Trentment method of tin copper slag

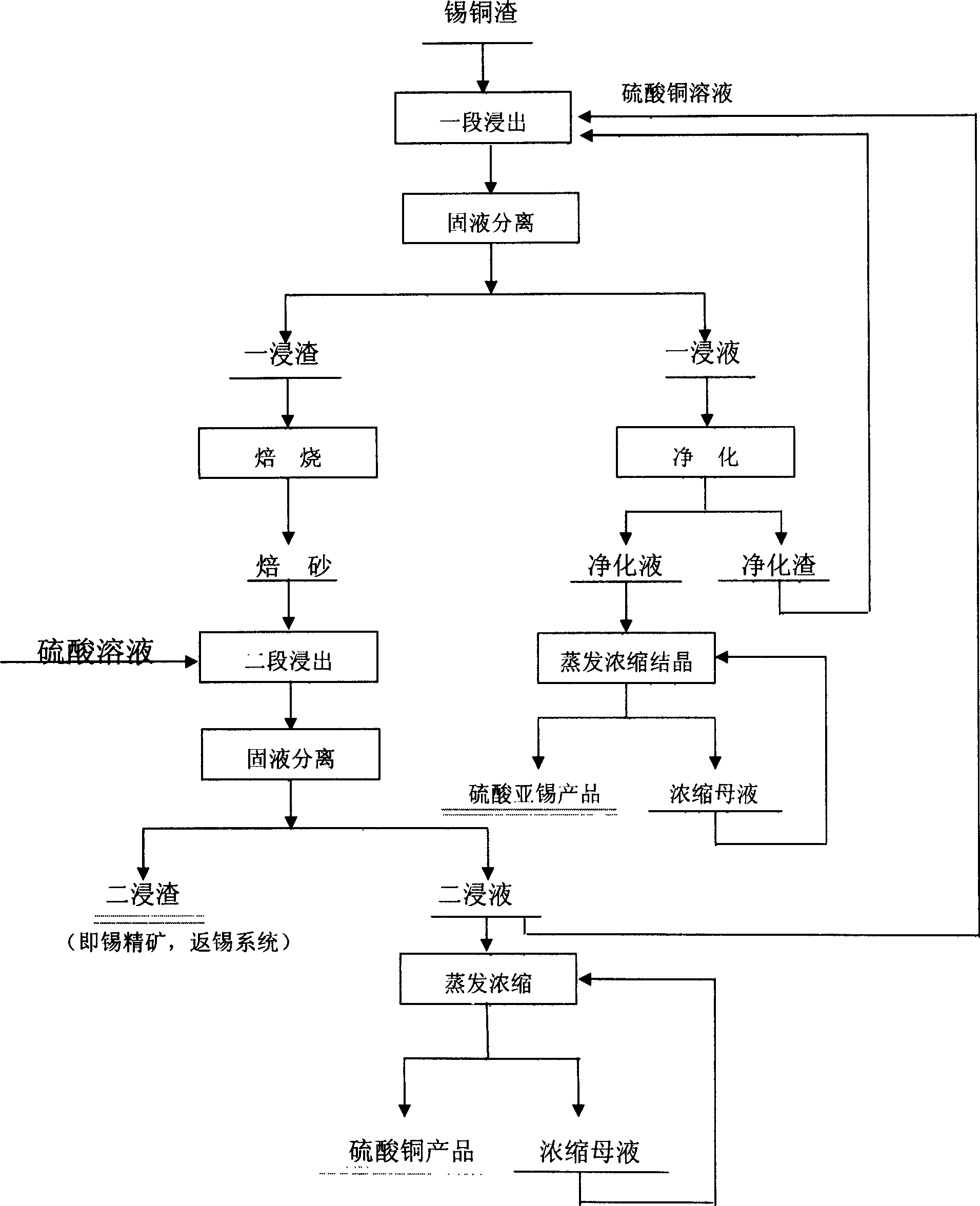

A slag treatment, tin-copper technology, applied in the field of combined fire-wet treatment of tin-copper slag, can solve the problems of long process flow, high treatment cost, poor economic benefits, etc., achieve simple and feasible process, good environmental effect and low production cost Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Take 6kg of tin-copper slag with the following composition, and use 30L to contain Cu 2+ 40g / l CuSO 4 The solution was leached under normal pressure for 3 hours at a temperature of 85-90°C and a liquid-solid ratio of 5:1 to obtain 28L of stannous sulfate solution containing Sn 58.04g / l, Cu<0.001g / l and 6.1kg of leaching residue.

[0025] Cu

[0026] Above-mentioned stannous sulfate solution obtains 2.5kg of stannous sulfate product after evaporation concentration, crystallization by cooling, and product quality is as follows.

[0027] SnSO 4

[0028] The above-mentioned leaching slag was oxidized and roasted at 700°C for 2 hours, and the calcined sand obtained was 120g / lH 2 SO 4 Solution 30L was leached at 85°C for 1 hour to obtain 29L copper sulfate solution containing Cu71.18g / l and 3.6kg leaching residue (tin concentrate) containing Cu1.24% and Sn62%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com