Carbon fiber surface modification method

A surface modification, carbon fiber technology, applied in the direction of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems of uncontrollable distribution and arrangement of functional groups on the surface of carbon fiber, unfavorable carbon fiber interface mechanism research, etc., to increase wettability And the two-phase interface adhesion, improving the interfacial shear strength, the effect of improving the interfacial shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

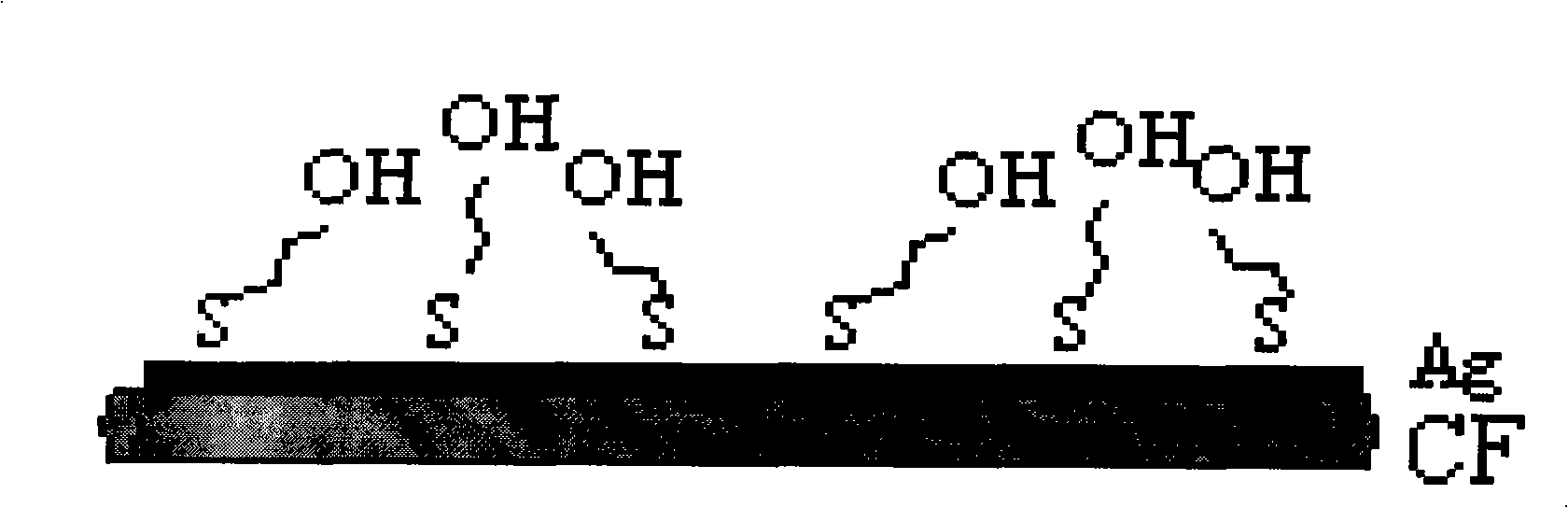

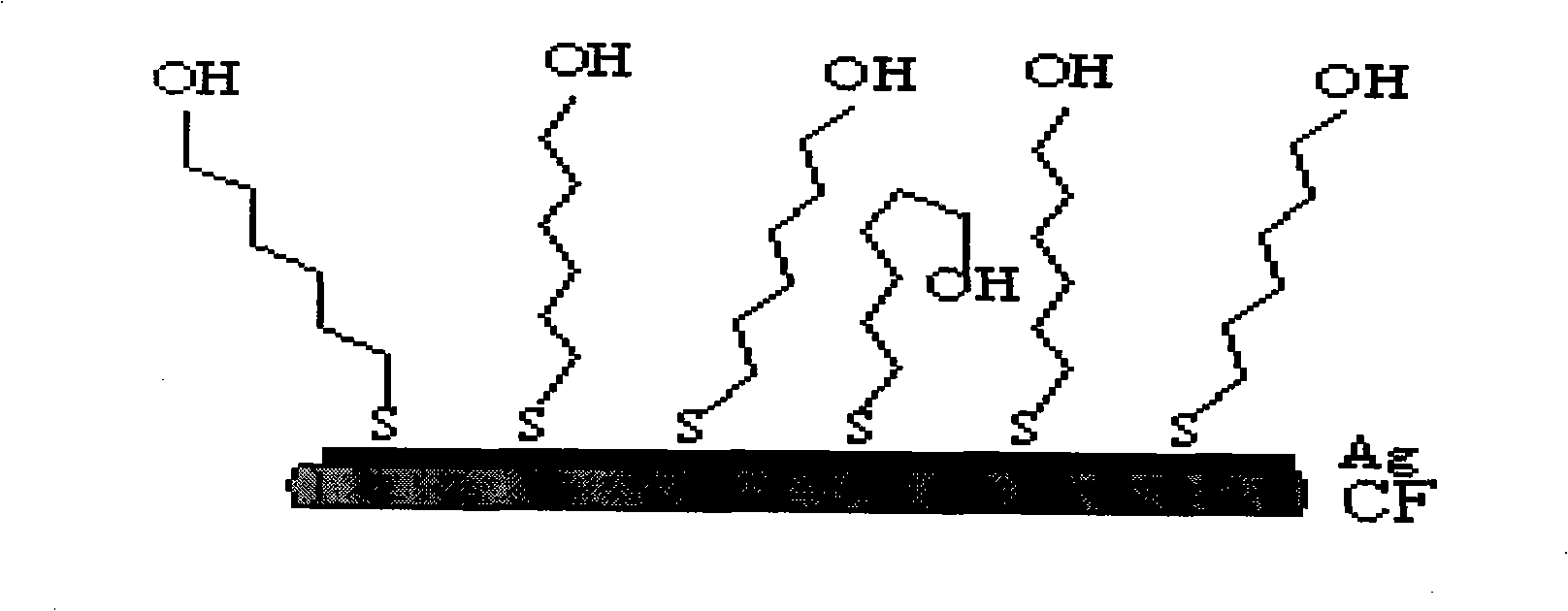

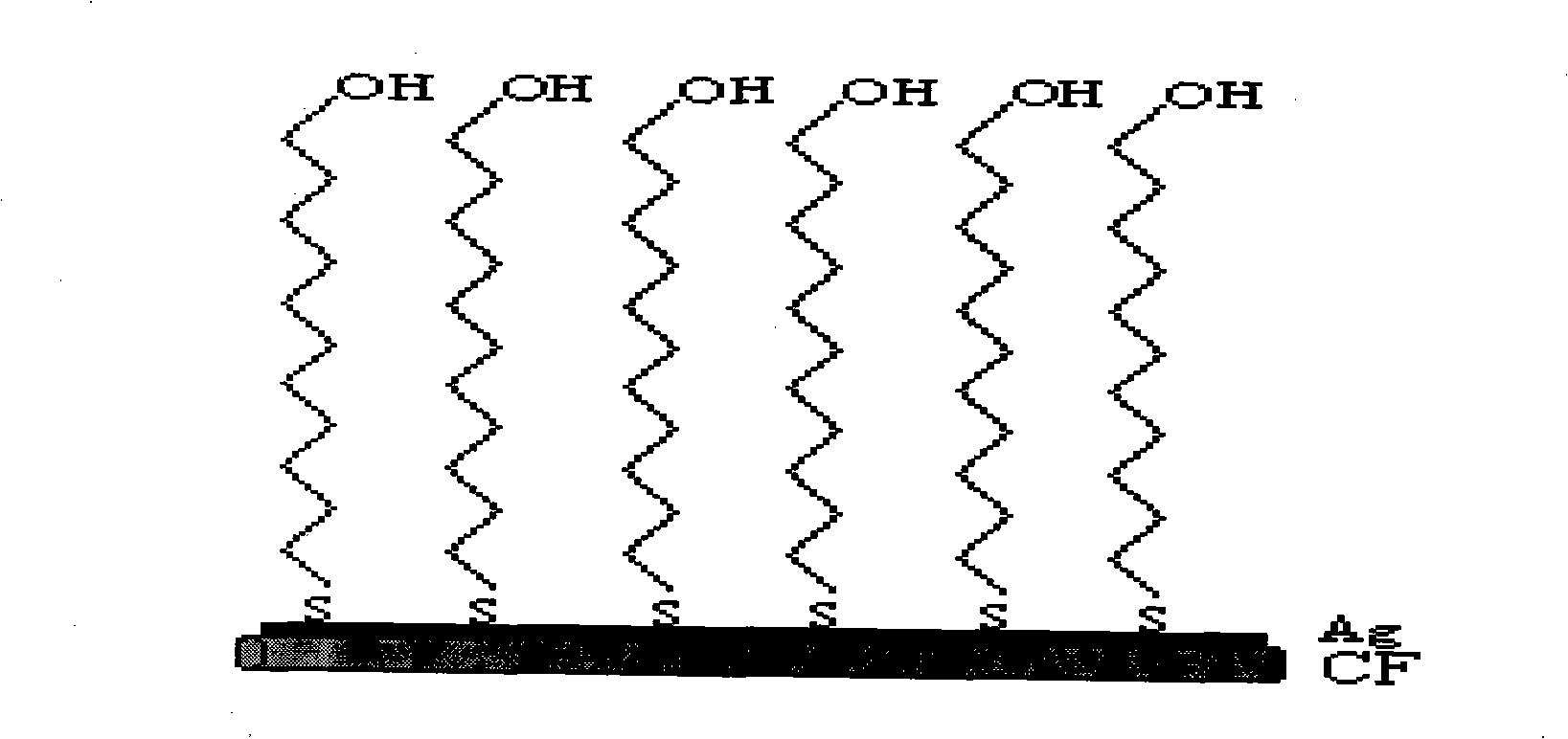

[0019] Embodiment 1: In this embodiment, the carbon fiber surface modification method includes two steps: 1. Electroless silver plating is performed on the carbon fiber surface; 2. Molecular self-assembly of organic sulfide is performed on the silver-plated carbon fiber.

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the chemical silver plating process of carbon fibers includes two steps of material surface pretreatment and chemical silver plating. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the surface pretreatment of carbon fiber material is carried out according to the following steps: a, carbon fiber bundle is put into extraction device, extract 24h~96h under acetone boiling temperature , remove the carbon fiber surface coating; b. Under the condition of 30℃~80℃, immerse the decoated carbon fiber in the degreasing liquid and cook for 15min~60min for surface cleaning treatment; c. Put the surface cleaning treatment carbon fiber in HNO with a mass concentration of 25% to 40% 3 In the solution, soak for 5min to 20min at room temperature for roughening treatment; d. Neutralize the acid remaining in the depressions on the carbon fiber surface after roughening with NaOH solution with a mass concentration of 5% to 20%; e. Under the condition of ~40°C, put the neutralized carbon fiber into the sensitization solution with a pH of 0.6~2.0 and immerse it for 1.5min~10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com