Technological method for extracting indium from zinc oxide generated from waste residue from zinc by hydro-smelting

A technology of wet smelting and process method, applied in the field of extracting indium, can solve the problems of large loss of extractant, high concentration of back-extractant, weak regeneration ability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

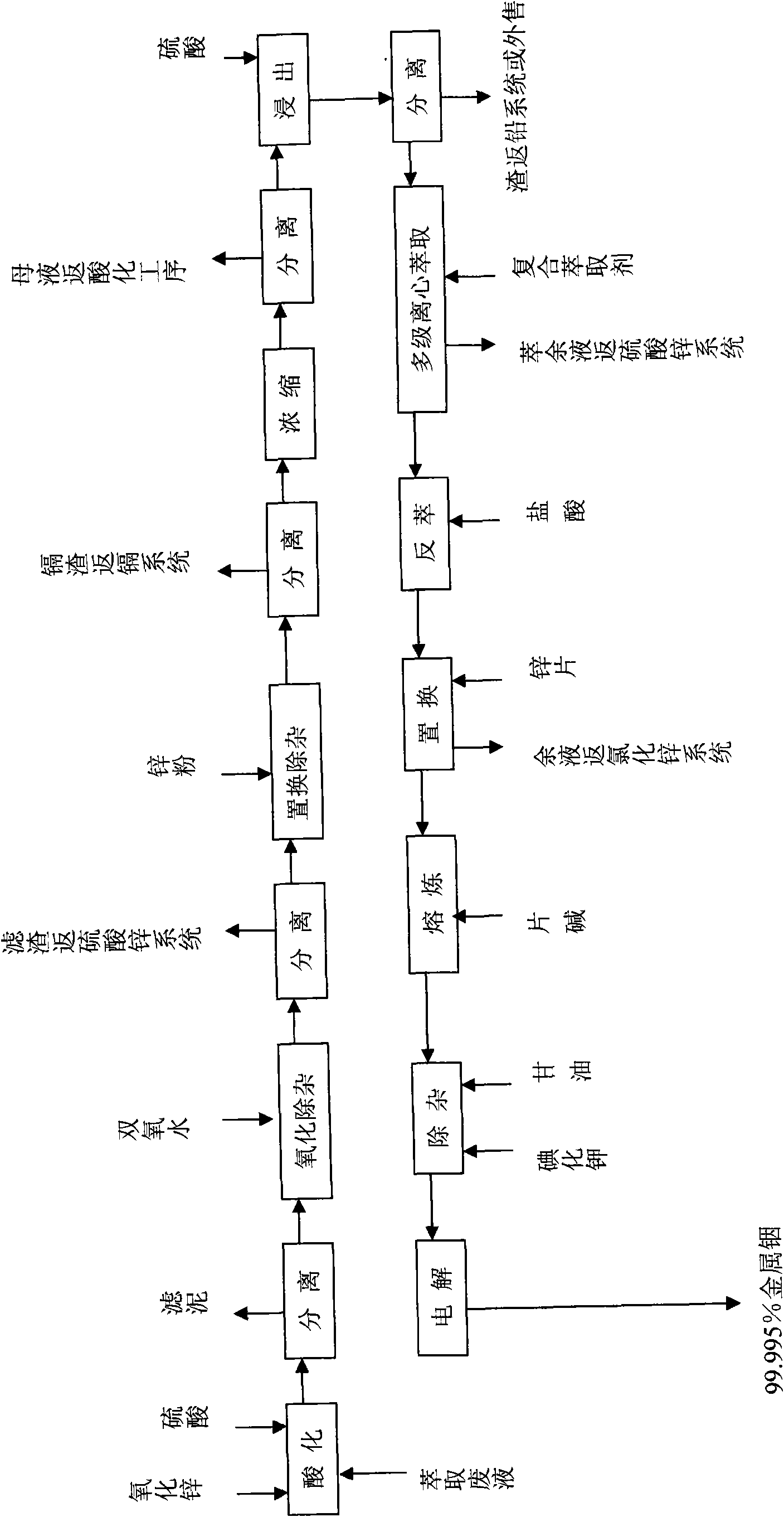

Method used

Image

Examples

Embodiment 1

[0027] The main chemical composition of the indium extraction material (zinc oxide produced from zinc hydrometallurgy waste slag): Zn: ≥ 35%; In: ~0.05%.

[0028] Zinc oxide acid leaching process

[0029] Sulfuric acid is used in the acid leaching process, and the main reactions are as follows:

