Method for carrying water treatment by active carbon fiber-ozone oxidization combination

A technology of activated carbon fiber and ozone oxidation, which is applied in the direction of oxidation water/sewage treatment, adsorption water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., and can solve the problem of reduced degradation performance of activated carbon, low pertinence of special water sources, and process conditions and complex equipment, etc., to achieve the effect of increasing ozone utilization rate, improving ozonation efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the modification treatment of active carbon fiber

[0024] Put it into the carbonization activation furnace for secondary activation to expand its pore size to adjust the pore structure of the activated carbon, and modify the surface of the carbon by acid-base treatment. During the activation process, pass nitrogen gas as a protective gas, and when the temperature rises to 800°C, pass water vapor to activate for 40 minutes. In addition to water vapor, you can also choose carbon dioxide, ammonia, magnesium nitrate, iron nitrate and other metal salts as activators, either using one of the activators for activation, or using two activators in combination. activation. Because the molecular diameter of phenolic compounds in wastewater is in the range of 0.7-1nm, only the pore size on the surface of activated carbon is larger than 1nm can efficiently adsorb these organic substances. Therefore, the purpose of activation is to expand the pore size of the activat...

Embodiment 2

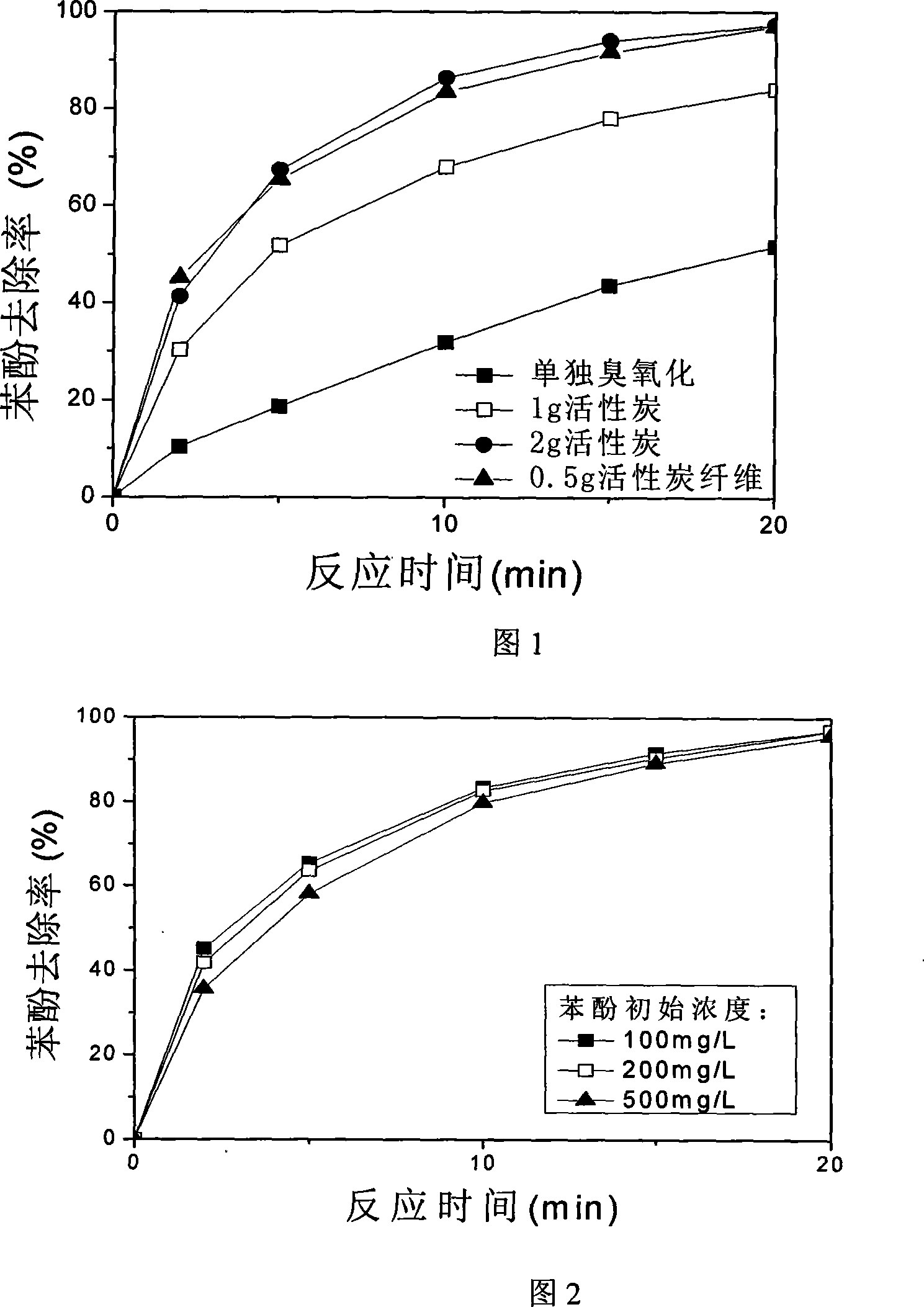

[0025] Embodiment 2: Utilize the high efficiency of degrading phenolic compound waste water after the activated carbon fiber in embodiment 1 is modified.

