High efficiency oil stain removal cleaning agent and preparation method thereof

A technology for removing oil stains and cleaning agents, applied in the field of cleaning agents, can solve the problems of difficulty in cleaning, affecting the life, and destroying the surface of oil stains, and achieves the effects of good cleaning effect, simple preparation method, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

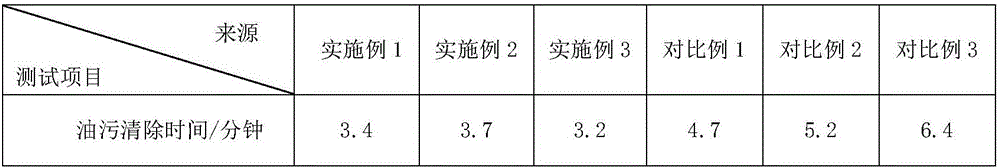

Embodiment 1

[0021] A high-efficiency degreasing cleaning agent, which consists of: sodium dodecylbenzenesulfonate 9.6kg, fatty alcohol polyoxyethylene ether sodium sulfate 3.6kg, lauryl alcohol polyoxyethylene ether 2.4kg, anhydrous sodium metasilicate 3.2kg kg, sodium bentonite 1.68kg, calcium bentonite 2.52kg, sodium carbonate 2.4kg, methyl acrylate 0.4kg, sodium percarbonate 1.8kg and water 68kg.

[0022] The preparation method of described high-efficiency degreasing cleaning agent is:

[0023] S1: Dissolve sodium dodecylbenzenesulfonate and sodium fatty alcohol polyoxyethylene ether sulfate in water, heat to 42°C, add polyoxyethylene lauryl ether and stir evenly, and cool to room temperature;

[0024] S2: Add sodium-based bentonite, calcium-based bentonite, sodium percarbonate, methyl acrylate, anhydrous sodium metasilicate and sodium carbonate to the mixture obtained in step S1 in sequence; stir evenly.

Embodiment 2

[0026] A high-efficiency degreasing cleaning agent, which consists of: sodium dodecylbenzenesulfonate 6.3kg, fatty alcohol polyoxyethylene ether ammonium sulfate 5.3kg, lauryl alcohol polyoxyethylene ether 1.5kg, anhydrous sodium metasilicate 2.7kg kg, sodium bentonite 1.4kg, calcium bentonite 2.1kg, sodium carbonate 3.1kg, methyl acrylate 0.7kg, sodium perborate 1.5kg and water 55kg.

[0027] The preparation method of described high-efficiency degreasing cleaning agent is:

[0028] S1: Dissolve sodium dodecylbenzenesulfonate and fatty alcohol polyoxyethylene ether ammonium sulfate in water, heat to 45°C, add lauryl alcohol polyoxyethylene ether and stir evenly, and cool to room temperature;

[0029] S2: Add sodium-based bentonite, calcium-based bentonite, sodium perborate, methyl acrylate, anhydrous sodium metasilicate and sodium carbonate to the mixture obtained in step S1 in sequence; stir evenly.

Embodiment 3

[0031] A high-efficiency degreasing cleaning agent, which consists of: sodium dodecylbenzenesulfonate 8.5kg, fatty alcohol polyoxyethylene ether sodium sulfate 3.6kg, fatty alcohol polyoxyethylene ether ammonium sulfate 1.2kg, lauryl alcohol polyoxyethylene Ether 1.8kg, anhydrous sodium metasilicate 2.9kg, sodium bentonite 1.6kg, calcium bentonite 2.4kg, sodium carbonate 2.7kg, methyl acrylate 0.51kg, sodium percarbonate 0.54kg, sodium perborate 1.08kg and water 59kg .

[0032] The preparation method of described high-efficiency degreasing cleaning agent is:

[0033] S1: Dissolve sodium dodecylbenzenesulfonate, sodium fatty alcohol polyoxyethylene ether sulfate and ammonium fatty alcohol polyoxyethylene ether sulfate in water, heat to 43°C, add lauryl alcohol polyoxyethylene ether and stir evenly, cool to room temperature;

[0034] S2: Add sodium-based bentonite, calcium-based bentonite, sodium percarbonate, sodium perborate, methyl acrylate, anhydrous sodium metasilicate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com