Wear-resistant liquid metal polymer self-lubricating composite material

A liquid metal, composite material technology, applied in other chemical processes, chemical instruments and methods, etc., to achieve the effect of simple and controllable process operation, reducing the risk of leakage, and avoiding thermal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

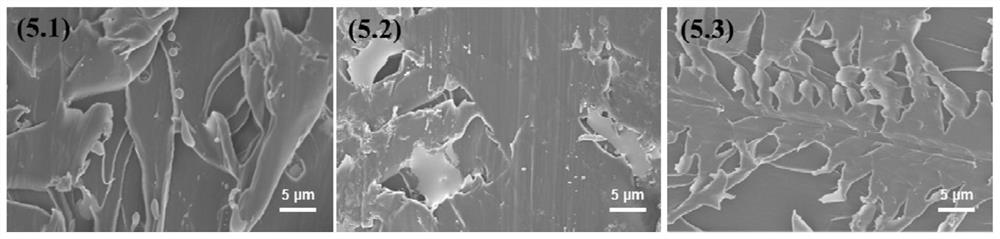

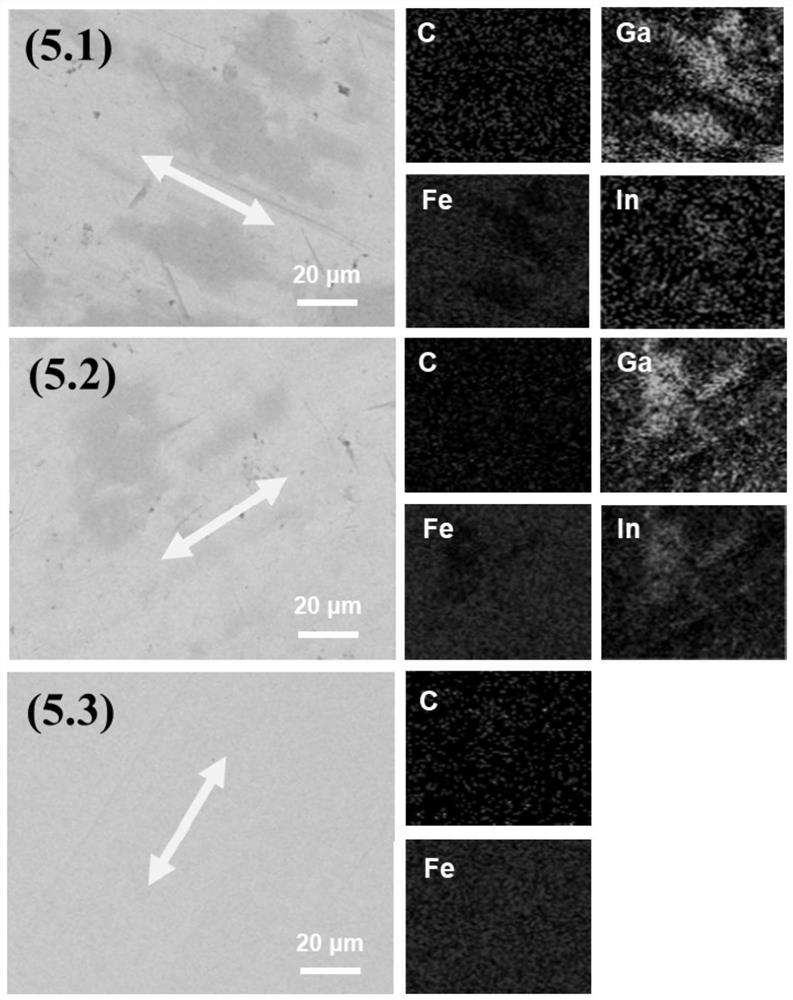

[0043] First put 1g of Bi 44.7 Cd 5.3 In 19.1 Pb 22.6 sn 8.3 Add it to 5g of 50mmol / L gamma-(2,3-glycidoxy)propyltrimethoxysilane methanol solution, put it in a hot water bath at 60°C, ultrasonic frequency is 50KHz, and ultrasonicate for 2h at 80% ultrasonic power to obtain Liquid metal microspheres with an average diameter of 0.2 μm. Then 18g of polyether ether ketone, 5g of carbon fiber and the previous liquid metal particles were wet mixed and stirred, and the mixture was dried at 105° C. for 3 hours to obtain a dry mixture powder. The powder was placed in a stainless steel mold, kept at 300°C for 40 minutes, then hot-pressed at 50 MPa for 1 hour at this temperature, and then cold-pressed at 280°C for 20 minutes to obtain a wear-resistant liquid metal polymer self-lubricating composite material. The friction and wear performance is tested by MPX-2000 friction and wear testing machine, the load is 200N, the speed is 1.4m / s, and the test time is 2h.

Embodiment 21

[0053] First, 0.3g of Bi 32.5 In 51 sn 16.5 Add to 0.3g 80mmol / L dodecanethiol acetone solution, heat bath at 70°C, ultrasonic frequency 40KHz, ultrasonication at 75% ultrasonic power for 1.5h, to obtain liquid metal microspheres with an average diameter of 1.5μm. Then 17.7g of polyether ether ketone, 2g of glass fiber and the previous liquid metal particles were wet mixed and stirred, and then the mixture was dried at 102°C for 2 hours to obtain a dry mixture powder. The powder was placed in a stainless steel mold, kept at 320°C for 50 minutes, then hot-pressed at 72MPa for 2 hours at this temperature, and then cold-pressed at 280°C for 15 minutes to obtain a wear-resistant liquid metal polymer self-lubricating composite material. The test method is the same as in Example 1.1.

Embodiment 31

[0063] First, 0.48g of Bi 33 In 67 Add to 3.2g 65mmol / L octadecanethiol ethanol solution, heat bath at 80°C, ultrasonic frequency 48KHz, ultrasonication at 65% ultrasonic power for 0.5h, to obtain liquid metal microspheres with an average diameter of 2.1μm. Then 25.12g of polyether ether ketone, 6.4g of aramid fibers and the previous liquid metal particles were wet mixed and stirred, and the mixture was dried at 108°C for 3 hours to obtain a dry mixture powder. Put the powder in a stainless steel mold, keep it at 350°C for 46min, then hot press at 54MPa for 1.5h at this temperature, then lower it to 270°C and then cold press for 28min to obtain liquid metal reinforced polyetheretherketone wear-resistant self-lubricating composite material. The test method is the same as in Example 1.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com