Method for treatment of heavy hydrocarbon raw material with up-flow reactor

A reactor and hydrotreating technology, used in chemical instruments and methods, refined hydrocarbon oil, petroleum industry, etc., can solve the problems of complicated loading and unloading of different types, catalyst back-mixing, etc., and achieve good reaction channels, high hydrogenation activity, Long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Take by weighing 400 g of water glass with a silicon oxide content of 30 wt % and add it to the beaker, start the stirring device, slowly add 150 g of nitric acid solution with a mass concentration of 62% in the beaker, then add 42.9 g of nickel nitrate, stir and dissolve the water glass solution in the beaker The pH value is 2.0, then add 385.3g pseudo-boehmite (the properties are as follows: pore volume 1.05mL / g, specific surface area is 306m 2 / g, dry basis is 70wt%), after stirring evenly, add 35g of curing agent urea, after the urea is completely dissolved, add deionized water, so that the material in the beaker is a paste with certain fluidity, and silicon dioxide and oxide The solids content is 33% based on aluminum.

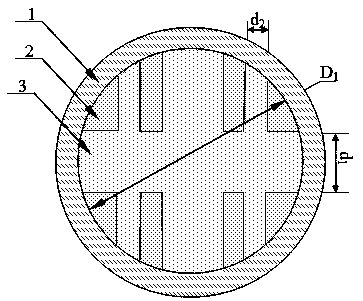

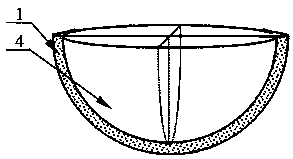

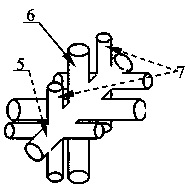

[0050] The above paste mass is pressed into two identical hemispheres with spherical cavities. Wherein, a guide mold is placed in a hemisphere, and the guide mold is made of wood. The structure of the guided mode is that there is a cylinder in th...

Embodiment 2

[0055] The preparation process is as in Example 1, except that the solid content of silica and alumina is 35%, and the mold is replaced, the diameter of the cavity and cylinder is increased, and the prepared catalyst carrier B and catalyst B C, whose properties are shown in Table 1. Wherein, the outer diameter of the obtained catalyst carrier B is about 9.5 mm, the diameter of the middle through hole is about 3.0 mm, and the diameter of the side through hole is about 1.6 mm.

Embodiment 3

[0057] The preparation process is as in Example 1, except that nickel nitrate is not added, the prepared catalyst carrier C and catalyst C C , whose properties are shown in Table 1. Wherein, the outer diameter of the obtained catalyst carrier C is about 7.0 mm, the diameter of the middle through hole is about 1.9 mm, and the diameter of the side through hole is about 1.3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com