Method and system for extracting rubidium salt and cesium salt from mother liquor after extracting lithium from lepidolite

A technology for extracting lithium mother liquor and lepidolite, applied in chemical instruments and methods, rubidium/cesium/francium compounds, alkali metal compounds, etc., can solve problems such as difficult operation control, reduce impurities, improve metal recovery rate, The effect of high separation coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

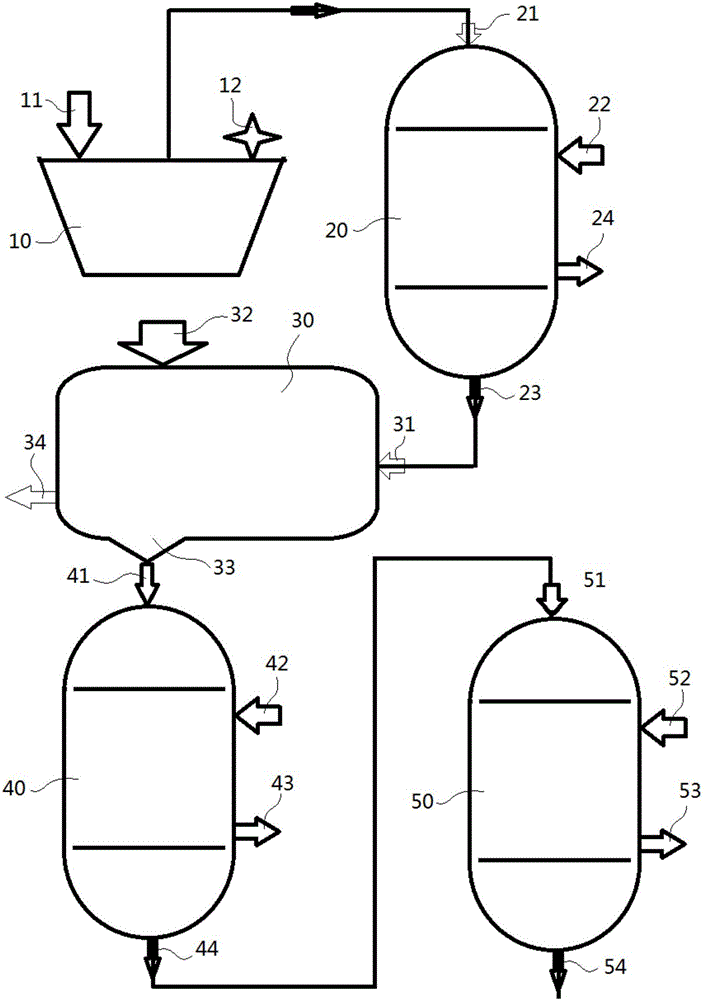

[0047] like figure 1 As shown, the system for extracting rubidium salt and cesium salt from lepidolite extracting lithium mother liquor according to the present invention comprises a pH value adjustment container 10, which is provided with a pH value adjustment agent adder 11, a pH value controller 12; extractor 20, It has lithium mica extraction mother liquor inlet 21, organic extractant additive 22, load organic phase I outlet 23, and raffinate outlet 24, extractor 20 can be made of PVC material; The organic extractant that adopts is p-xylene organic matter All contain potassium-sodium mixture in the raffinate; Scrubber 30, it has organic phase I inlet 31, water injection port 32, organic phase II outlet 33 and washing liquid discharge port 34; The first stripper 40, it has Loaded organic phase II inlet 41, stripping acid I inlet 42, rubidium salt stripping solution outlet 43, and organic phase outlet 44 of loaded cesium ions; the second stripper 50 has an organic phase inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com