Paint for electrical equipment and preparation process of paint

A technology for power equipment and coatings, applied in anti-corrosion coatings, coatings, etc., can solve problems such as potential safety hazards, easy corrosion, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A coating for electrical equipment, which is prepared from the following raw materials in parts by weight:

[0023] 30 parts of polyvinylpyrrolidone, 25 parts of vinyltrimethoxysilane, 18 parts of emulsified silicone oil, 15 parts of polyoxyethylene lauryl ether, 12 parts of phthalates, 8 parts of silicon carbide, 6 parts of lithium bentonite, nano 2 parts of silica gel and 1 part of nano titanium dioxide.

[0024] The preparation method of above-mentioned coating comprises the steps:

[0025] 1) Weigh each raw material according to parts by weight for later use

[0026] 2) Add polyvinylpyrrolidone, vinyltrimethoxysilane, emulsified silicone oil, polyoxyethylene lauryl ether and phthalate to the reactor in sequence, and stir at 500 rpm for 3 minutes to obtain the main ingredient;

[0027] 3) Send silicon carbide and lithium-based bentonite to a ball mill, and grind them to a powder with a particle size of 500 mesh, which is the auxiliary material;

[0028] 4) Put nan...

Embodiment 2

[0032] A coating for electrical equipment, which is prepared from the following raw materials in parts by weight:

[0033] 40 parts of polyvinylpyrrolidone, 28 parts of vinyltrimethoxysilane, 22 parts of emulsified silicone oil, 20 parts of polyoxyethylene lauryl ether, 14 parts of phthalates, 10 parts of silicon carbide, 8 parts of lithium bentonite, nano 3 parts of silica gel and 2 parts of nano titanium dioxide.

[0034] The preparation method of above-mentioned coating comprises the steps:

[0035] 1) Weigh each raw material according to parts by weight for later use

[0036] 2) Add polyvinylpyrrolidone, vinyltrimethoxysilane, emulsified silicone oil, polyoxyethylene lauryl ether and phthalate to the reactor in sequence, and stir at 500 rpm for 5 minutes to obtain the main ingredient;

[0037] 3) Send silicon carbide and lithium-based bentonite to a ball mill, and grind them to a powder with a particle size of 600 mesh, which is the auxiliary material;

[0038] 4) Put n...

Embodiment 3

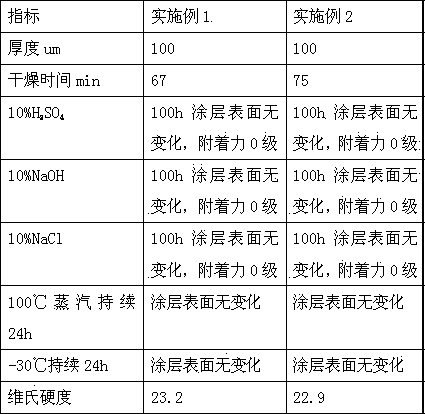

[0043] Taking the cable material as an example, paint the coatings prepared in Example 1 and Example 2 on the outer layer of the cable, and measure the performance parameters of the cable surface, see Table 1 for details:

[0044] Table 1

[0045]

[0046] Conclusion: the coatings prepared in Example 1 and Example 2 of the present invention have better properties, can effectively prevent the corrosion of acid-base salts, and have better high temperature resistance and mechanical properties; the coatings of the present invention improve the performance of power materials. The service life reduces potential safety hazards; the preparation process of the coating of the invention is simple and convenient, and the application method is simple.

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com