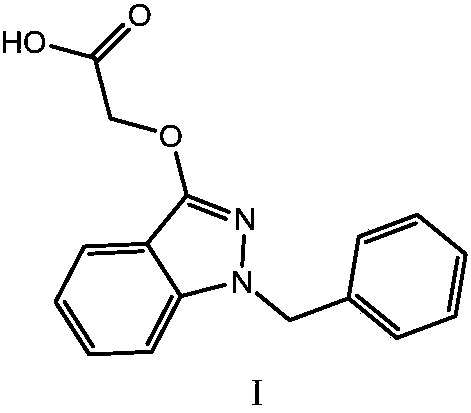

Preparation method for bendazac

A technology of benzylic acid and benzoic acid, applied in the field of benzylic acid preparation, can solve the problems of complex process operation, difficult control, low yield and the like, and achieve the effects of high yield, reduced cost and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

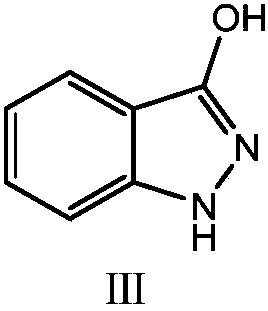

[0020] 1. The preparation of intermediate III, the chemical formula of intermediate III is as follows:

[0021]

[0022] Add 10Kg of o-chlorobenzoic acid, 85g of cuprous oxide, 12Kg of anhydrous sodium carbonate, 21Kg of hydrazine hydrate, and 80Kg of toluene into the reactor, heat up to 85°C and stir for 36 hours. After the reaction is complete, add 24Kg of ethanol when the temperature is lowered to 20°C and stir Centrifuge for 0.5h, evaporate the mother liquor to dryness, evaporate the solid and wash it with beating water, and dry at 50°C for 12h to obtain 6.5Kg of white solid intermediate III with a yield of 75.8%. The o-chlorobenzoic acid can be replaced by o-bromobenzoic acid, Any one of o-iodobenzoic acid, the anhydrous sodium carbonate can be replaced by any one of anhydrous potassium carbonate and sodium hydroxide, the equivalent is 1 to 1.5 equivalents of the raw material, and the hydrazine hydrate can be replaced by hydrochloric acid Hydrazine, the equivalent is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com