Combined treatment method for used water glass sand reclamation and reclamation treating liquid concentration

A technology for regenerating treatment liquid and old sand, which is applied in the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc. High temperature performance of molding (core) sand, increased sewage and treatment costs, etc., to achieve the effect of saving resources, less energy consumption, and less water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

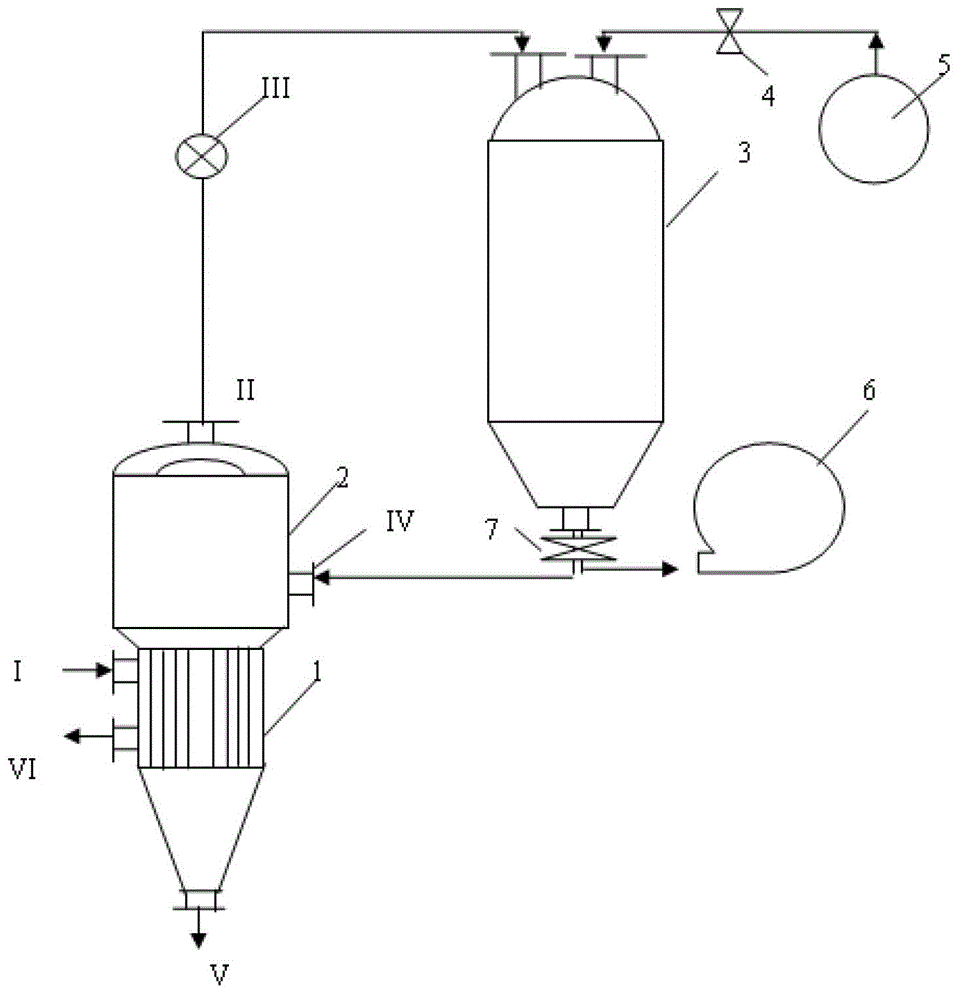

[0024] Add water glass old sand regeneration treatment liquid into the evaporation chamber of the concentration device, put the water glass old sand into the evaporation chamber of the water glass old sand regeneration device; feed water vapor at 100°C and above into the evaporation chamber of the concentration device, The water glass old sand regeneration treatment liquid is heated, evaporated and concentrated; the secondary steam discharged from the concentration device is passed into the water glass old sand regeneration device, and the amount of the secondary steam is more than 5% of the water glass old sand quality, preferably 5% %-30%, which not only ensures the steaming effect, but also prevents excessive heat energy consumption. Spray and rinse the old water glass sand after passing through the steam, and the amount of water used for washing is 30%-100% of the mass of the old sand, so as to obtain reclaimed water glass sand. Preferably, the water consumption for rinsin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com