Tin-containing desulfurization adsorbent and preparation method and application thereof

An adsorbent, content technology, applied in chemical instruments and methods, refined hydrocarbon oil, other chemical processes, etc., can solve the problems of small pore volume of adsorbent, reduced desulfurization activity, reduced adsorbent activity, etc., and achieve large pore volume. , The effect of high activity stability and high activity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 3.30 kg of crystalline tin tetrachloride (SnCl 4 .5H 2 O, Alfa Aesar company, 99%) was slowly added into 3.2 kilograms of acidic waters, and stirred slowly to avoid the precipitation of tin oxide crystals to obtain a colorless and transparent tin sol.

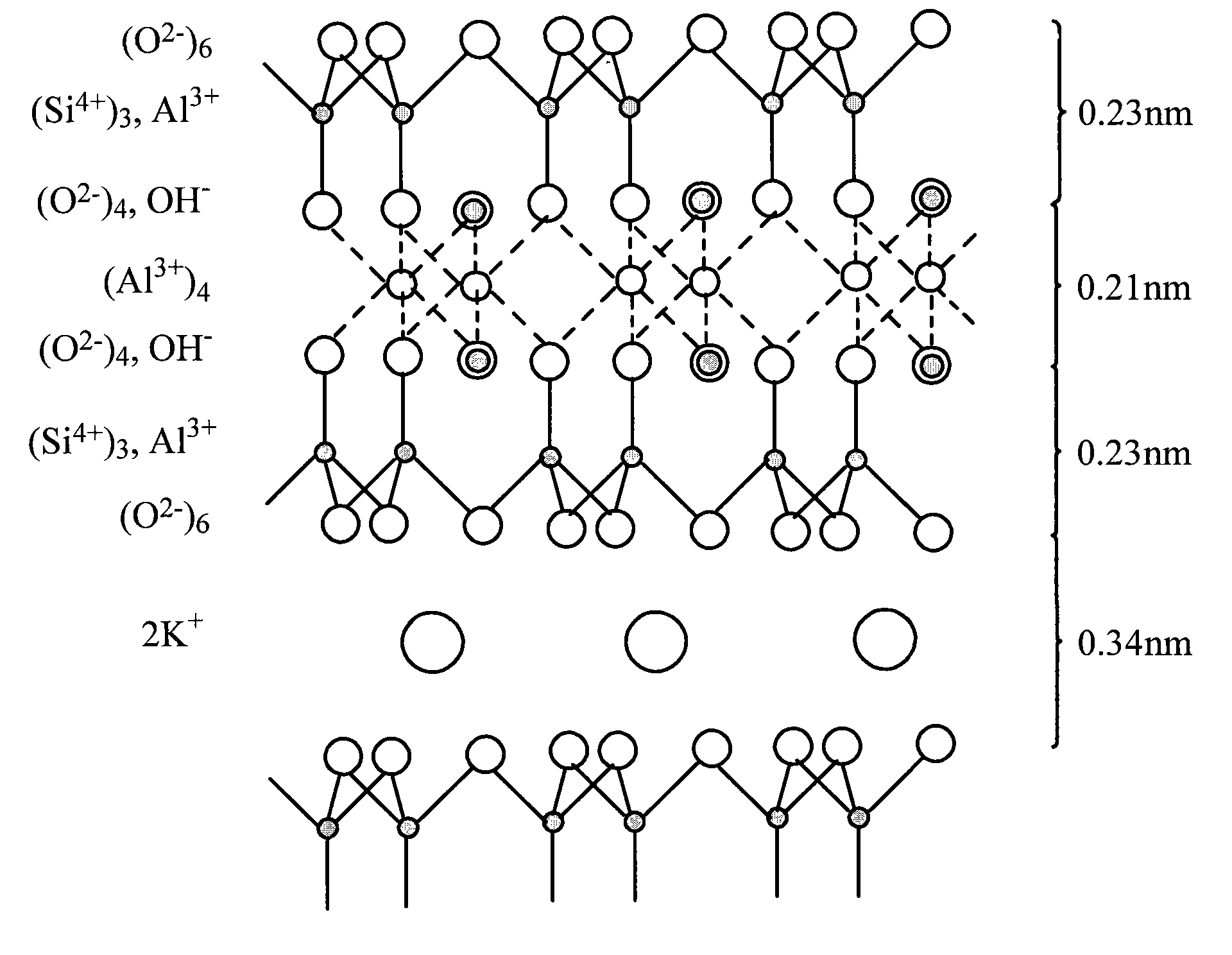

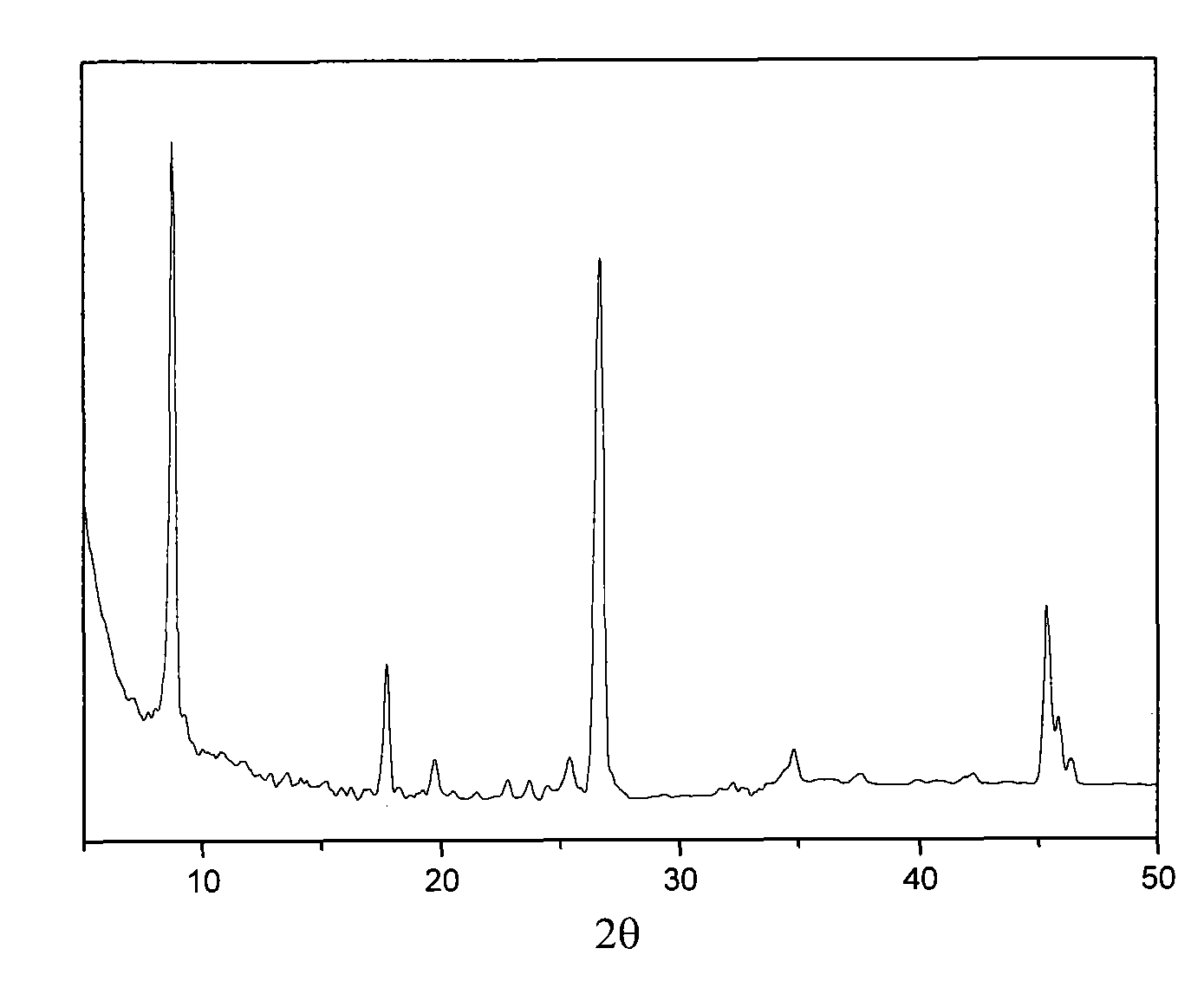

[0056] 5.55 kg of zinc oxide powder (produced by Beijing Chemical Plant, containing 5.38 kg on a dry basis) and 10.8 kg of deionized water were mixed, and after stirring for 30 minutes, a zinc oxide slurry was obtained; 2.11 kg of muscovite (containing a dry basis) were added to the zinc oxide slurry. 1.84 kg), and stirred for 15 minutes. Then the above tin sol was added, mixed and then stirred for 1 hour to obtain a carrier mixture slurry.

