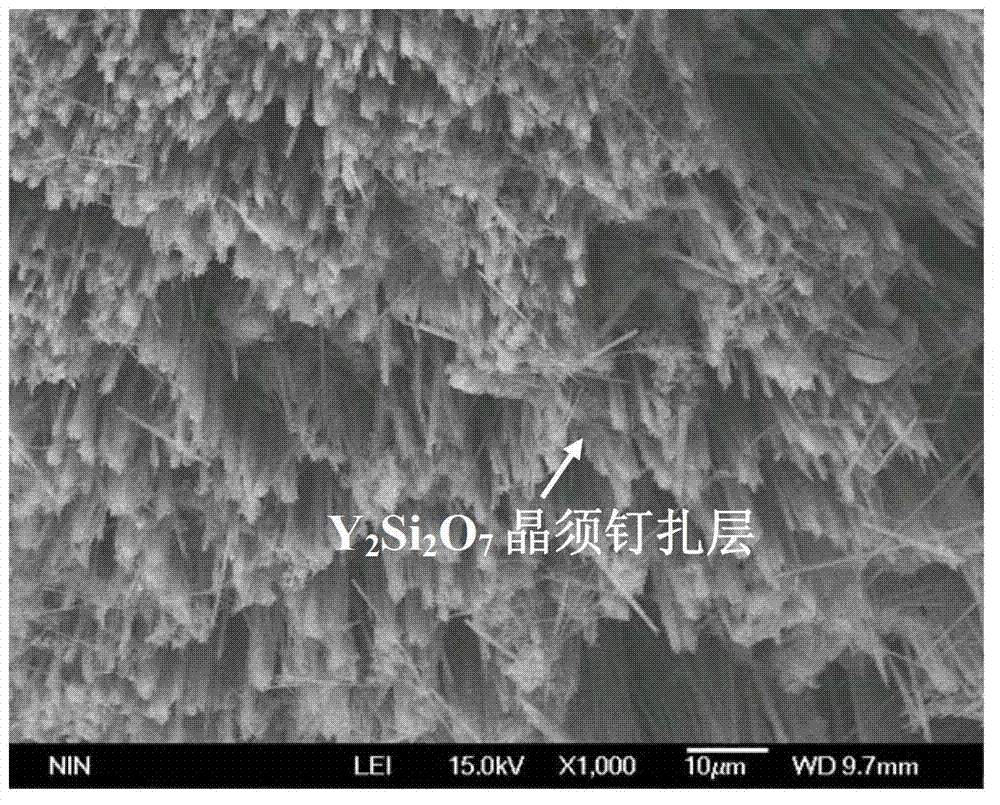

Method for preparing Y2Si2O7 whisker-toughened mullite composite coating

A composite coating and mullite technology, applied in the field of C/C composite materials, can solve the problems of unreachable, easy to fall off, oxidation protection time, etc., and achieve the effects of small oxidation weight loss rate, good interface bonding and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: C / C composite material pretreatment package:

[0034] 1) Take the 2D-carbon / carbon composite material used for aircraft brake pads and process it into 30×30×30mm 3 Cube, and polished and chamfered the surface, the chamfer is 50°;

[0035] 2) Then use deionized water and absolute ethanol to ultrasonically clean 3~5 times respectively, the ultrasonic time for each cleaning is 50min, the ultrasonic power is 200W, and finally it is dried in an electric heating blast drying box at 70℃.

[0036] Step 2: Prepare SiC porous inner coating on the surface of C / C composite material by embedding method

[0037] 1) First, take commercially available analytically pure Si powder, C powder and WO with a particle size of 40~50μm 3 Powder, according to Si powder: C powder: WO 3 Powder=4:4:1.8 to prepare embedding powder, then put the pretreated carbon / carbon composite material into a graphite crucible and embed it in the embedding powder;

Embodiment 2

[0051] Step 1: C / C composite material pretreatment package:

[0052] 1) Take the 2D-carbon / carbon composite material used for aircraft brake pads and process it into 33×33×33mm 3 Cube, and polished and chamfered the surface, the chamfer is 55°;

[0053] 2) Then use deionized water and absolute ethanol to ultrasonically clean 3~5 times, each time the ultrasonic time is 65min, the ultrasonic power is 160W, and finally it is dried in an electric blast drying oven at 75℃.

[0054] Step 2: Prepare SiC porous inner coating on the surface of C / C composite material by embedding method

[0055] 1) First, take commercially available analytically pure Si powder, C powder and WO with a particle size of 40~50μm 3 Powder, according to Si powder: C powder: WO 3 Powder=3.5:5:2 to prepare embedding powder, then put the pretreated carbon / carbon composite material into a graphite crucible, and embed it in the embedding powder;

[0056] 2) Secondly, put the graphite crucible in a vertical vacuum furnace, p...

Embodiment 3

[0068] Step 1: C / C composite material pretreatment package:

[0069] 1) Take the 2D-carbon / carbon composite material used for aircraft brake pads and process it into 35×35×35mm 3 Cube, and polished and chamfered the surface, the chamfer is 60°;

[0070] 2) Then use deionized water and absolute ethanol to ultrasonically clean 3~5 times, each cleaning ultrasonic time is 80min, ultrasonic power is 180W, and finally dried in an electric heating blast drying oven at 80℃.

[0071] Step 2: Prepare SiC porous inner coating on the surface of C / C composite material by embedding method

[0072] 1) First, take commercially available analytically pure Si powder, C powder and WO with a particle size of 40~50μm 3 Powder, according to Si powder: C powder: WO 3 Powder=3:4.5:1.5 to prepare embedding powder, and then put the pretreated carbon / carbon composite material into a graphite crucible and embed it in the embedding powder;

[0073] 2) Secondly, put the graphite crucible into a vertical vacuum furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com