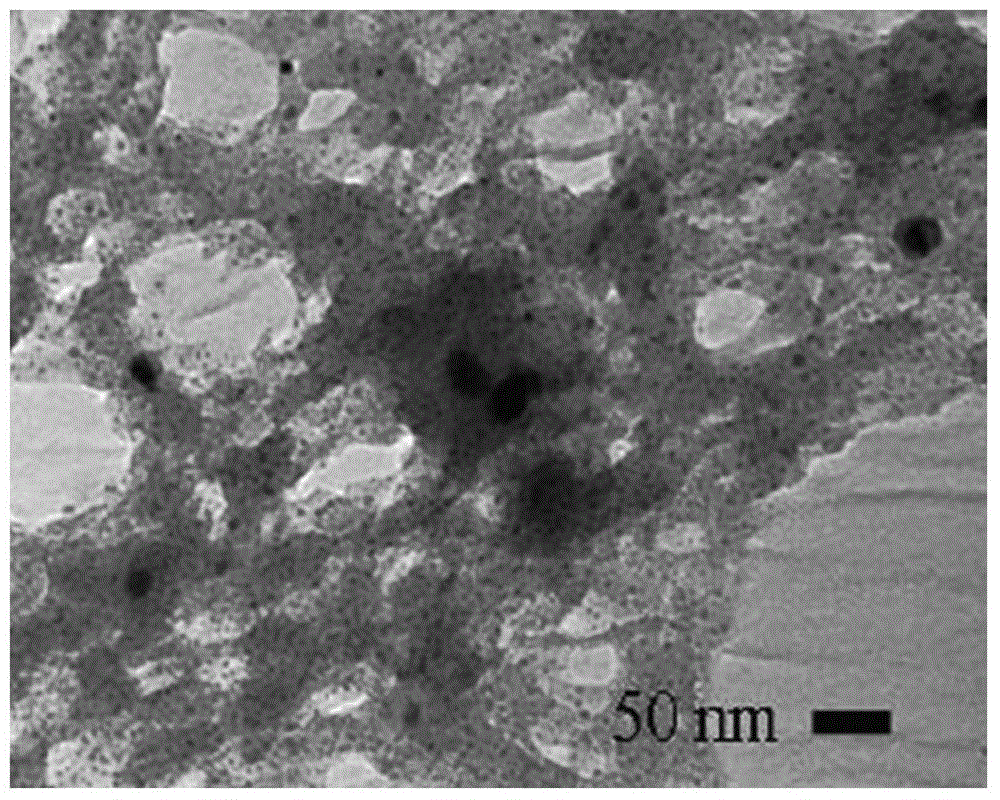

Preparation method for chrysanthemum synthetic nanometer zero-valent iron suspension liquid