[0026] The device for catalytic ozonation of active carbon fiber to degrade organic pollutants in water is an ozonation reactor with sand core and air distribution. The gas source can be compressed air or oxygen, which enters the ozone generator after drying and filtering. The gas distribution device of the ozone reactor is a sand core at the bottom. When the ozonated gas passes through, tiny bubbles are generated to accelerate the dissolution of the gas phase ozone molecules into the water. In order to ensure better fluidization of activated carbon fibers in the ozone reactor, so as to fully contact with phenolic substances in water and dissolved ozone, activated carbon fibers are cut into blocks of different sizes according to the diameter of the reactor. The presence of activated carbon fibers increases the residence ti...

Embodiment 3

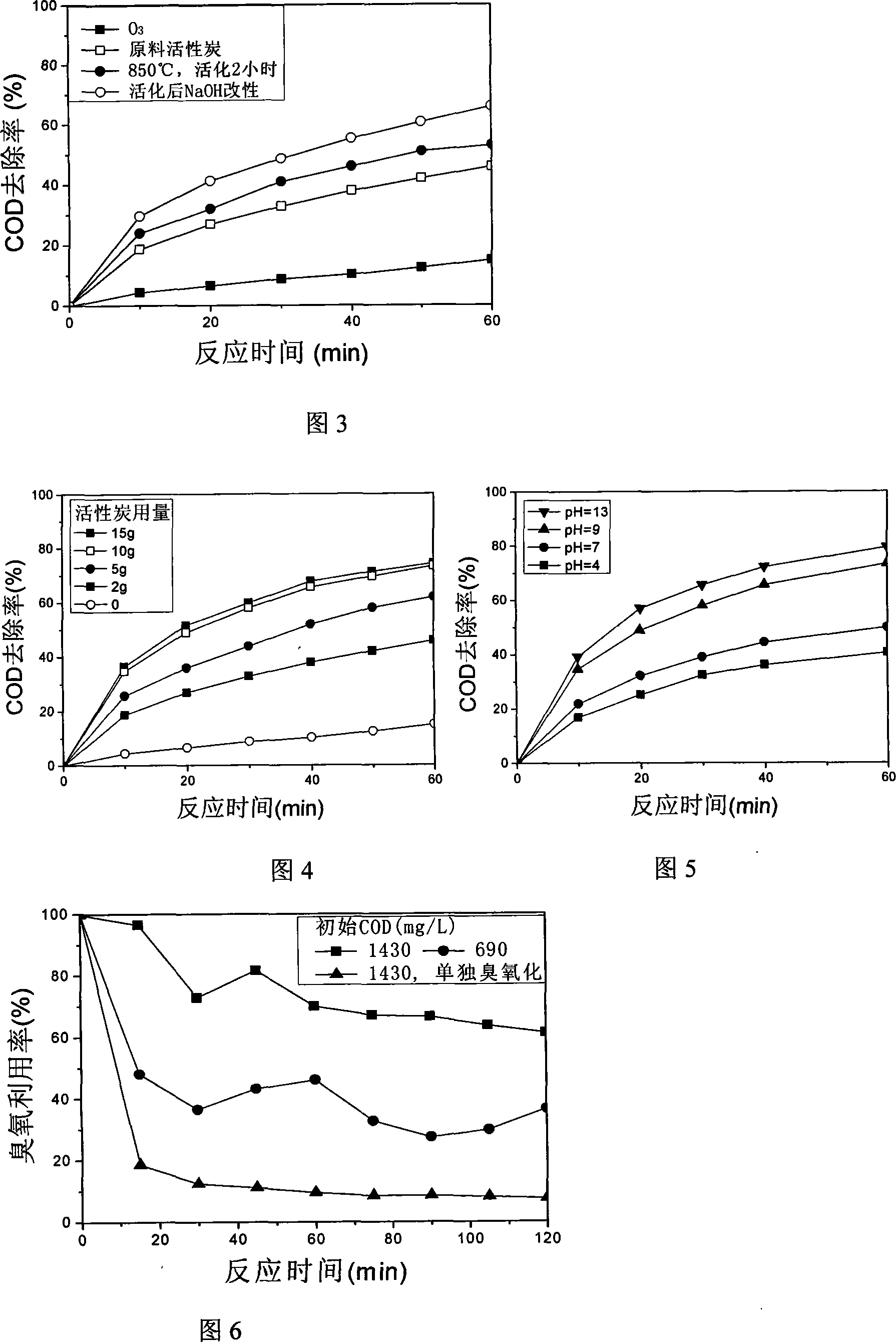

[0030] Embodiment 3: Utilize the high efficiency of degrading polyoxyethylene fatty alcohol ether wastewater after the activated carbon fiber in embodiment 1 is modified.

[0031]The flocculants of polyaluminum chloride and polyferric sulfate are added to flocculate and settle the suspended solids in the wastewater, and at the same time, part of the organic matter can be removed. According to the different flocculation effects of various flocculants, there are different dosages. Taking polyaluminum chloride as an example, according to the content of organic matter in water, the amount of flocculant added is 200-800mg / L, which can remove 10-18% of organic matter in water. The addition of flocculant has an optimal amount, too much or too little will make the flocculation effect worse.

[0032] The device for degrading organic pollutants in water by ozonation of activated carbon fiber is an ozonation reactor with sand core and air distribution. The gas source can be compressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com