Polymer thin film containing ion liquid and preparing method thereof

A polymer film and ionic liquid technology, applied in the field of polymer film and its preparation, can solve the problems of ionic liquid loss, limited interaction force, change of physical and chemical properties, etc., and achieve low cost, simple operation and wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

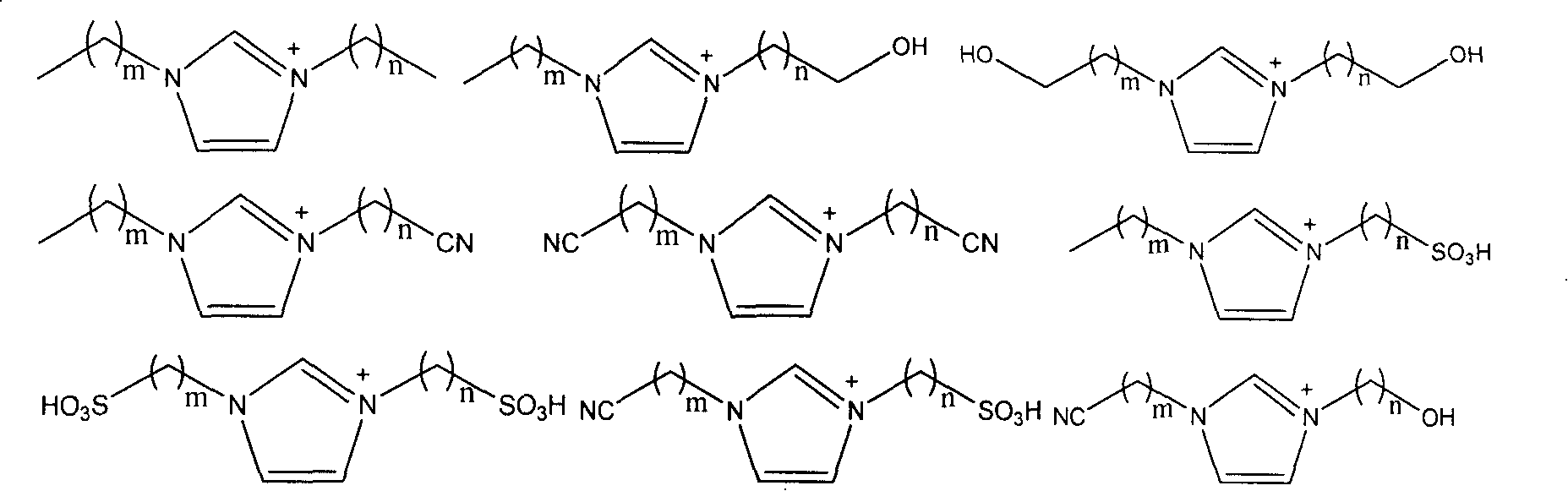

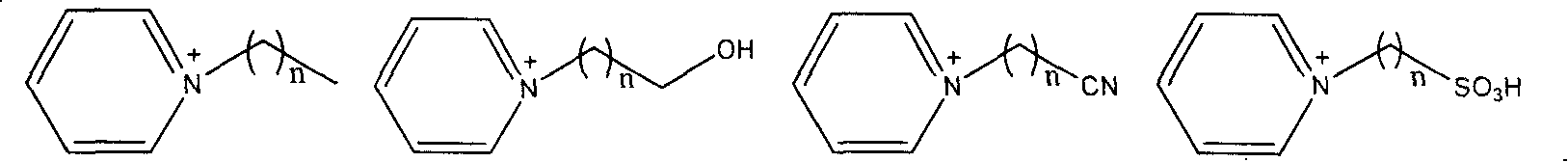

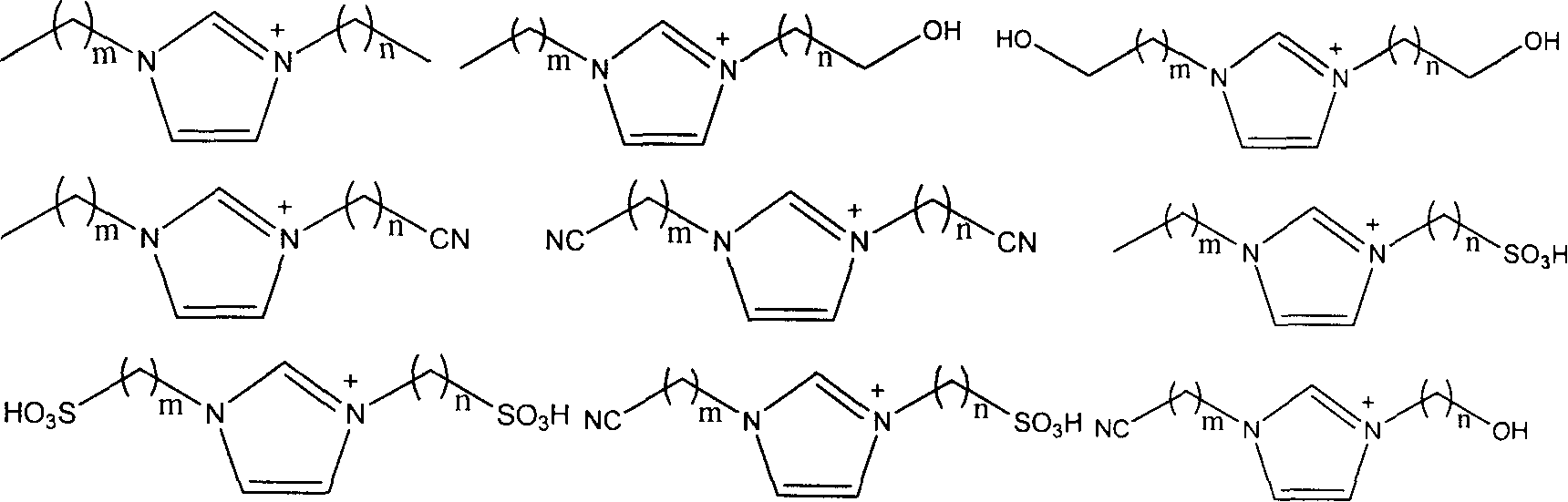

Method used

Image

Examples

Embodiment 1

[0025] Take 3g of PVA (molecular weight 13000-23000) in a 100ml Erlenmeyer flask, add 47ml of distilled water, heat to 80°C, weigh 1ml of 1-methyl-3-butylimidazolium fluoroborate ionic liquid, and quickly transfer to PVA In the aqueous solution, heat at 80°C for 8 hours, cool down to room temperature, coat the uniform solution on a stainless steel plate, dry at room temperature to form a film, and place it in a desiccator. The ionic liquid accounts for 30% of the film weight. A 10% (V / V) glutaraldehyde solution in acetone was prepared, sprayed onto the prepared film, cross-linked for 30 min, and dried to obtain a cross-linked film.

Embodiment 2

