Hydrotreating method of acid-containing crude oil

A hydrogenation treatment and crude oil technology, applied in chemical instruments and methods, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of catalyst back-mixing, cumbersome loading and unloading of different types, etc., and achieve high hydrogenation activity, long operation period of the device, The effect of a good response channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058]Take by weighing silicon oxide content and be that the water glass 1000g of 30wt% adds in the beaker, start stirring device, slowly add mass concentration in the beaker and be the nitric acid solution 376g of 62%, the pH value of the water glass solution in the beaker after stirring and dissolving is 2.0, then Add 62.5g of nickel nitrate, and after dissolving, add 468g of pseudoboehmite (properties are as follows: pore volume 0.985mL / g, specific surface area is 313m 2 / g, dry basis is 72wt%), after stirring evenly, add 83g of curing agent urea, after the urea is completely dissolved, add deionized water, so that the material in the beaker is a paste with a certain fluidity, and silicon dioxide and oxide The solids content is 33% based on aluminum.

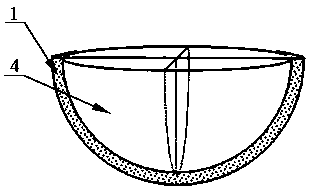

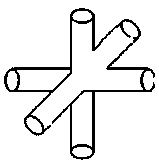

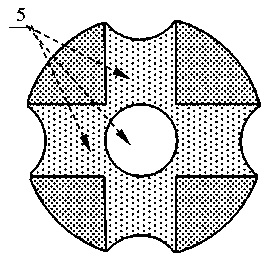

[0059] The above paste mass is pressed into two identical hemispheres with spherical cavities. Wherein, a guide mold is placed in a hemisphere, and the guide mold is made of wood. The structure of the guide mold is three cy...

Embodiment 2

[0064] The preparation process is as in Example 1, but the diameter of the spherical cavity of the mold and the diameter of the three cylinders in the guide mold are increased, and the prepared catalyst carrier B and catalyst B C The properties are shown in Table 1. The obtained catalyst carrier B had an outer diameter of about 7.6 mm and a through hole diameter of about 3.8 mm.

Embodiment 3

[0066] The preparation process is as in Example 1, except that nickel nitrate will not be added, and the solid content in terms of silica and alumina is 35%, the prepared catalyst carrier C and catalyst C C , Catalyst properties are shown in Table 1. Wherein, the outer diameter of the obtained catalyst carrier C is about 5.3 mm, and the diameter of the through holes is about 2.0 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com