Absorption liquid for gas desulfurization and its application

A technology for absorbing liquid and gas, applied in the field of absorbing liquid, can solve the problems of clogging the absorption tower, slow catalyst regeneration rate and high degradation rate, and achieve the effect of less side reactions, overcoming slow regeneration rate and low degradation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

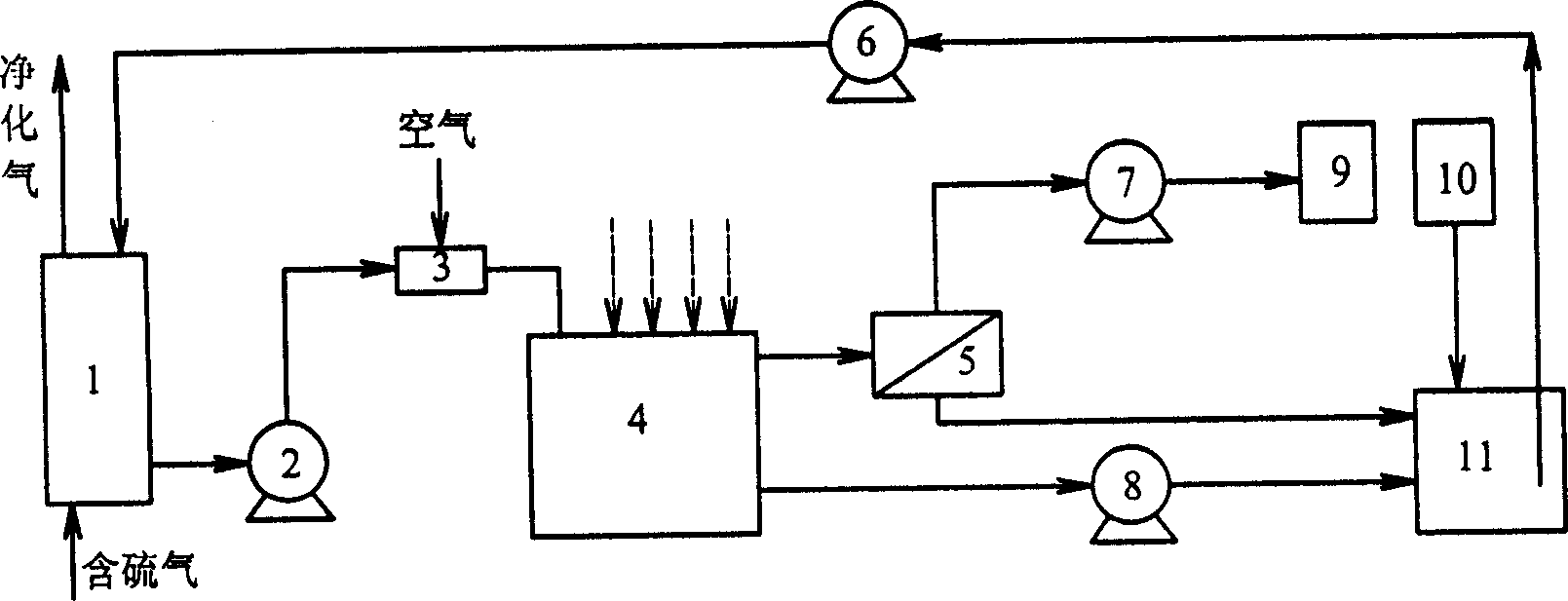

Image

Examples

Embodiment 1

[0032] Prepare gas desulfurization absorption liquid, its composition and content are: sodium carbonate 0.5mol / L, nanometer α-type iron oxide with a diameter of 20-30nm 0.01mol / L, iron fulvic acid 0.01mol / L, methanol 0.05mol / L L, dimethyl sulfoxide 0.01mol / L, the balance is water. The preparation method is simple mixing.

[0033] Use the prepared absorption liquid to remove sulfur in the gas, the specific method is as follows:

[0034] (1) Enter the prepared absorption liquid from the upper part of the absorption tower at a flow rate of 100L / hr, containing 1g / m 3 The hydrogen sulfide nitrogen gas is introduced from the lower part of the absorption tower at a flow rate of 2000L / hr, the gas and liquid flow in reverse, the purified gas is released from the top of the tower, and the absorption liquid flows out from the tower kettle; the temperature of the absorption tower is 30°C, and the pressure is 1 atmosphere;

[0035] (2) The absorption liquid flowing out of the tower kettl...

Embodiment 2

[0042] Prepare gas desulfurization absorption liquid, its composition and content are: sodium carbonate 1mol / L, nanometer α-type iron oxide with a diameter of 30-35nm 0.001mol / L, fulvic acid iron 0.1mol / L, methanol 0.1mol / L , dimethyl sulfoxide 0.05mol / L, and the balance is water. The preparation method is simple mixing.

[0043] Adopt the prepared absorbing liquid to carry out gas desulfurization according to the same method as in Example 1, the difference is that the raw material gas contains 2g / m 3 Hydrogen sulfide nitrogen, the gas flow rate is 1800L / hr.

[0044] The sulfur content in the purified gas was analyzed, and the analysis results are listed in Table 1.

Embodiment 3

[0046] Prepare gas desulfurization absorption liquid, its composition and content are: 0.05mol / L sodium carbonate, 0.02mol / L nano-α-type iron oxide with a diameter of 5-10nm, 0.2mol / L iron humate, and 0.001mol / L formic acid , diethylsulfoxide 0.001mol / L, and the balance is water. The preparation method is simple mixing.

[0047] Using the prepared absorption liquid to carry out gas desulfurization according to the same method as in Example 1, the difference is that the feed gas contains 3g / m 3 Hydrogen sulfide nitrogen, the gas flow rate is 1600L / hr.

[0048] The sulfur content in the purified gas was analyzed, and the analysis results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com