Purification method of sulfur-containing organic waste gas

A waste gas and organic technology, which is applied in the field of purification of sulfur-containing organic waste gas, can solve problems such as pollution of sulfur-containing organic waste gas, achieve the effects of reducing operating costs, preventing the impact of stable operation, and good treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

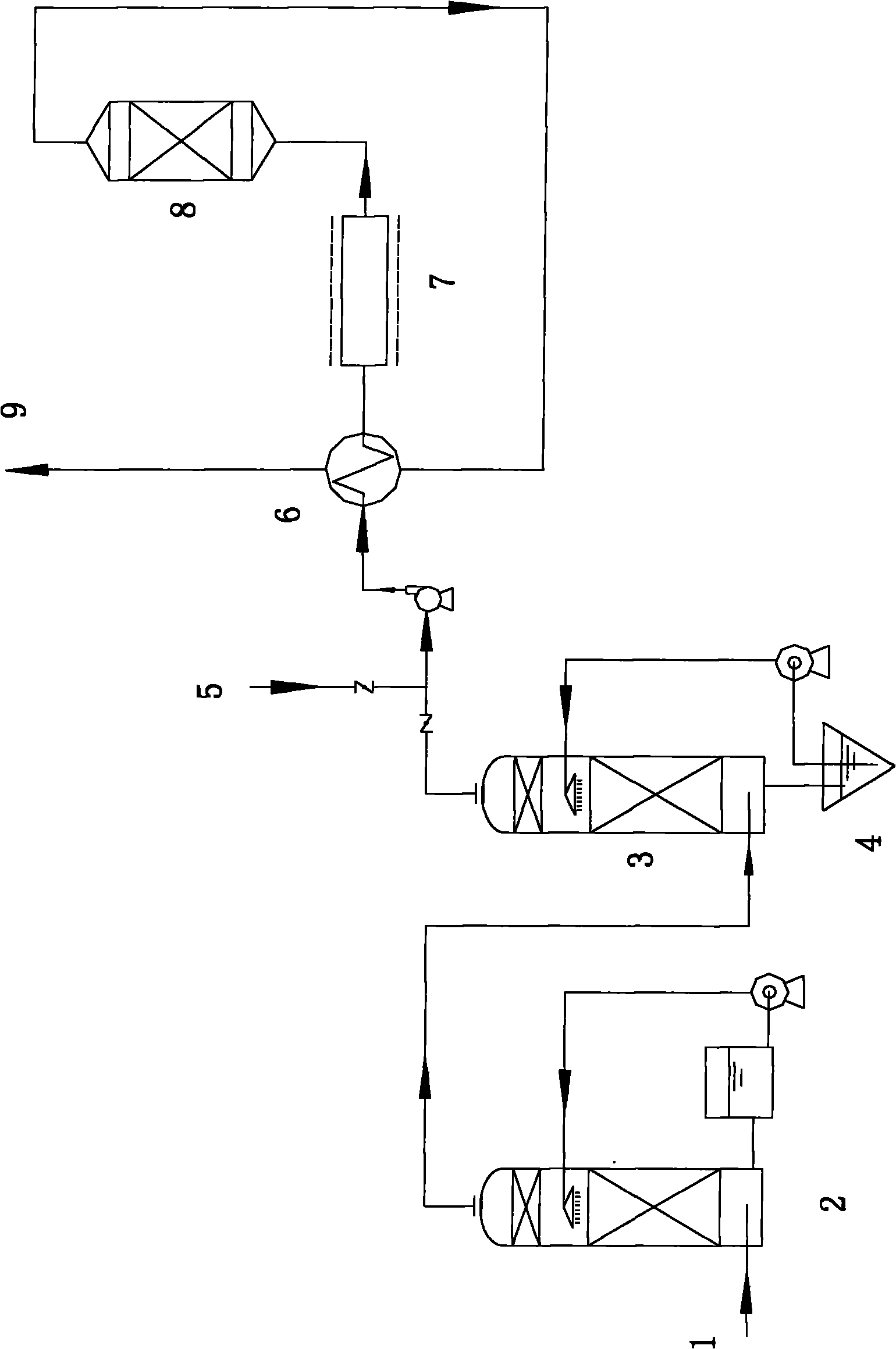

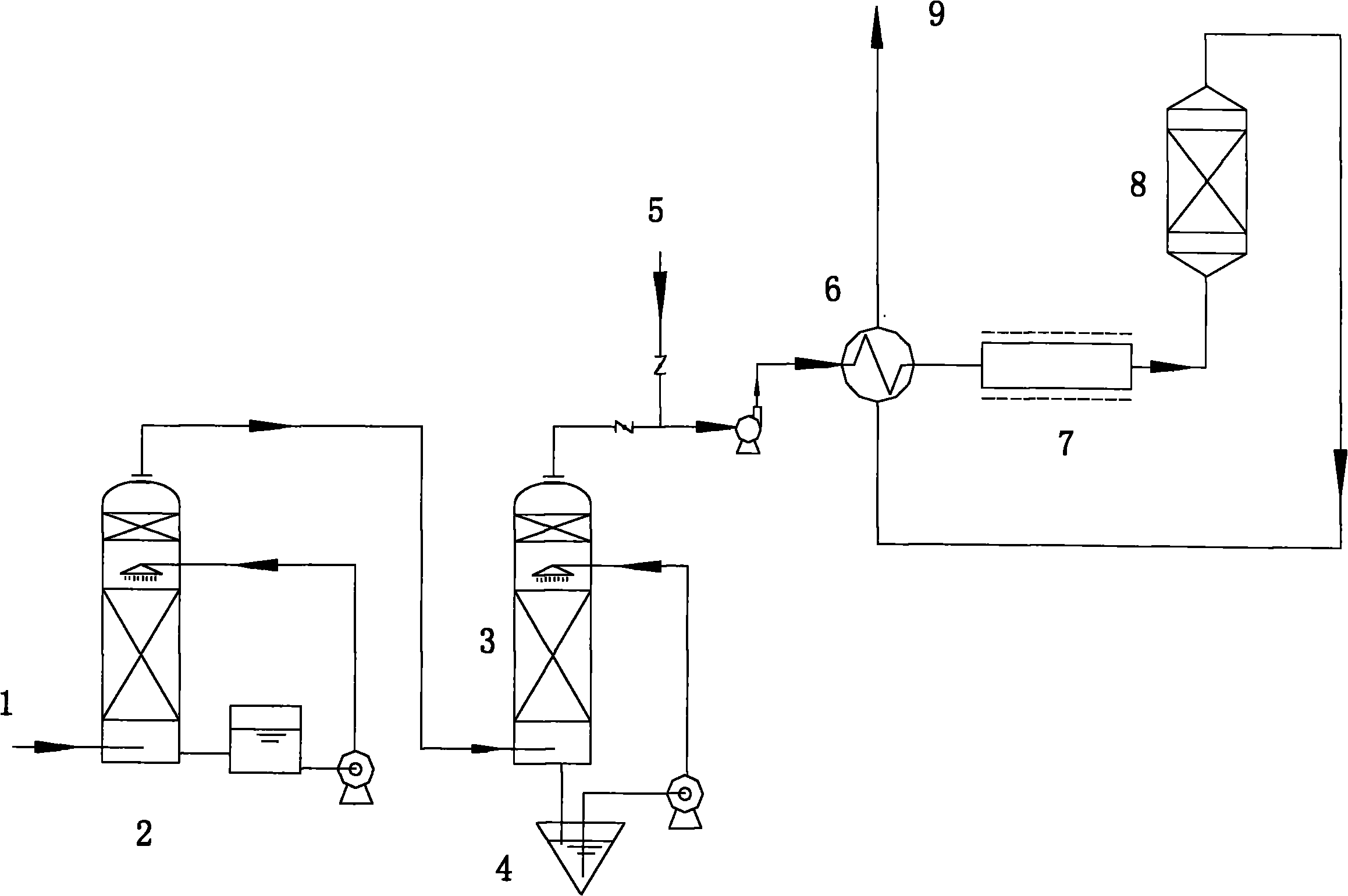

Method used

Image

Examples

Embodiment

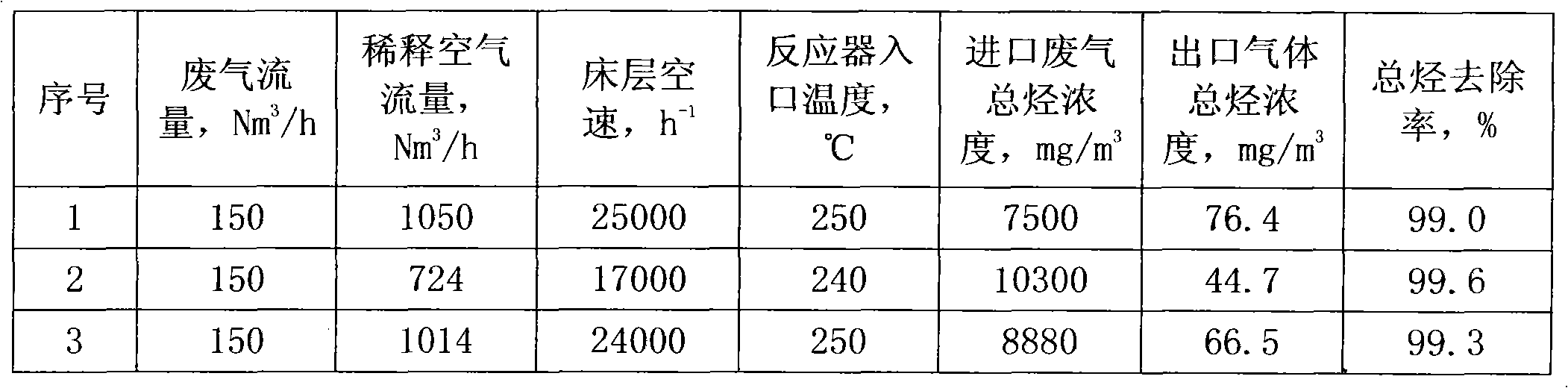

[0036] The acid water tank of a petrochemical enterprise has a volatilization amount of exhaust gas of 150Nm 3 / h, the total hydrocarbon concentration of the exhaust gas is 60,000 mg / m 3 , total sulfur concentration 6000mg / m 3 , of which the hydrogen sulfide concentration is 900 mg / m 3 , methyl mercaptan 450mg / m 3 , methyl sulfide 300mg / m 3 , dimethyl disulfide 1200mg / m 3 . The waste gas is treated by the process of "lye washing + sewage oil washing + catalytic combustion", in which, in the catalytic combustion unit, the catalysts used are precious metal Pt and Pd catalysts, and the flow rate of the dilution air is from 700Nm 3 / h to 1000Nm 3 / h varies. After two-stage washing pretreatment and air dilution, the total sulfur concentration and hydrogen sulfide concentration of the exhaust gas entering the reactor are both 10 mg / m 3 Below, the total hydrocarbon concentration is 12000mg / m 3 Below, the intake conditions of the catalytic combustion reactor are met.

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com