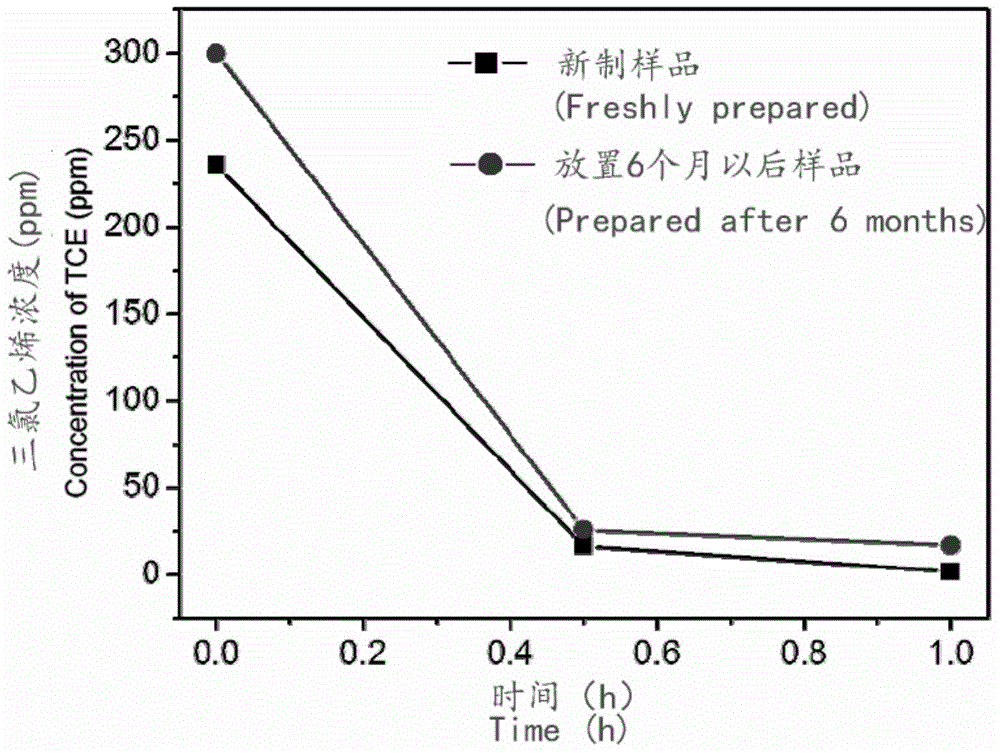

A nano-zero-valent iron and suspension technology, which is applied in the field of preparation of nano-zero-valent iron suspension synthesized by chrysanthemums, can solve problems such as flocculation and precipitation, and achieve the effects of stable suspension, low energy consumption, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment one: a kind of preparation method of chrysanthemum synthetic nano-zero valent iron suspension, the steps are as follows:

[0021] 1) Collect fresh chrysanthemums of the Chrysanthemum family and dry them at 70 degrees Celsius for 90 hours to obtain dried chrysanthemums. Immerse the dried chrysanthemums in water at 55 degrees Celsius. The ratio of dried chrysanthemums to water is 7 g / L, and then add a small amount of Methanol, the volume ratio of water and methanol is: 1: 0.005, soaks 50 minutes, obtains primary chrysanthemum solution;

[0022] 2) Then pass the chrysanthemum solution through a sieve of no less than 200 mesh for primary filtration to obtain the primary filtrate;

[0023] 3) Filtrate the primary filtrate through a vacuum negative pressure filter with a filter membrane of not less than 0.49 microns to obtain the chrysanthemum extract;

[0024] 4) Then add ferric chloride aqueous solution with a molar concentration of 0.40 mol / L to the chrysanthem...

Embodiment 2

[0025] Embodiment two: a kind of preparation method of chrysanthemum synthetic nano-zero valent iron suspension is characterized in that the steps are as follows:

[0026] 1) Collect fresh chrysanthemums of the Chrysanthemum family and dry them at 80 degrees Celsius for 75 hours to obtain dried chrysanthemums. Immerse the dried chrysanthemums in water at 85 degrees Celsius. The ratio of dried chrysanthemums to water is 15 grams per liter, and then add A small amount of ethanol, the volume ratio of water and ethanol is: 1: 0.01, soaks 100 minutes, obtains primary chrysanthemum solution;

[0027] 2) Then pass the chrysanthemum solution through a sieve of no less than 200 mesh for primary filtration to obtain the primary filtrate;

[0028] 3) Filtrate the primary filtrate through a vacuum negative pressure filter with a filter membrane of not less than 0.49 microns to obtain the chrysanthemum extract;

[0029] 4) Then add an aqueous ferric nitrate solution with a molar concentra...

Embodiment 3

[0031] Embodiment three: a kind of preparation method of chrysanthemum synthetic nano-zero valent iron suspension, is characterized in that the steps are as follows:

[0032] 1) Collect fresh chrysanthemums of the Chrysanthemum family and dry them at 85 degrees Celsius for 25 hours to obtain dried chrysanthemums. Immerse the dried chrysanthemums in water at 60 degrees Celsius. The ratio of dried chrysanthemums to water is 23 grams per liter, and then add A small amount of ethylene glycol, the volume ratio of water and ethylene glycol is: 1: 0.09, soak for 160 minutes, obtain primary chrysanthemum solution;

[0033] 2) Then pass the chrysanthemum solution through a sieve of no less than 200 mesh for primary filtration to obtain the primary filtrate;

[0034] 3) Filtrate the primary filtrate through a vacuum negative pressure filter with a filter membrane of not less than 0.49 microns to obtain the chrysanthemum extract;

[0035] 4) Then add ferric chloride aqueous solution wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com