Method for determining starch content in tobacco

A starch content, tobacco technology, applied in the direction of material analysis by observing the effect of chemical indicators, and analysis by chemical reaction of materials, etc., can solve problems such as erosion of eyes, reduction of pipeline service life, perchloric acid ingress, etc. , to achieve the effect of saving experimental costs and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

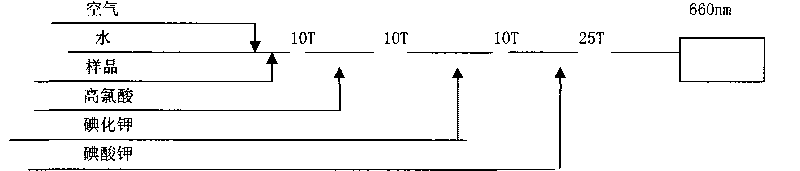

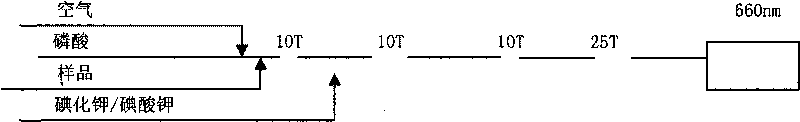

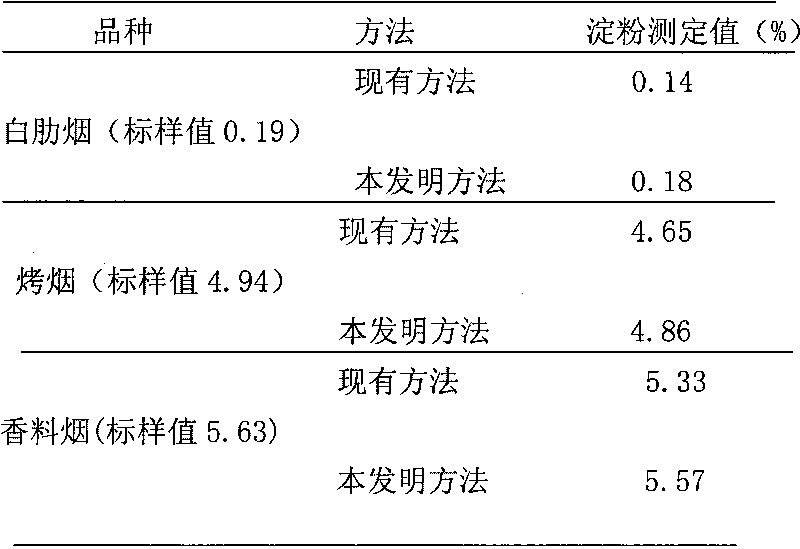

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is further described below in conjunction with an embodiment.

[0016] The method for detecting starch content in tobacco provided by the present embodiment comprises the following specific steps:

[0017] a. Weigh 0.1g of the tobacco sample that was dried at 40°C and crushed through a 0.45mm mesh sieve, put it into a 100ml beaker, add 80ml of distilled water and boil for 40min, after cooling, move it into a 100ml volumetric flask, use distilled water to make up volume, shake well, and filter. Prepare sample reagents;

[0018] b. With 140ul, 85% phosphoric acid, the volume was adjusted to 1000ml with distilled water, and 32 drops of 22% polyoxyethylene lauroyl ether reagent were added to prepare the phosphoric acid reagent;

[0019] C, take by weighing 1g potassium iodate and 10g potassium iodide and make it to 1000ml with distilled water, add 32 drops of 22% polyoxyethylene lauroyl ether reagent, prepare potassium iodide / potassium iodate reagent;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com