[0030] ZnO+H 2 SO 4 =ZnSO 4 +H 2 o

[0031] In 2 o 3 +3H 2 SO 4 = In 2 (SO 4 ) 3 +3H 2 o

[0032] PbO+H 2 SO 4 =PbSO 4 +H 2 o

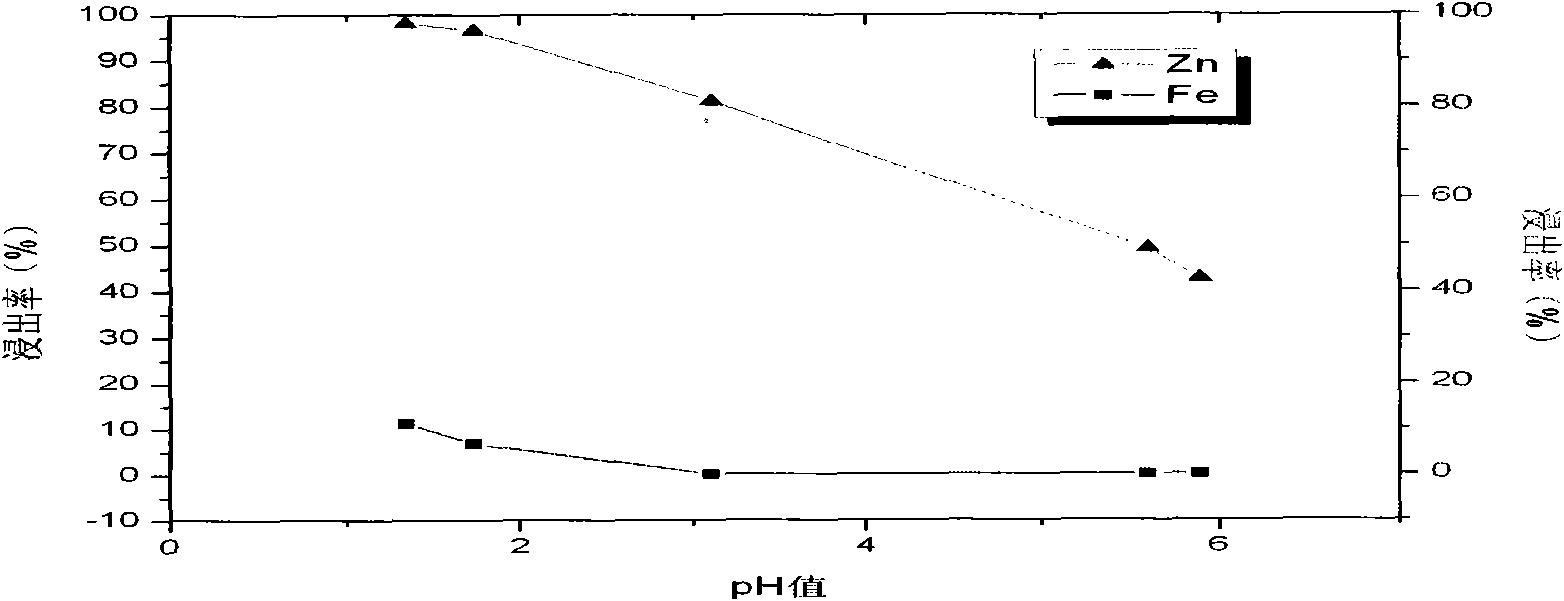

[0033] At the same time, impurities such as Cu and Fe in the zinc oxide material also partially react with sulfuric acid to form soluble sulfate and enter the solution. Since iron is a trivalent ion, it has a great impact on indium during extraction, while other ions are not extracted. .

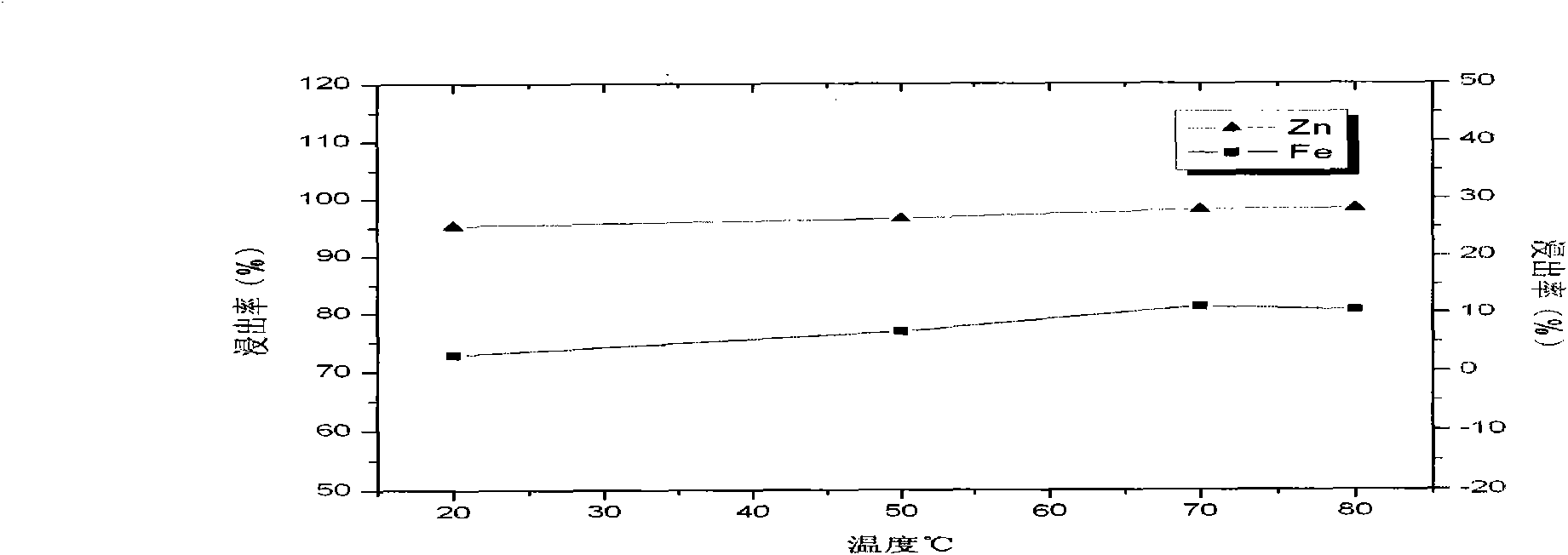

[0034] Acidity, temperature, pickling time, etc. have a great influence on the leaching rate. With the increase of acidity, the leaching rate of various components increases.

[0035] by right figure 2, 3 , 4, and combined with the characteristics of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com