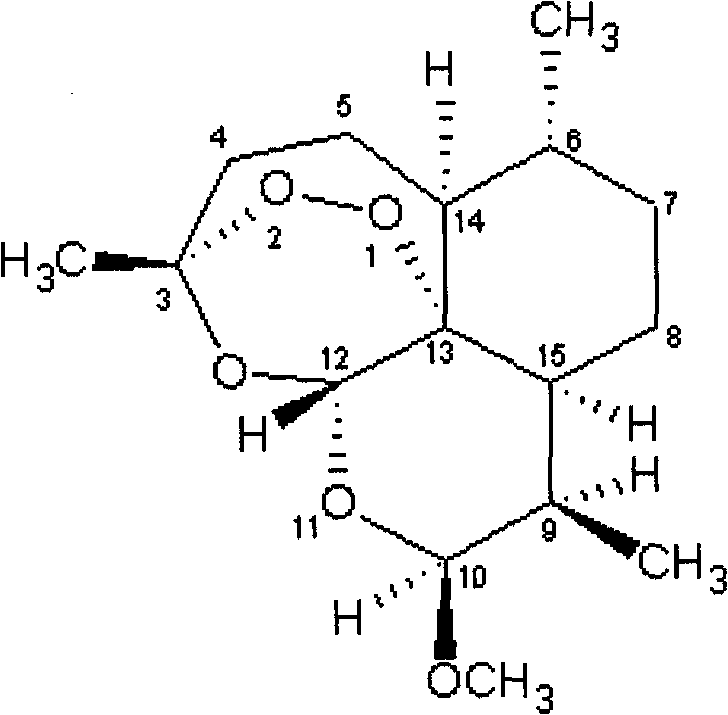

Process for preparing β-artemether

ActiveCN103180325BMeet the requirementsHigh yieldOrganic chemistryAntiparasitic agentsOrganic solventDihydroartemisinin

Provided is a method for synthesizing beta-Artemether. The method uses dihydroartemisinin as a raw material, which has an etherifying reaction with trimethyl orthoformate in an organic solvent in the presence of catalyst, to give beta-Artemether, with a byproduct alpha-Artemether content of less than 6%.

Owner:SHANGHAI DESANO PHARMA INVESTMENT +2

Method for preparing Y2Si2O7 whisker-toughened mullite composite coating

ActiveCN102924108BImprove the effect of anti-erosion shear stressImprove antioxidant capacityLoss rateActive agent

The invention relates to a method for preparing a Y2Si2O7 whisker-toughened mullite composite coating. The method comprises the following steps: preparing a SiC porous internal coating on the matrix surface of a C / C composite material through an embedding method, preparing Y2Si2O7 whiskers, and then performing surface modification to the Y2Si2O7 whiskers with a composite surface active agent to obtain a mixed liquor; and performing ultrasonic electrophoretic selective assembly deposition to the C / C composite material prepared with the SiC porous internal coating and the mixed liquor to obtain a Y2Si2O7 whisker pinning layer, and finally preparing the Y2Si2O7 whisker-toughened mullite composite coating through a hydrothermal electrophoretic deposition method. Compared with other coatings, the prepared Y2Si2O7 whisker-toughened mullite composite coating can effectively increase the oxidation-resistance temperature, can realize the anti-oxidation protection of 400 hours for the C / C composite material under the condition of dynamic brush of high temperature (1700 DEG C) gas, and the oxidation loss rate is lower than 0.77 percent.

Owner:杨洁如

Method for synthesizing (R)-9(2-(diethyl phosphonyl methoxyl) propyl)-adenine

ActiveCN101531680BHigh yieldHigh purityGroup 5/15 element organic compoundsAntiviralsDiethyl phosphateSolvent

The invention provides a method for synthesizing (R)-9(2-(diethyl phosphonyl methoxyl) propyl)-adenine. The method includes the following steps of: implementing condensation reaction of (R)-hydroxypropyl adenine and tosyloxy methyl diethyl phosphate in solvent under the catalysis of catalytic amount of dialkyl magnesium, and then collecting generated PMPA diethyl ester from the reaction product. By using the method to produce the PMPA diethyl ester, the yield rate and the purity can be improved to over 80 percent, the used agent is safe, and the process operation is easy to control.

