Comprehensive extraction and processing method of industrial wastewater

An industrial wastewater, comprehensive extraction technology, applied in heating water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc. , energy saving, considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

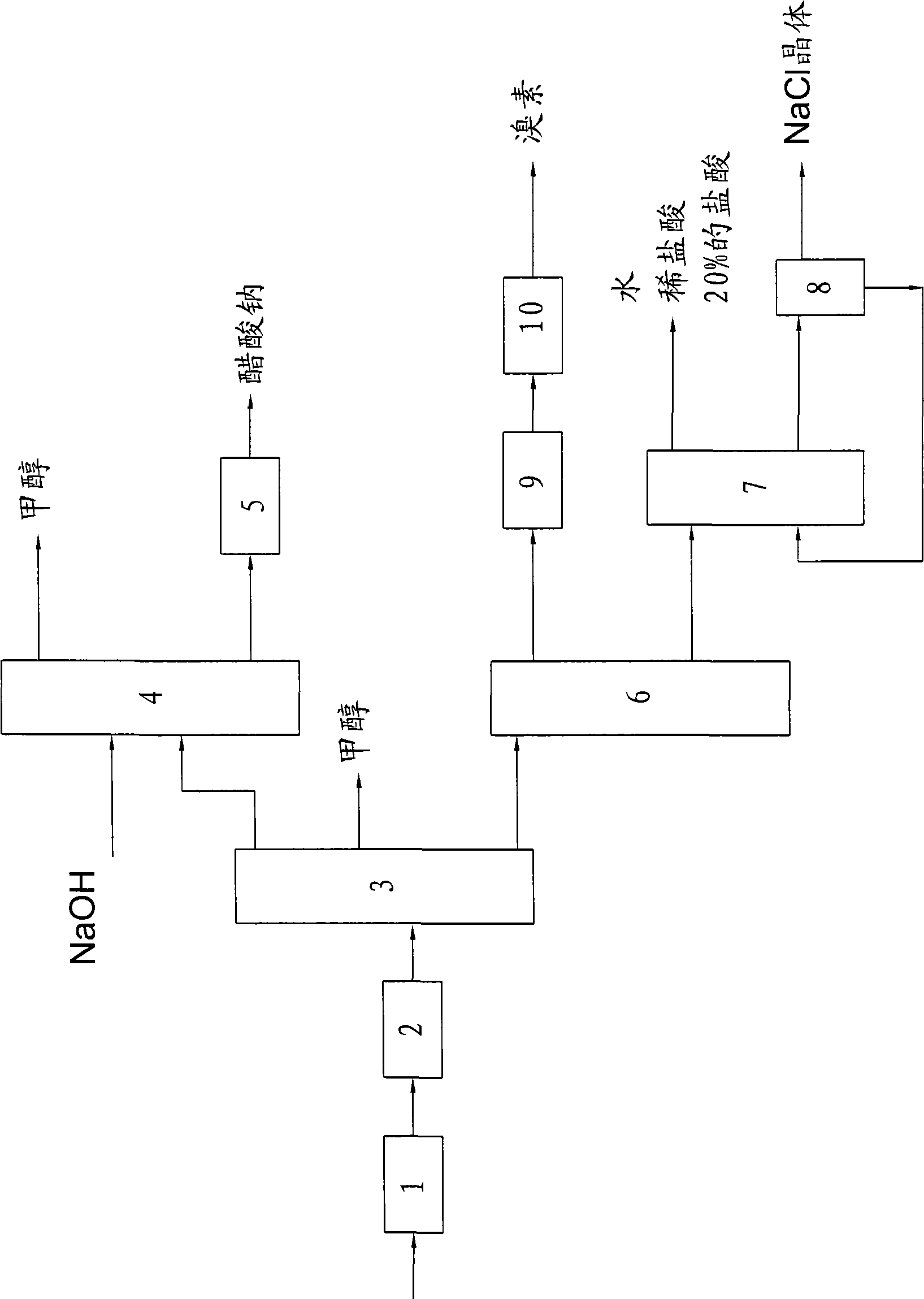

[0034] Embodiment: Taking the industrial wastewater containing sodium bromide, sodium acetate and methyl alcohol as an example, the treatment steps are as follows:

[0035] 1) Oxidation: In the oxidation kettle 1, at normal temperature, pass chlorine gas into the wastewater for oxidation until the pH is 7-0.5;

[0036] 2) esterification: then in esterification still 2, add industrial waste acid (hydrochloric acid) to carry out esterification reaction as catalyzer, waste acid add-on is 10wt% of waste water weight, in esterification still 2 internal esterification, the reaction time is 5-60 minutes, the reaction temperature is 55-65°C;

[0037] 3) Rectification: the reaction liquid in step 2) enters the middle part of the rectification tower 3, methyl acetate is fractionally distilled at the top of the tower at 55-58 °C, and methanol is separated at the upper middle part at 63-66 °C;

[0038] 4) Hydrolysis and distillation: Methyl acetate enters the hydrolysis and rectification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com