Solvothermal preparation method of cobalt nano-fibers

A cobalt nano and solvothermal technology, applied in nanotechnology and other directions, can solve the problems of poor flexibility and uneven diameter, and achieve the effects of good flexibility, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of reaction solution

[0023] Prepare the precursor solution with ethylene glycol as the solvent, and the concentration of each reactant is as follows:

[0024]

[0025] 2. Preparation of cobalt nanofibers

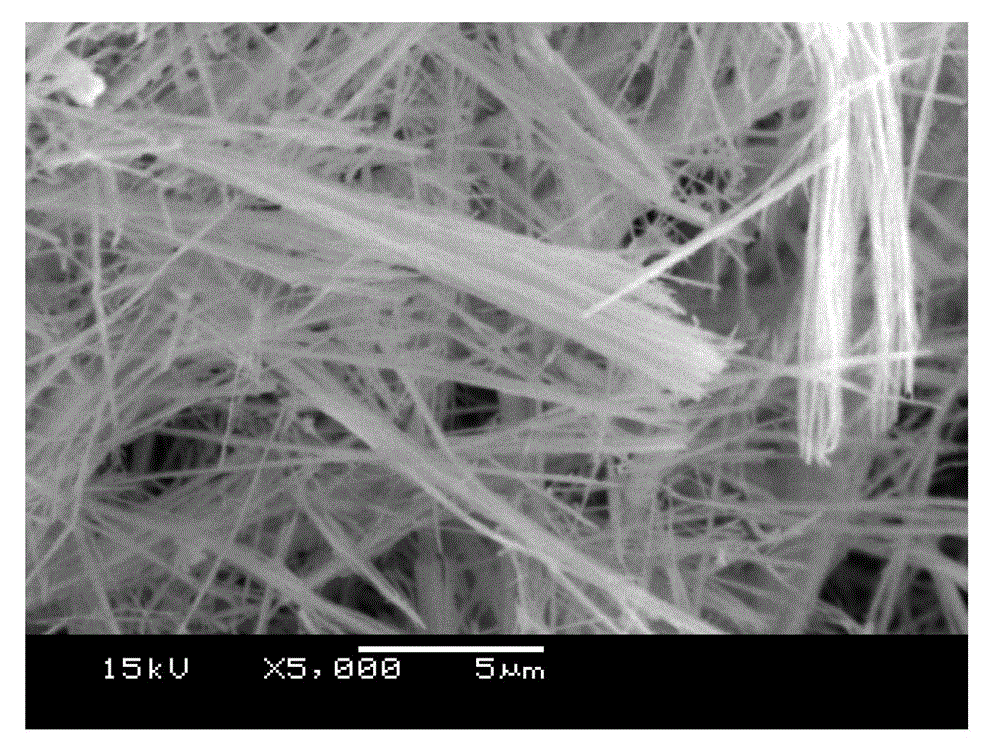

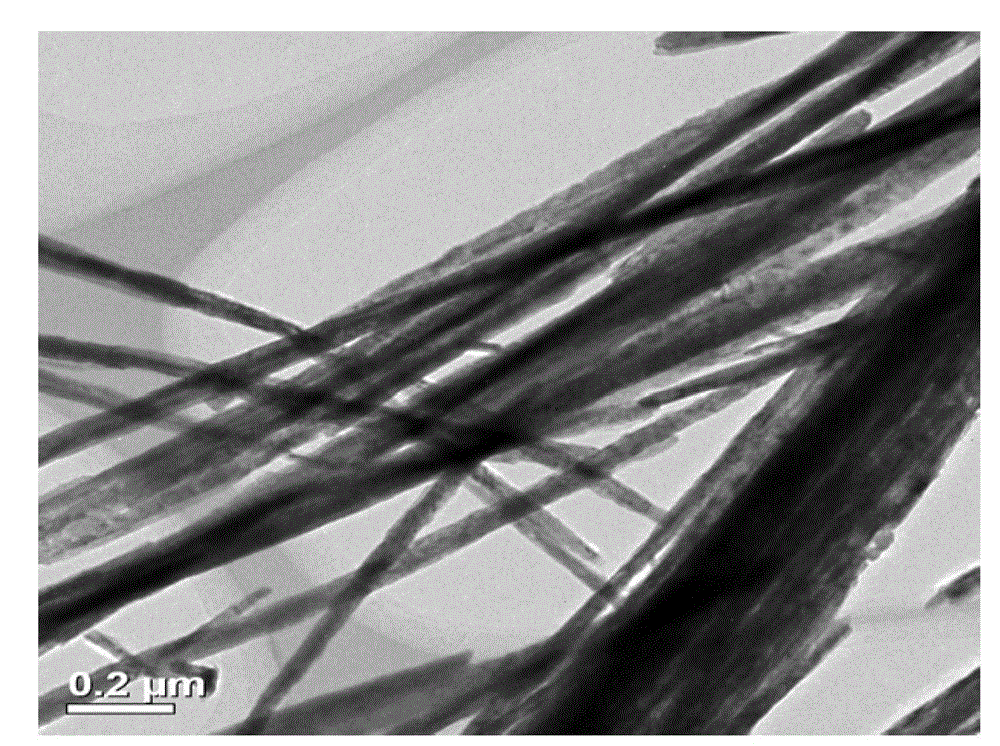

[0026] Move the above solution into the reaction kettle with a filling degree of 50%, tighten the lid of the reaction kettle, place it in a heating furnace, heat it to 180°C, and keep it warm for 36 hours. After the reaction kettle is completely cooled, open it and centrifuge the resulting black precipitate. After separation, it was washed three times with absolute ethanol, and then dried at 50°C for 24 hours. The SEM photo of the resulting product is as figure 1 As shown, the TEM photographs are as figure 2 shown.

