Anode for lithium secondary battery and lithium secondary battery

A lithium battery and positive electrode technology, which is applied in the positive electrode field of the battery, can solve the problems of non-corrosion resistance and undurable current collectors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] [Production of current collector]

[0103] 20% by weight of graphite with an average particle diameter of 5 μm, 20% by weight of carbon black, 20% by weight of polyamideimide resin (trade name: N8020 manufactured by Toyobo Co., Ltd.), 40% by weight of solvent N-methyl - 2-Pyrrolidone (NMP) is fully mixed to prepare a slurry. This slurry is applied on the surface of a conductive substrate made of aluminum (Al) foil manufactured by Nilaco Co., Ltd. with a bar to form a predetermined film thickness, then preheated at 150°C for 1 hour, and then heated at 200°C It was cured for 1 hour to form a current collector. At this time, the above-mentioned aluminum foil is not subjected to special surface treatment, but is used as it is.

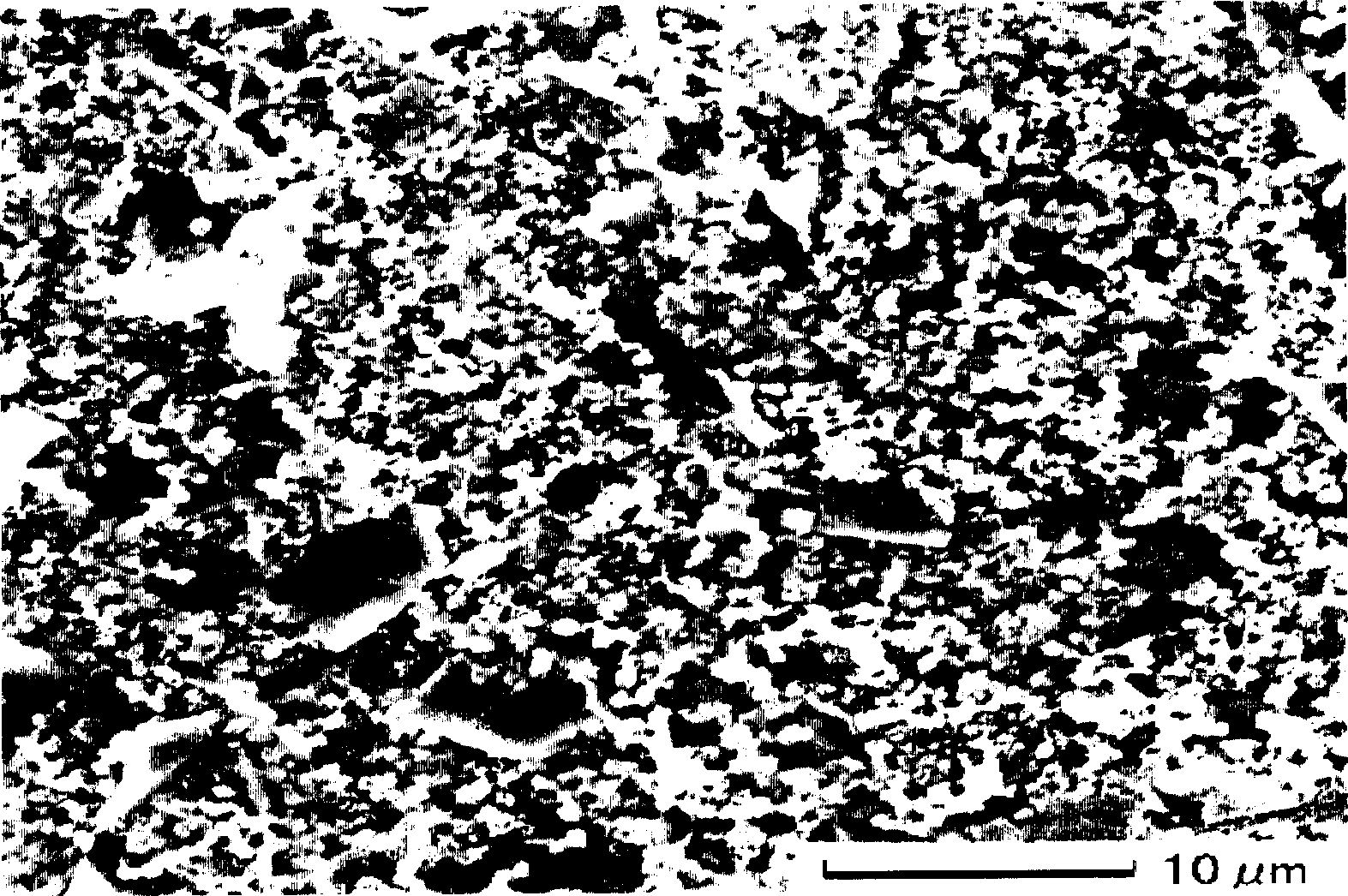

[0104] In the obtained current collector, a carbon-based material film having a thickness of 10 to 30 μm was formed on the surface of a conductive substrate formed of aluminum foil. figure 1 is a photograph of the surface of the current collector...

Embodiment 2

[0116] [Production of current collector]

[0117] A carbon-based conductive paint ink (manufactured by Acheson Corporation, trade name: EB-815) was used as the slurry. The ink contains: 5-20% by weight of artificial graphite; 5-20% by weight of carbon black; 5-20% by weight of polyamide imide resin; 0-1% by weight of butyral resin; N-methylpyrrolidone solvent . Apply this carbon-based conductive paint ink on the entire surface of a conductive substrate formed of 40 μm thick Al foil (H8079 material) with a direct gravure coating device, preheat at 150°C for 1 hour, and then heat at 250°C Under heating for 30 minutes to solidify to form a current collector.

[0118] In the obtained current collector, a carbon-based material film having a thickness of 5 to 20 μm was formed on the surface of a conductive substrate made of aluminum foil. This carbon-based material film has carbon-based material particles with an average particle size of 10 μm, and the weight ratio of carbon-base...

Embodiment 3

[0130] A current collector was produced by forming a carbon-based material on the surface of the substrate in the same manner as in Example 2, except that a titanium (Ti) foil having a thickness of 15 μm was used as the conductive substrate. Using this current collector, a three-electrode electrolyte battery was produced in the same manner as in Example 2, and electrochemical measurements were performed. As a result, the same characteristics as in Example 2 using Al foil as the conductive substrate were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com