Owner:YANCHENG DESANO PHARMA CO LTD +1

Method for preparing (R)-9-(2-phosphorylmethoxypropyl)adenyl-di(isopropoxycarbonylmethyl)ester

ActiveCN102453055BSources are cheap and readily availableProcess operation is easy to controlGroup 5/15 element organic compoundsSynthesis methodsAcetonitrile

The invention discloses a novel synthesis method of (R)-9-(2-phosphorylmethoxypropyl)adenyl-di(isopropoxycarbonylmethyl)ester, which comprises the following steps; after tenofovir used as a raw material and triethylamine are salified in acetonitrile, evaporating to remove acetonitrile, remaining triethylamine and water in the tenofovir triethylamine salt, and carrying out condensation reaction with chloromethylisopropyl carbonate to obtain the (R)-9-(2-phosphorylmethoxypropyl)adenyl-di(isopropoxycarbonylmethyl)ester. The method disclosed by the invention has the advantages of cheap and accessible raw material, easily controlled technological operation, high yield and low cost, and is suitable for industrial production.

Owner:YANCHENG DESANO PHARMA CO LTD +1

Wear-resistant liquid metal polymer self-lubricating composite material

ActiveCN112778695AIncrease frictionAvoid thermal failureOther chemical processesPoly ether ether ketoneLiquid metal

The invention discloses a wear-resistant liquid metal polymer self-lubricating composite material. The composite material comprises polyether-ether-ketone and liquid metal. In the friction process, the liquid metal absorbs friction heat and is changed into liquid through phase change, and a transfer film is formed between a polymer matrix and a friction pair. In the friction process of the material, friction heat can be taken away in time due to phase change heat absorption, and a stable liquid metal transfer film can be formed when the internal liquid metal lubricating grease is extruded by a load and is exposed out of a contact surface, so that direct contact of a friction surface is blocked, the friction coefficient of the composite material is effectively reduced, and the wear resistance of the material is improved. The material can be applied to sealing elements under high-temperature, high-pressure and high-speed working conditions.

Owner:NANJING UNIV OF TECH

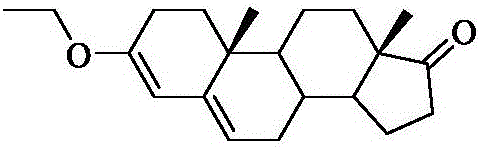

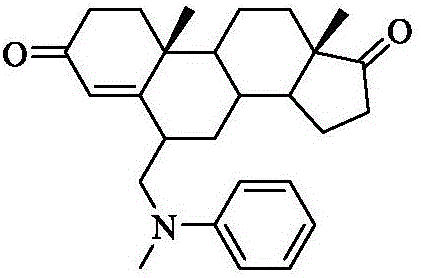

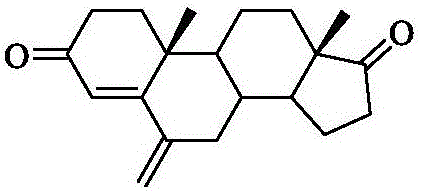

Industrial production method of exemestane

An industrial production method of exemestane comprises the following steps: adding androsta-1,4-diene-3,17-dione, anhydrous ethanol, triethyl orthoformate and p-toluenesulfonic acid into a reactor, stirring above added materials, carrying out rotary drying, and crystallizing the obtained dried mixture to obtain an intermediate YXMT01; sequentially adding the intermediate YXMT01, anhydrous ethanol, tetrahydrofuran, 37% formaldehyde, N-toluidine and p-toluenesulfonic acid into the reactor, and carrying out rotary drying to obtain an intermediate YXMT02; sequentially adding the intermediate YXMT02, ethyl acetate and hydrochloric acid into the reactor, precipitating, carrying out suction filtration to obtain white solid, and re-crystallizing the white solid with toluene to obtain an intermediate YXMT03; and sequentially adding the intermediate YXMT03, toluene and IBX into the reactor, stirring the added substances, cooling the obtained substance, concentrating the obtained filtrate, and re-crystallizing the obtained concentrate to obtain white solid YXMT. The method has the advantages of avoiding of uncontrollability of a one-kettle method in industrial production, cheap sources of raw materials, easiness in control of the process operation, high yield, stable quality, and suitableness for industrial production.

Owner:NANJING CHENGONG PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com