Embodiment 2

[0028] 1. Preparation of reaction solution

[0029] Prepare the precursor solution with ethylene glycol as the solvent, and the concentration of each reactant is as follows:

[0030]

[0031] 2. Preparation of cobalt nanofibers

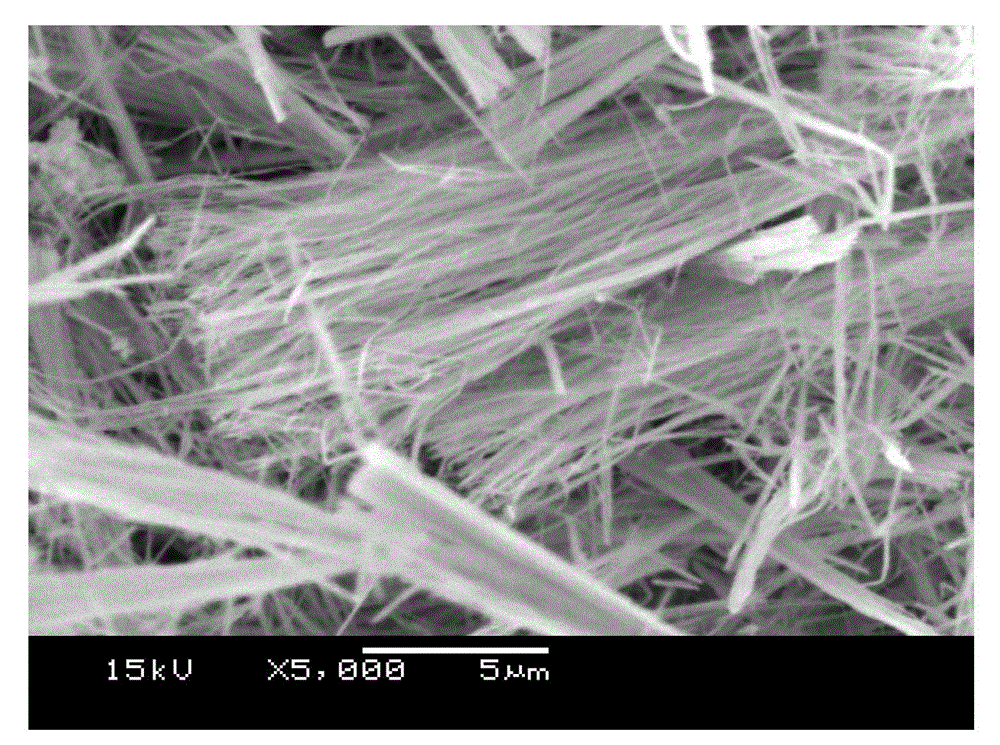

[0032] Move the above solution into the reaction kettle with a filling degree of 70%. Tighten the lid of the reaction kettle and place it in a heating furnace to heat to 190°C and keep it warm for 24 hours. After the reaction kettle is completely cooled, open it and centrifuge the resulting black precipitate. After separation, it was washed three times with absolute ethanol, and then dried at 50°C for 24 hours. The SEM picture of the resulting product is as image 3 As shown, the X-ray diffraction spectrum is shown as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com