[0027] Take 3g of PVA (molecular weight 13000-23000) in a 100ml Erlenmeyer flask, add 47ml of distilled water, heat to 75°C, weigh 1ml of 1-methyl-3-octylimidazolium fluoroborate ionic liquid, and quickly transfer to PVA In the aqueous solution, heat at 75°C for 8h. Cool down to room temperature, coat the uniform solution on a stainless steel plate, dry at room temperature to form a film, and place it in a desiccator. The ionic liquid accounts for 30% of the film weight. A 10% (V / V) glutaraldehyde solution in acetone was prepared, sprayed onto the prepared film, cross-linked for 30 min, and dried to obtain a cross-linked film.

Embodiment 3

[0029] Take 3g of PVA (molecular weight 13000-23000) in a 100ml Erlenmeyer flask, add 47ml of distilled water, heat to 60°C, weigh 1ml of 1-methyl-3-butylsulfonate imidazolium fluoroborate ionic liquid, and quickly transfer Into the PVA aqueous solution, heated at 60°C for 9h, then cooled to room temperature, coated the uniform solution on a stainless steel plate, dried at room temperature to form a film, and placed in a desiccator. The ionic liquid accounted for 30% of the film weight. A 10% (V / V) glutaraldehyde solution in acetone was prepared, sprayed onto the prepared film, cross-linked for 30 min, and dried to obtain a cross-linked film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com