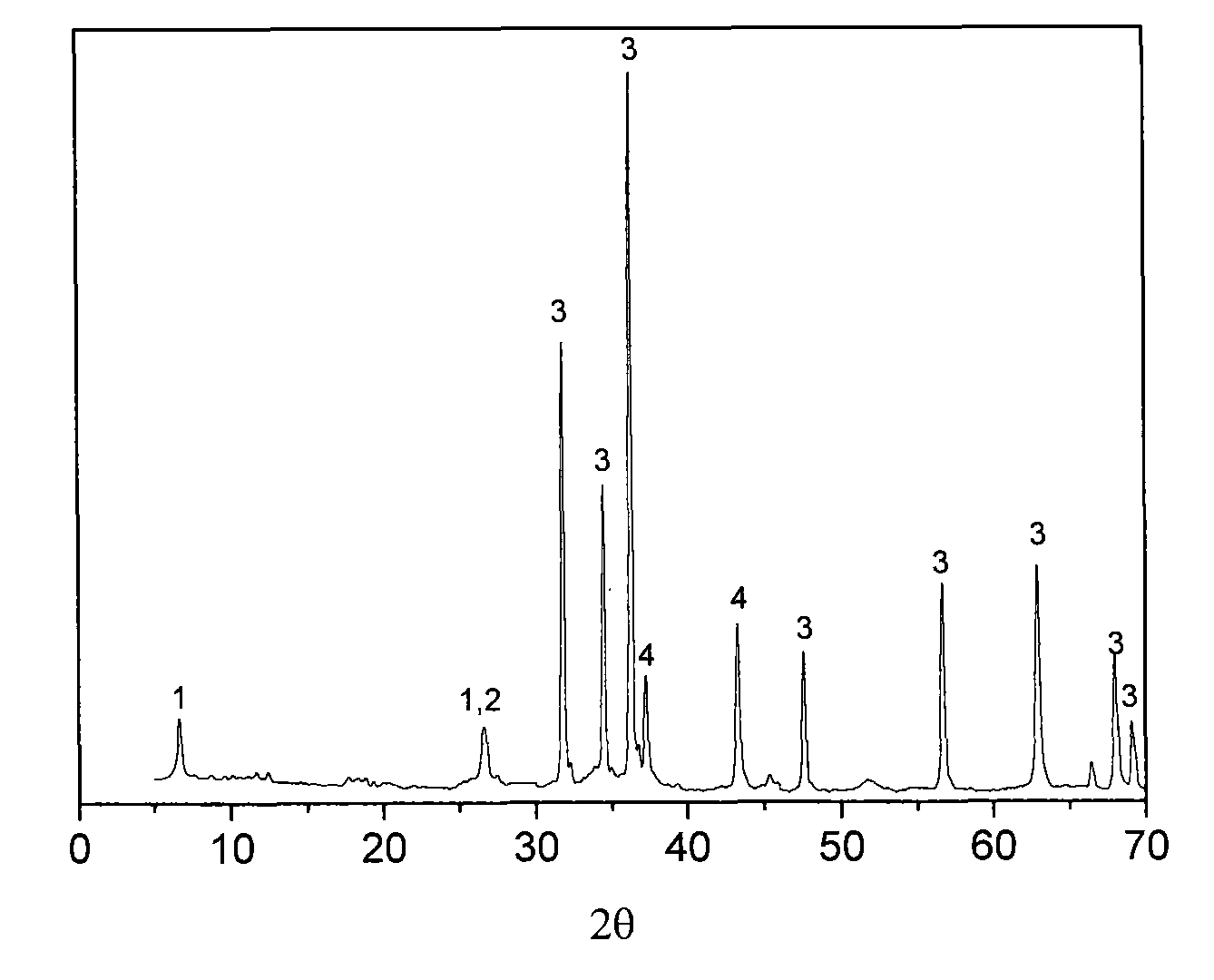

[0057] The carrier slurry uses Niro Bowen Nozzle Tower TM The model spray dryer is used for spray drying, the spray drying pressure is 8.5 to 9.5MPa, the inlet temperature is below 500°C, and the outlet temperature is about 150°C. The microspheres obtained by spray drying were f...

Embodiment 2

[0061] 2.52 kg of tin acetate (Aldrich company, analytically pure, 99%) was slowly added to 3.2 kg of 5% hydrochloric acid (chemically pure, produced by Beijing Chemical Plant) solution under stirring and stirred for 1 hour, the solution was white now sol state.

[0062] 4.88 kg of zinc oxide powder (produced by Beijing Chemical Plant, containing 4.73 kg on a dry basis) and 3.01 kg of muscovite (containing 2.62 kg on a dry basis) were added to 10.8 kg of deionized water, and stirred for 30 minutes. Then add the above-mentioned hydrolyzed tin sol, mix and stir for 1 hour to obtain carrier mixture slurry.

[0063] Referring to the method of Example 1, the carrier was spray-dried and molded and the active component nickel was introduced to obtain the adsorbent A2. The main chemical composition of the adsorbent A2 is: the content of zinc oxide is 47.3wt%, the content of tin dioxide is 10.7wt%, the content of muscovite is 26.2wt%, and the nickel (calculated as metallic nickel) is ...

Embodiment 3

[0065] 3.30 kg of tin acetate (Aldrich company, analytically pure, 99%) was slowly added to 3.2 kg of 5% hydrochloric acid (chemically pure, produced by Beijing Chemical Plant) solution under stirring and stirred for 1 hour, and the solution was white at this time colloidal solution.

[0066] 5.55 kg of zinc oxide powder (produced by Beijing Chemical Plant, containing 5.38 kg on a dry basis) and 1.38 kg of muscovite (containing 1.20 kg on a dry basis) and 0.67 kg of expanded perlite (containing 0.64 kg on a dry basis) were added to 10.8 kg of deionized water, and stir to mix for 30 minutes. Then add the above-mentioned hydrolyzed tin sol, mix and stir for 1 hour to obtain carrier mixture slurry.

[0067]Referring to the method of Example 1, the carrier was spray-dried and molded and the active component nickel was introduced to obtain the adsorbent A3. The main chemical composition of adsorbent A3 is: zinc oxide content is 53.8wt%, and the content of tin dioxide is 14.0wt%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com