Electrolyte for Li-S battery, preparation method thereof, and Li-S battery containing same

An electrolyte and battery technology, applied in the field of electrolyte, can solve the problems of reducing battery energy density and cycle life, polysulfide lithium cannot completely convert solid products, and low energy density of lithium-sulfur batteries, so as to reduce irreversible oxidation and improve quality and use performance, reduce the effect of irreversible loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

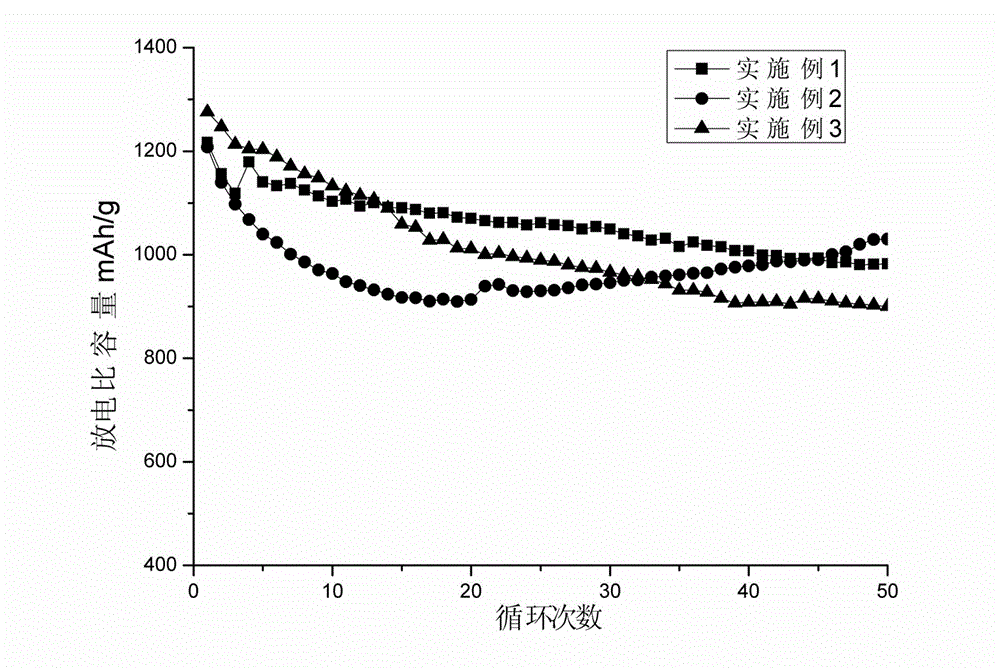

Embodiment 1

[0032] A kind of electrolytic solution that the present invention is used for Li-S battery mainly is made up of electrolytic salt and organic solvent, and this electrolytic salt is lithium polysulfide, and its molecular formula is Li 2 S 8 , the molar concentration of lithium polysulfide in the electrolyte is 1M in terms of sulfur; the organic solvent is a mixture of 1,3-dioxolane and ethylene glycol dimethyl ether, 1,3-dioxolane and ethylene glycol dimethyl ether The volume ratio of alcohol dimethyl ether is 1:1, and 0.1M LiNO is added to the electrolyte 3 As a Fraxel inhibitor.

[0033] The preparation method of the above-mentioned electrolytic solution in this embodiment includes the following steps: adding metal lithium and elemental sulfur to 1,3-dioxolane and ethylene glycol dimethyl in a volume ratio of 1:1 according to the molar ratio of 1:4 In a mixed solvent of ether, the reaction is carried out at room temperature or at a heating temperature lower than 100°C under...

Embodiment 2

[0041] A kind of electrolytic solution for Li-S battery of the present invention is mainly made up of electrolytic salt and organic solvent, and this electrolytic salt is lithium polysulfide, and its molecular formula is Li 2 S 4 , the molar concentration of lithium polysulfide in the electrolyte is 1M in terms of sulfur; the organic solvent is a mixture of 1,3-dioxolane and ethylene glycol dimethyl ether, and 0.1M LiNO is added to the electrolyte 3 As a Fraxel inhibitor.

[0042] The preparation method of the above-mentioned electrolyte solution in this embodiment includes the following steps: adding metal lithium and elemental sulfur to 1,3-dioxolane and ethylene glycol dimethyl in a volume ratio of 1:1 according to the molar ratio of 1:2 In a mixed solvent of ether, the reaction is carried out at room temperature or at a heating temperature lower than 100°C under the protection of an inert atmosphere. After the reaction is completed, the shuttle inhibitor LiNO 3 dissolved...

Embodiment 3

[0046] A kind of electrolytic solution for Li-S battery of the present invention is mainly made up of electrolytic salt and organic solvent, and this electrolytic salt is the mixture of polysulfide lithium of two kinds of different molecular weights, and its molecular formula is respectively Li 2 S 4 and Li 2 S 8 , the molar ratio of the two polysulfide lithiums is 1:1, the total molar concentration of the two polysulfide lithiums in the electrolyte is 1M in terms of sulfur element; the organic solvent is 1,3-dioxolane and ethylene glycol di A mixture of methyl ether and 0.1M LiNO was added to the electrolyte 3 As a Fraxel inhibitor.

[0047] The preparation method of the above-mentioned electrolyte solution of this embodiment includes the following steps: firstly, according to the preparation method of the electrolyte solution in Example 1, the 3 and 1M Li 2 S 8 (the molar concentration of polysulfide lithium is calculated as sulfur element), and then according to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com