Flexible transparent conductive graphene film and manufacturing method and application thereof

A graphene film, transparent and conductive technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of insufficient graphite oxide reduction process, difference in conductivity, general conductivity, etc., and achieve high conductivity , high conductivity, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

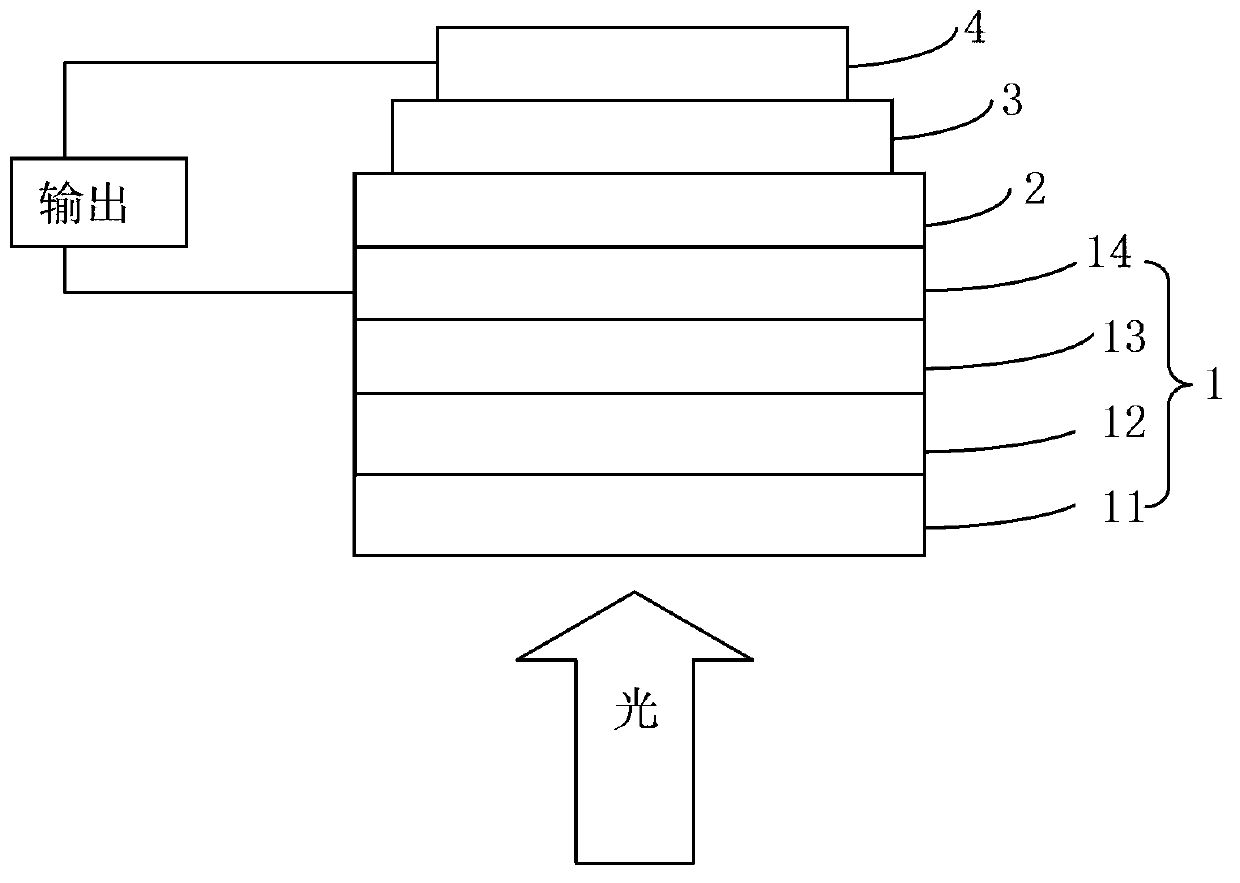

Embodiment 1

[0031] (1) Take a clean glass substrate with a thickness of 0.1mm and place it in a vapor deposition chamber, feed 600Pa of hydrogen gas, raise the temperature to 800°C, and then feed 500Pa of butane gas to deposit a graphene layer on the glass substrate, The thickness of graphene layer is 200nm, obtains the glass substrate with graphene layer;

[0032] (2) Place the glass substrate with the graphene layer in a vacuum of 10 -4 In the vacuum coating chamber of Pa, the nickel layer is prepared on the graphene layer by electron beam evaporation, and the electron beam energy is 100W / cm 2 , evaporation rate is 0.2nm / s, the thickness of nickel layer is 15nm; Obtain flexible transparent conductive graphene film P1, the structure of P1 is glass substrate / graphene (200nm) / nickel (15nm) / graphene (100nm).

Embodiment 2

[0034] A preparation method for a flexible transparent conductive graphene film, comprising the steps of:

[0035] (1) Take a clean glass substrate with a thickness of 2mm and place it in a vapor deposition chamber, pass in hydrogen gas of 1000Pa, heat up to 1000°C, and then pass in ethane gas of 1000Pa, and deposit a graphene layer on the glass substrate. The thickness of alkene layer is 200nm, obtains the glass substrate with graphene layer;

[0036] (2) Place the glass substrate with the graphene layer in a vacuum of 10 -5 In the vacuum coating chamber of Pa, the gold layer is prepared on the graphene layer by thermal resistance evaporation, the evaporation rate is 0.5nm / s, and the thickness of the gold layer is 15nm;

[0037] (3) Repeat the method described in steps (1) and (2) to prepare the graphene layer and the gold layer, so that the number of layers of the gold layer is 2 layers, and a flexible transparent conductive graphene film P2 is obtained, and the structure o...

Embodiment 3

[0039] A preparation method for a flexible transparent conductive graphene film, comprising the steps of:

[0040] (1) Take a clean glass substrate with a thickness of 1mm and place it in a vapor deposition chamber, pass in 500Pa of hydrogen gas, heat up to 800°C, and then pass in 500Pa of propane gas to deposit a graphene layer on the glass substrate, graphene The thickness of layer is 100nm, obtains the glass substrate with graphene layer;

[0041] (2) Place the glass substrate with the graphene layer in a vacuum of 10 -4 In the vacuum coating chamber of Pa, the platinum layer is prepared on the graphene layer by electron beam evaporation, and the electron beam energy is 10W / cm 2 , the evaporation rate is 0.01nm / s, and the thickness of the platinum layer is 10nm;

[0042](3) Repeat the method described in steps (1) and (2) to prepare a graphene layer and a platinum layer, so that the number of layers of the platinum layer is 3 layers, and a flexible transparent conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com